Maintaining Your Outboard’s Gearcase: Mercury vs. Yamaha

- Mercury vs. Yamaha Maintenance Intervals

- What You're Actually Checking

- Design Differences That Matter

- Step-by-Step: Filling the Gearcase

- Oil Specifications

- Verification After Filling

- Troubleshooting: Stuck Drain Screws

- Missing Step: Propeller Removal

- Diagnosing Noises

- Pressure Testing

- Mercury vs. Yamaha: What We See in the Shop

- Non-OEM Parts

- Maintenance Kits

- When to Pull the Lower Unit

If your gearcase oil looks like chocolate milk or you're hearing grinding noises, you've got a problem. The gearcase transfers engine rotation to the prop and houses the water pump impeller. Without regular maintenance, you're looking at a seized lower unit or blown seals.

Mercury vs. Yamaha Maintenance Intervals

Both brands follow the same basic schedule. New outboards get their first gear oil change at 100 hours, then every 100 hours or annually after that, whichever comes first. Mercury and Yamaha both publish these intervals in their service guides.

Yamaha adds an earlier check at 20 hours on new engines to catch any break-in debris. Smart move—I've pulled metal shavings at that first service more times than I can count.

What You're Actually Checking

Every oil change is a diagnostic. You're not just swapping fluid.

Mercury Inspection Points

Pull the magnetic drain screw and look at it. A light coating of fine metallic "flour" is normal, especially in the first 100 hours. Bigger chunks or slivers mean gear damage. The Mercury maintenance guide flags this as your primary wear indicator.

Check the oil color. Milky or gray means water intrusion—bad seals or a cracked housing. You need to fix that before corrosion eats the gears.

Yamaha Inspection Points

Same deal with the magnetic lower plug—metal debris tells you what's happening inside. Yamaha's documentation says up to 10% water in the oil is "normal." I don't like any water in there, spec or not. Water causes rust and breaks down the lube. If I see it, I'm hunting for the leak.

Design Differences That Matter

Mercury's Command Thrust Option

Mercury offers a standard gearcase and an optional Command Thrust unit for bigger boats. The Command Thrust uses a 4.9-inch diameter case with 2.33:1 gear ratios (on some models), compared to the smaller standard case. It's built to push heavier loads—pontoons, big center consoles—with more torque at lower speeds. Wave to Wave's comparison breaks down the specs.

| Gearcase Type | Case Diameter | Typical Gear Ratio | Application |

|---|---|---|---|

| Mercury Standard | ~4.25" | 2.00:1 - 2.07:1 | Standard boats |

| Mercury Command Thrust | 4.9" | 2.33:1 | Heavy boats, pontoons |

The larger case means different oil capacity and different torque specs for the drain plugs.

Yamaha's Durability Focus

Yamaha builds for longevity. Their gearcases use corrosion-resistant materials throughout and heavy-duty sealing. Industry comparisons note Yamaha's "sturdy gearcases" as a core feature. They're quiet, they last, and they take saltwater abuse well.

Mercury counters with their Advanced MidSection (AMS) design, which adds structural rigidity to the entire lower unit assembly.

