Spare Prop and Shear Pins: Be Prepared on Vacations

- Shear Pins vs. Rubber Hubs: Know Your Motor

- Why Shear Pins Break and What Happens

- Don't Use Hardware Store Pins

- How to Replace a Shear Pin

- Spare Props: When You Need One

- What to Carry Onboard

- Where to Source Shear Pins and Props

- Troubleshooting: Pin vs. Hub vs. Gear Damage

- Rental Boats: Should You Fix It Yourself?

- How Often to Replace Shear Pins Preventatively

The two most common failures we see when folks hit something on vacation are propeller damage and shear pin breaks. Carrying spares and knowing how to swap them out can save you from a tow bill and days of downtime. I've been fixing outboards for 20 years, and the boats that limp back to the dock are almost always missing these basics in their toolbox.

Shear Pins vs. Rubber Hubs: Know Your Motor

Older and smaller outboards – typically under 20HP – use shear pins. These are brass or soft stainless pins that connect the prop to the shaft. They're designed to snap on impact, protecting your lower unit gears. When the pin breaks, you hear a loud bang, the engine revs freely, and you lose all thrust. The prop stays on the shaft but spins independently because the pin's gone.

Newer motors and larger outboards use a rubber hub insert inside the prop instead. When you hit something hard, the rubber spins inside the hub rather than transferring shock to the gearbox. If you own a modern 50HP Yamaha or Mercury, you don't have a shear pin – you have a hub. Check your owner's manual if you're not sure which system you've got, because the fix is completely different.

Why Shear Pins Break and What Happens

You slam into a submerged log, a rock shelf, or a sandbar at speed. The impact force has to go somewhere. The shear pin is engineered to be the weakest link – it breaks cleanly, usually right where it passes through the shaft. The U.S. Coast Guard reported 169 propeller strike accidents in 2024, with 30 fatalities and 158 injuries. Many of these incidents involve loss of propulsion after a strike, stranding boaters miles from shore.

The prop doesn't fall off when the pin shears. It remains mounted to the shaft, but the shaft spins inside the hub. You'll notice:

- Sudden loud thunk or bang

- Engine revs up without resistance

- No forward or reverse thrust

- Prop may wobble slightly if you look over the transom

If you keep trying to throttle up, you're just burning fuel. Shut it down and check the pin.

Don't Use Hardware Store Pins

You're stuck at a remote dock on Saturday, the marine shop is 40 miles away, and the hardware store across the street has nails and bolts. I get it. But don't do it.

Factory shear pins are made to specific alloys – usually soft brass or a specific grade of stainless – and precise diameters. A hardware store bolt might be Grade 5 or Grade 8 hardened steel, which won't shear when it should. Instead of breaking, it transfers the shock straight into your prop shaft or lower unit gears. I've pulled lower units where someone used a Grade 8 bolt as a "fix," and the splines on the shaft were stripped clean. That's a $600 repair instead of a $3 pin.

On the flip side, a cheap nail or cotter pin might be too soft and shear during normal operation, leaving you stranded again 10 minutes later.

Boating forums are full of guys who tried the hardware store route. One user on a popular forum described using a trailer hitch cotter pin on his Mariner 3.3. It worked for 20 minutes, then sheared unevenly and caused the prop to wobble so badly it chewed up the shaft splines. Another poster from Australia used a random bolt and ended up with a $850 lower unit rebuild. Stick to the right part.

Learn more about why it's important to avoid using automotive parts in your boat engine to protect your motor.

