Can I Use Automotive Parts in My Boat Engine?

- The Core Problem: Sparks and Fuel Vapors

- Which Parts Are Never Swappable

- Which Parts Might Cross Over

- The Marinization Process

- Cooling System Differences

- ABYC and USCG Compliance

- Cost Reality Check

- What About Diesel Engines?

- Myth: "I'll Just Leave the Hatch Open"

- Real Parts Quality: OEM vs. Aftermarket

- Insurance and Survey Implications

- What If You Already Have Automotive Parts Installed?

- When You Might Marinize an Automotive Engine

- rpm and Load Differences

- Emergency Scenario: Can I Use an Auto Part Just to Get Home?

- Where to Source Correct Marine Parts

- Next Steps If Your Engine Is Blown

- FAQ

Short answer: for most critical parts, no. Long answer: it depends on the part, but if you're asking about anything electrical or fuel-related on a gasoline engine, still no.

I've watched guys try this swap for two decades. Sometimes they get away with it for a season. Sometimes the boat burns. The difference usually comes down to which specific parts they used and whether they understood ignition protection standards.

The Core Problem: Sparks and Fuel Vapors

Your car engine sits under a ventilated hood. Your boat engine sits in an enclosed bilge where gasoline vapors settle. That's the whole game right there.

U.S. Coast Guard regulation 33 CFR 183.410 requires ignition-protected electrical components in gasoline engine compartments. Marine starters, alternators, and distributors meet SAE J1171 standards—they're sealed to contain internal sparks and tested to specific surface temperature limits. Your automotive alternator has none of that. It might look identical. It'll bolt right on. But the brushes aren't sealed, the housing isn't spark-tight, and one spark in a vapor-filled bilge ends the conversation permanently.

I saw this exact scenario five years ago. Guy bought a used cruiser, swapped in an automotive starter to save $150. Ran fine for three months. Then a bit of fuel vapor accumulated one morning while he was cranking, and the non-sealed brush assembly sparked. Fireball. Thankfully he was dockside and got off, but the boat was a total loss. Insurance denied the claim when the surveyor found the automotive starter. That's a $40,000 lesson on a $150 part.

Which Parts Are Never Swappable

These components must be marine-rated on any gasoline boat with an enclosed engine space:

Starters – Marine units are built to SAE J1171 with sealed brush housings and vapor-tight construction. Automotive starters vent internally and will eventually spark where vapors collect.

Alternators – Same deal. Marine alternators are ignition-protected, meaning even if a diode fails or a brush arcs, the housing contains it. Automotive alternators are designed assuming clean, ventilated air.

Fuel pumps – Marine electric fuel pumps route any overflow back into the fuel system or are designed with sealed, spark-free motors. Many automotive pumps vent externally or aren't rated for marine vapor exposure. For sourcing the right parts, check out our fuel pump collection.

Carburetors and fuel-injection components – Marine versions are configured so leaks can't drip into the bilge. Automotive carbs often have external vents that'll dump raw gas below. See our carburetor selection for marine-rated options.

Distributors and ignition coils – Marine distributors have sealed caps and non-venting designs. Automotive units assume engine-compartment ventilation that doesn't exist in a boat.

Switches, relays, solenoids – Anything that can arc must be ignition-protected if it's in or near the engine or fuel tank space. Automotive versions aren't built for this.

Which Parts Might Cross Over

Internal engine wear parts that don't interact with fuel vapors or electrical systems can sometimes be shared if the base engine family is identical and the marine manufacturer explicitly cross-references them. This includes:

- Spark plugs (same heat range, but verify the ignition system they're attached to is marine-rated)

- Some oil filters and fuel filters (check OEM cross-reference lists), which you can browse in the fuel filter collection

- Certain mechanical components like bearings, gaskets, or seals in non-electrical assemblies

- Internal block parts (pistons, rods, valves) on engines that share the same long-block casting with a marinized version

Even here, you need to verify. Marine engines often use different cam profiles because boats run under constant load—like your car climbing a hill nonstop. An automotive cam with aggressive overlap can cause exhaust reversion in a marine application, sucking water back into the cylinders during deceleration. I've torn down two engines ruined this way.

Marine engines also swap out steel freeze plugs for brass or stainless to resist corrosion. If you rebuild an automotive block and leave steel plugs in, they'll rust through in saltwater. It's not dramatic—just slow expensive failure.