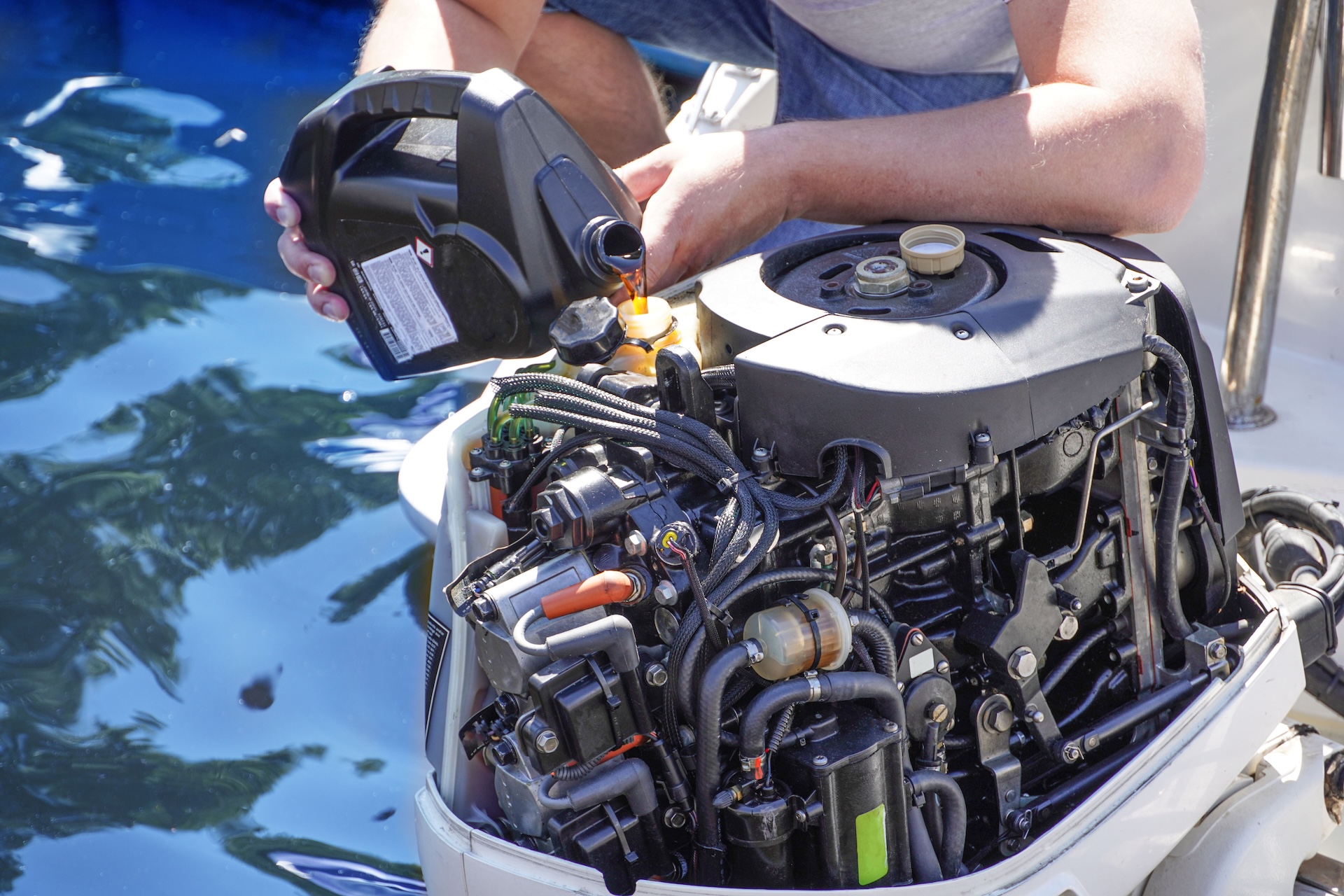

Step-by-Step: Filling the Gearcase

You need the right pump for your brand. Mercury and Yamaha fittings are different.

Required Tools and Specs

Tools:

- Brand-specific gear lube pump (Mercury or Yamaha)

- 3/8" socket or wrench (most drain/vent plugs)

- Torque wrench

- Gasket pick or dental pick for old washers

- Shop rags

Torque Specifications:

- Mercury drain/vent plugs: 20-25 ft-lbs (verify your model's manual—some smaller units use 18 ft-lbs)

- Yamaha drain/vent plugs: 22 ft-lbs (most models)

Oil Capacity (approximate):

- 115-150 HP class: ~20-24 oz

- 200-250 HP class: ~28-32 oz

- 300+ HP class: ~40+ oz

Check your specific model. Overfilling causes pressure; underfilling starves the gears.

Mercury Filling Procedure

- Remove the vent screw (upper) and drain screw (lower). Save the old crush washers—you'll replace them, but they tell you the right size.

- Let the old oil drain completely. Inspect it and the magnetic screw.

- Attach the Mercury gear lube pump to the lower (drain) hole.

- Pump slowly until fresh oil appears at the upper (vent) hole. Stop.

- Install a new crush washer on the vent screw and thread it in. Don't tighten yet.

- Keep pumping until oil seeps past the vent threads.

- Tighten the vent screw to spec (20-25 ft-lbs).

- Remove the pump. Install a new crush washer on the drain screw and tighten to spec.

Yamaha Filling Procedure

- Remove both plugs. Drain. Inspect.

- Attach the Yamaha pump to the lower fitting.

- Pump Yamalube Marine Gearcase Lube until it seeps from the upper hole.

- Wait 5 minutes. This lets air pockets escape.

- Pump again until oil seeps. Install the upper plug with a new crush washer.

- Remove the pump and install the lower plug with a new washer. Torque to 22 ft-lbs.

Critical: Replace the crush washers every time. Reusing them is asking for a leak. Part numbers are in your owner's manual.

Oil Specifications

Don't mix brands or types.

Mercury: Use Mercury Premium or High Performance Gear Lube. The Premium (blue) is SAE 90, GL-5 rated. High Performance (green) is synthetic blend for high-output engines. Don't guess—check your manual for your engine's spec.

Yamaha: Use Yamalube Marine Gearcase Lube. It's SAE 90, GL-4/GL-5 rated, formulated for Yamaha's seal materials.

Mixing synthetic and mineral oils causes additive conflict and seal swelling. Stick to one type.

Verification After Filling

Run the engine for 10 minutes, then shut down and let it sit for 5 minutes. Pull the vent screw again. Oil should be right at the threads. If it's low, you had an air pocket—top it off and check for leaks.

Troubleshooting: Stuck Drain Screws

If the drain screw won't budge, don't snap it off. Use an impact driver (the hammer kind, not electric) with the correct bit. Tap it sharply while turning. Heat from a propane torch helps if corrosion has welded it in—heat the boss around the screw, not the screw itself.

If it's stripped, you're drilling it out and retapping the hole. That's a shop job unless you have the right taps and time.