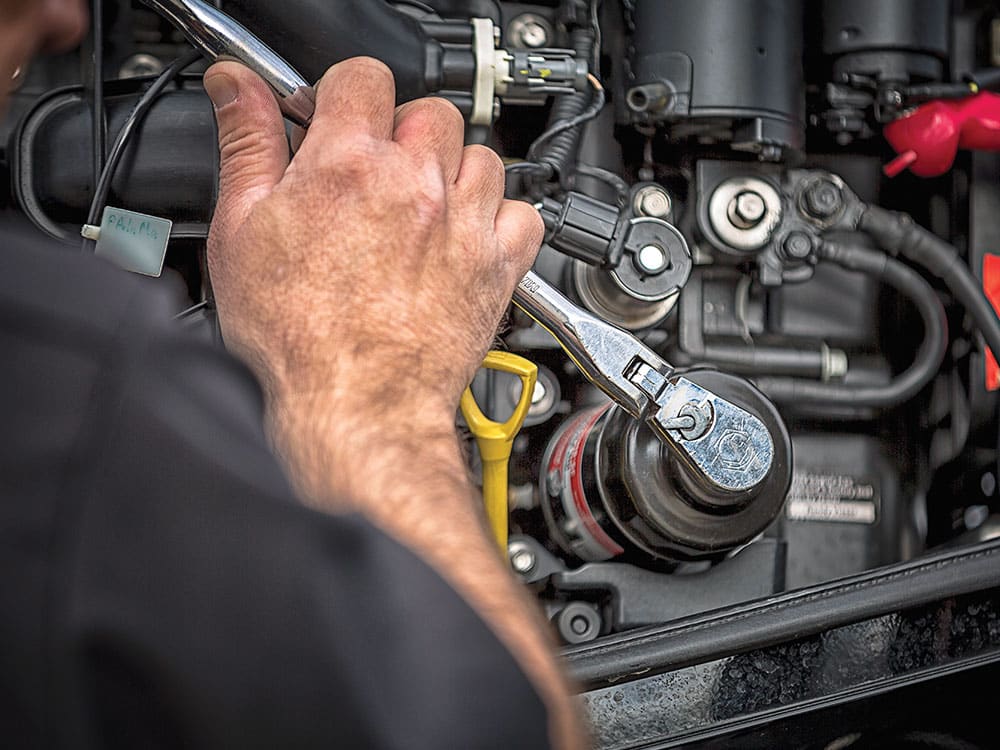

How to Replace a Shear Pin

This job takes 10 minutes if you've got the right tools and parts. Practice it once at home before your trip so you're not figuring it out in a rocking boat.

Tools you need:

- Prop wrench (usually 13mm or 1/2 inch, depending on motor)

- Small punch or 1/8 inch drift pin

- Pliers

- Block of wood (2x4 scrap works)

- Marine grease

- Replacement shear pin for your exact motor model

Steps:

Kill the engine and pull the spark plug wire. This prevents accidental starts while you're working near the prop.

Remove the prop nut with the prop wrench. If the prop spins while you're trying to loosen the nut, wedge the wood block between a prop blade and the cavitation plate to lock it in place. Keep track of the washer, thrust hub, and any cotter pins or locking tabs.

Pull the prop off the shaft. Sometimes it's seized on from corrosion. Tap it with the heel of your hand or use a rubber mallet. Don't pry with a screwdriver – you'll gouge the shaft.

Look for the shear pin hole that runs through the prop hub and shaft. You'll see broken pin fragments inside. Use the punch to tap out the old pieces from the opposite side. Needle-nose pliers can grab any remnants sticking out.

Slide the new shear pin through the aligned holes in the hub and shaft. It should sit flush on both sides. Don't force it – if it doesn't slide easily, the holes aren't lined up or there's debris inside.

Grease the prop shaft lightly with marine grease before reinstalling the prop. This prevents seizing, especially in saltwater. Slide the prop back on, ensuring the pin engages properly in the hub.

Reinstall the thrust washer, prop nut, and any locking hardware. Tighten the nut snug – don't crank it down with a breaker bar, but make it firm. Most small outboards spec around 20-25 ft-lbs, which is hand-tight with a standard wrench plus a bit more.

Reconnect the spark plug wire. Start the motor in a test tank or shallow water. Shift into forward and reverse at low RPM to verify thrust. Listen for any unusual clunking or grinding.

If the prop doesn't engage or you hear grinding, stop immediately. The pin might not be seated, or there's damage to the shaft splines that needs shop attention.

For additional guidance on maintenance, consider our Off-Season Outboard Maintenance Checklist to keep your motor ready year-round.

Spare Props: When You Need One

If you're running an aluminum prop on a budget outboard, carry a spare prop – not just a pin. Aluminum blades bend or break on hard strikes. A spare doesn't need to match your main prop's pitch perfectly. If your main is a 9-pitch and your spare is an 8-pitch, you'll run slightly slower, but you'll get home. An aluminum spare costs $40-$80, and Mercury recommends carrying one for exactly this reason.

For stainless props, the blades rarely break, but the hub can spin. Carry a spare hub insert if your prop uses a replaceable one. If you've got an inboard wakeboard boat, always pack a spare prop – blade strikes on ski lakes are common, and swapping the prop on the water beats a $500 tow.

Choosing the right prop for your boat can also be understood better by reviewing the guide on Comparing Propeller Pitches: Finding the Best Pitch for Your Boat.

What to Carry Onboard

For shear pin motors:

- 3-5 shear pins (they're small and cheap – no excuse not to carry extras)

- Prop wrench sized for your motor

- Small punch or drift pin

- Pliers

- Marine grease tube

- Spare prop nut and cotter pin

For rubber hub motors:

- Spare hub insert

- Full spare prop if budget allows

- Prop wrench

- Wood block

Keep these in a small waterproof bag or toolbox zip-tied under a seat. I've shipped parts to guys in the Florida Keys who learned this lesson the hard way – one called from a sandbar 12 miles offshore with a spun hub and no spare. His tow bill was $850, and he lost two days of his vacation waiting for the part.