The Marinization Process

Companies like Jasper Engines rebuild automotive long blocks for marine use. Here's what actual marinization involves:

- Replace all freeze plugs with brass or stainless

- Swap the camshaft for a marine-profile cam with reduced overlap

- Install marine-rated ignition components (distributor, coil, wiring)

- Fit a closed cooling system with heat exchanger, or raw-water pump and corrosion-resistant passages

- Replace all electrical accessories (starter, alternator, voltage regulator) with SAE J1171-compliant units

- Reconfigure or replace the fuel system to meet ABYC E-1500 and USCG fuel-system standards

- Apply corrosion-resistant coatings and use marine-grade fasteners throughout

If you skip any of these steps, you've got an automotive engine in a boat, not a marine engine. The long block might be the same casting, but the periphery is where safety lives.

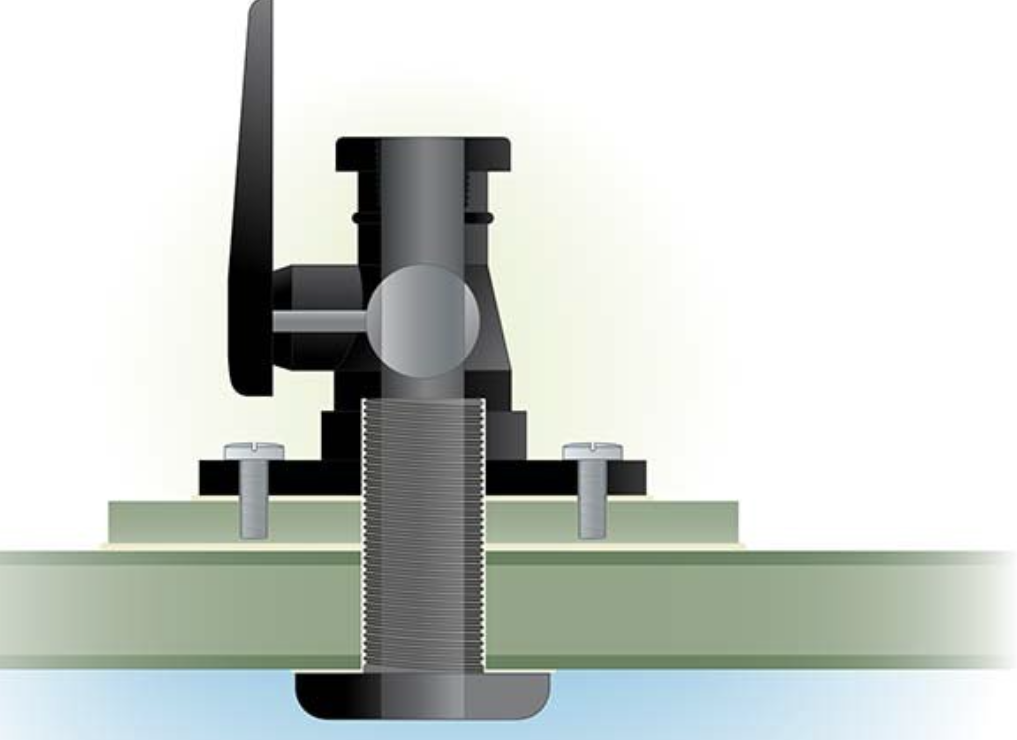

Cooling System Differences

Automotive engines use pressurized closed-loop cooling with a radiator. Marine engines use one of two systems:

Raw-water cooling – Draws water directly from the lake or ocean, pumps it through the block, and dumps it out the exhaust. The pump, impeller, and all internal passages must resist corrosion. Automotive water pumps use steel impellers and housings that'll corrode in days in saltwater. Get marine-grade parts like water pumps and impellers from our cooling system collection.

Closed cooling (heat exchanger) – Uses a freshwater loop inside the engine (like a car) but exchanges heat to raw water through a separate heat exchanger. The raw-water side still needs marine-rated components.

Either way, an automotive water pump, thermostat, or gasket set isn't built for saltwater or the silt and debris in raw water. I've seen automotive thermostats seize solid in one season from salt buildup.