Missing Step: Propeller Removal

Before you even touch the drain screws, remove the propeller. You need to check the prop shaft seal for fishing line or debris. Line wraps around the shaft, cuts the seal, and lets water in. That's your milky oil right there.

Pull the prop. Inspect the shaft. If there's line embedded in the seal, dig it out carefully with a pick. Replace the seal if it's cut. For quality parts including seals and prop shaft components, look for options direct from the factory to ensure durability and fit.

Safety: Pull the battery terminal or remove the kill switch lanyard before working near the prop. I've seen props spin from a bumped shifter.

Diagnosing Noises

Not all gearcase noise is the same.

Prop chatter: A rhythmic vibration at low speeds, usually from a bent prop or debris on the blades. Pull the prop and check for dings.

Gear whine: A high-pitched whine under load, especially in forward. That's gear tooth wear or bearing failure. Metal on the drain screw confirms it. You're pulling the lower unit for a rebuild.

Clunking in neutral: Worn shift linkage or shift shaft seals. Not a gearcase lube issue—it's mechanical slop in the shifting mechanism.

Pressure Testing

After reassembly, a pressure test checks your seals. You pump the gearcase to 15-18 PSI (exact spec varies) and watch for pressure drop over 10 minutes. If it drops, you've got a leak—bad crush washer, prop shaft seal, or shift shaft seal.

Most DIYers don't have the pressure tester. If you're seeing repeated water intrusion, take it to a shop for the test. It's cheaper than guessing which seal failed.

Mercury vs. Yamaha: What We See in the Shop

Mercury's higher-output engines (Verado, Pro XS) run hotter and harder. We see more frequent lube changes on those—some owners go 50 hours in commercial use. The Command Thrust units take abuse well, but the larger case volume means you're buying more oil per change.

Yamaha's F-series are quieter and run cooler. They're easier on the gear lube. Fewer overheating-related seal failures. The downside: parts are sometimes metric threads where Mercury is SAE, so keep the right tools.

Neither brand has a durability edge if you maintain them. Neglect kills both equally.

Non-OEM Parts

You'll see cheap gearcase seal kits online. Don't. The rubber compound is wrong—too hard or too soft—and you'll be tearing the lower unit off again in six months.

OEM seals from Mercury or Yamaha fit right and last, but you're paying dealer markup. Quality aftermarket from manufacturers like JLM Marine offers factory-spec parts without the sticker price. Some of the same factories that produce OEM parts run aftermarket batches with the same tooling and materials.

For consumables like crush washers and basic seals, aftermarket is fine if the source is reputable. For precision parts like bearings or shift shafts, verify the tolerances.

Maintenance Kits

If you're doing annual service, a kit saves time. A good kit includes:

- Drain and vent crush washers

- Prop shaft seal

- Shift shaft seal

- Water pump impeller

- Impeller housing gasket

Verify the kit matches your engine's serial number range. Parts change mid-year on marine engines, and the wrong impeller diameter will cavitate. See our Water Pump Repair Kit vs. Impeller Only guide for detailed advice on choosing the right kit.

When to Pull the Lower Unit

If you're seeing:

- Milky oil after replacing seals

- Metal chunks (not fine dust) on the drain screw

- Grinding or clunking under power

- No water flow from the pee stream after impeller replacement

…you're pulling the lower unit. That's a bench teardown to inspect gears, bearings, and shift components. It's beyond a lube change. For in-depth repair, consult detailed outboard motor parts diagrams and catalogs to ensure correct reassembly and part sourcing.

At that point, take it to a shop unless you have the service manual, snap ring pliers, bearing pullers, and a press. Lower unit rebuilds aren't hard, but they require specific tools and shim measurements.

Pro tip: After every saltwater trip, flush the engine with fresh water using the flush port. That 5-minute habit prevents salt from crystallizing in the water passages and corroding the lower unit seals. It's the simplest thing you can do to avoid a gearcase tear-down. For more preventive care tips, see our Saltwater Use and Overheating: Prevention Tips.

Explore more about maintaining your marine engine and find quality parts and supplies direct from the manufacturer at JLM Marine.

For Mercury Owners:

To assist you in maintaining and repairing your marine engines, we hope the following resources may be of use:

-

Mercury / Mercruiser / Mariner Parts from JLM Marine

- Mercury Thermostat

- Mercury Water Pump

- Mercury Water Pump Impeller

- Mercury Water Pump Impeller Kit

- Mercury Carburetor

- Mercury Carburetor Repair Kit

- Mercury Fuel Pump

- Mercury Fuel Pump Kit

- Mercury Air Filter

- Mercury Oil Filter

- Mercury Oil Seal

- Mercury Fuel Filter

- Mercury Gasket

- Mercury Relay

- Mercury Ignition Switch

- Mercury Trim Tilt Switch

- Mercury Ignition Sensor

- Mercury Spark Plug Wire

- Mercury Water Distribution Housing

- Mercury Bellow

- Mercury Bellows Kit

- Mercury Serpentine Pulley

- Mercury Accessories

- Mercury Belt

- Mercury Oil Plug

- Mercury Drain Plug

- Mercury Bellows Replacement Tool

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.