For sourcing authentic and factory-spec parts like shear pins and props, JLM Marine offers direct-to-consumer boat parts that ship worldwide with no dealer markup.

Where to Source Shear Pins and Props

For shear pins, you need the exact size and material for your motor. A Yamaha 2.5HP uses a different pin than a Mercury 6HP. Don't guess. Check your owner's manual or the parts diagram for your model.

We stock factory-spec shear pins for most outboards at JLM Marine. These are made to the same tolerances as OEM, but we cut out the dealer markup by shipping directly from the factory. You get the right alloy, the right diameter, and the right length without paying triple for a branded box. We've sent pins to over 100 countries, and the feedback is consistent – they fit right and they work.

For props, the same rule applies. OEM props from a dealer are reliable, but you're paying a premium for the logo. Cheap no-name props from random sellers are a gamble – the pitch might be off, the hub might not seat properly, and you'll be pulling the lower unit apart again next season. Quality aftermarket suppliers like JLM Marine use the same factory specs as OEM without the dealership overhead, so you're getting the same part for 30-40% less.

Find more details in our Inboard & Outboard Motor Parts collection at JLM Marine.

Troubleshooting: Pin vs. Hub vs. Gear Damage

If you lose thrust after a strike, here's how to narrow down the issue:

Sheared pin: Engine revs freely, no thrust in forward or reverse, loud bang at the moment of impact. Prop still attached but spins loosely on the shaft when you try to turn it by hand (engine off).

Spun rubber hub: Similar symptoms to a sheared pin – engine revs, little to no thrust – but the prop doesn't spin completely free. You might get some weak propulsion at high RPM. The rubber inside the hub has torn loose from the outer shell. This happens on newer motors without shear pins.

Damaged lower unit gears: Grinding noise when you shift into gear, even at idle. Prop might engage intermittently or slip under load. This is bad – it means the impact shock made it past the pin or hub and damaged the gears. You'll need a shop for this one.

If the shear pin hole in the shaft is damaged or widened from repeated impacts, a new pin won't hold. You'll feel it slip under throttle. That's a machine shop fix – the shaft needs to be drilled out and a larger pin fitted, or the shaft replaced entirely.

For additional help diagnosing damage such as lower unit issues, see our guide on Grinding Noise in the Lower Unit: Signs of Gearbox Trouble.

Rental Boats: Should You Fix It Yourself?

If you're on a rental, call the marina before you start pulling props. Most rental agreements prohibit mechanical work by renters, and if you strip a shaft or cross-thread a prop nut, you're liable for the damage. That said, if you're stuck miles offshore and the rental company tells you to fix it yourself or pay for a tow, having a spare pin and knowing the process can save you hundreds. Just document everything with photos in case there's a dispute later.

How Often to Replace Shear Pins Preventatively

Shear pins don't wear out from normal use – they only break on impact. But if you operate in debris-heavy water (rivers, marshes, shallow lakes), some experienced boaters replace pins once a season or every 100 hours as preventative maintenance. The pin might have micro-cracks from previous strikes that didn't fully shear it. A fresh pin costs $2. A spun shaft costs $400. Do the math.

Before every trip, inspect your prop for nicks, bent blades, or fishing line wrapped around the hub. A damaged blade creates imbalance, which stresses the pin and can cause it to fail even without a strike. If the prop's dinged up, file down sharp edges or swap it out before you leave the dock.

Learn more about protecting your prop and maintaining smooth operation by checking out Propeller Slip or Engine Issue? When Your Boat Can’t Reach Speed.

Pro tip: Grease your prop shaft every time you pull the prop, even if it's just for inspection. Saltwater corrodes the shaft, and a seized prop is harder to remove than a sheared pin is to replace.

Explore more premium parts and expert advice at JLM Marine.

Hi—I’m Jim Walker

I grew up in a Florida boatyard, earning pocket money (and a few scars) by rebuilding outboard carbs before I could drive. That hands-on habit carried me through a Ph.D. in mechanical engineering, where I studied how salt water quietly murders metal.

I spent ten years designing cooling systems for high-horsepower outboards, then joined JLM Marine as CTO. We bench-test every new part in the lab, but I still bolt early prototypes onto my own 23-foot skiff for a weekend shake-down— nothing beats real wake and spray for finding weak spots.

Here on the blog I share the fixes and shortcuts I’ve learned so your engine—and your day on the water—run smooth.

For Boat Owners:

To assist you in maintaining and repairing your marine engines, we hope the following resources may be of use:

- Mercury Serial Number Guide

- Owner's Manuals from Mercury

- Official Model Number Reference Guide PDF from BRP

- Johnson Serial Number Guide

-

Boat Accessories from JLM Marine

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.