ABYC and USCG Compliance

The American Boat & Yacht Council sets the technical standards most surveyors and insurers use to evaluate a boat. Key standards include:

- ABYC E-11: Electrical systems—specifies ignition protection, wire types, circuit protection, and grounding

- ABYC E-1500: Fuel system standards for gasoline engines

- 33 CFR 183.410 (USCG): Federal requirement for ignition protection on gasoline engines

If your boat doesn't meet these, you're not just risking safety—you're risking your insurance payout. After a fire or explosion, the first thing a marine surveyor does is check for non-compliant parts. If they find an automotive alternator or a non-marine fuel pump, the claim gets denied. I've watched it happen three times in my career, and every time the boat owner was shocked that "it worked fine for months" wasn't a defense.

Cost Reality Check

Here's the real cost breakdown:

Scenario 1: Automotive alternator

- Purchase price: $80

- Lifespan in marine environment: 6–18 months (corrosion, moisture, duty cycle)

- Risk of fire: moderate to high

- Insurance claim denial if failure causes incident: $0 payout on a $30,000–$100,000+ loss

Scenario 2: Marine-rated alternator

- Purchase price: $250–$400

- Lifespan: 5–10+ years with proper maintenance

- Risk of fire: minimal (designed for the application)

- Insurance and survey compliance: full

You're not saving money. You're deferring a bigger bill and adding catastrophic risk.

What About Diesel Engines?

Diesel engines are a different story. Because diesel fuel has a much higher flash point than gasoline, the ignition-protection requirements don't apply the same way. You'll still see marinized diesels with different cooling systems, corrosion-resistant materials, and upgraded electrical components, but the explosion risk from a non-marine alternator is drastically lower.

That said, corrosion still kills automotive parts fast in a marine environment. Even on a diesel, you want marine-rated components for longevity.

Myth: "I'll Just Leave the Hatch Open"

I've heard this one a hundred times: "It's fine, I run with the engine hatch open so vapors vent."

Doesn't matter. Gasoline vapors are heavier than air—they sink and collect in the bilge even with the hatch wide open. ABYC and USCG standards assume an enclosed space because that's how boats are built. Ventilation helps, but it's not a substitute for ignition-protected components.

Also, if you're underway and water comes over the stern or you hit rough conditions, that hatch is getting closed fast. Now you've got an automotive starter in an enclosed space with fuel vapors. One crank and you're done.

Real Parts Quality: OEM vs. Aftermarket

Let's talk about parts sourcing, because this comes up constantly.

OEM (Original Equipment Manufacturer) parts are good. They're built to spec, they fit right, and they're compliant. But you're paying a 40–60% markup for the logo on the box and the dealer's overhead.

Cheap offshore aftermarket is a gamble. I've seen $30 impeller kits with rubber so hard it won't seal, fuel pumps that fail in a week, and starters with non-sealed housings sold as "marine" when they're just painted automotive units.

High-quality aftermarket (like what we stock at JLM Marine) gives you OEM-equivalent parts without the dealer markup. Many of these parts come from the same factories that produce for the OEM brands—they just run extra capacity for the aftermarket. You get the same materials, the same tolerances, and the same compliance stamps (SAE J1171, ISO 8846, ABYC) at a fair price. We've shipped these worldwide, and the failure rate is on par with OEM because the engineering is identical.

The key is verify compliance. If a part is labeled for marine ignition protection, it'll have an SAE J1171 or ISO 8846 stamp, or explicit USCG or ABYC compliance language. If it doesn't, walk away.

Insurance and Survey Implications

Marine surveyors know what to look for. During a pre-purchase survey or an insurance claim investigation, they'll check:

- Starter and alternator for ignition-protection labels

- Fuel system routing and component compliance

- Electrical system for ABYC E-11 compliance

- Evidence of non-marine parts or improper modifications

If they find automotive components in critical areas, expect one of these outcomes:

- Pre-purchase survey: Boat fails, buyer walks or demands a price reduction to cover re-fit costs

- Insurance underwriting: Higher premiums, exclusions, or outright denial of coverage

- Post-incident claim: Claim denied if the automotive part contributed to the failure

I've seen buyers lose $15,000 in negotiating leverage because a surveyor found an automotive alternator and flagged the entire electrical system as non-compliant.

What If You Already Have Automotive Parts Installed?

Check your engine now. Here's how to identify non-marine components:

Starters and alternators – Look for an "SAE J1171," "Marine," or "Ignition Protected" stamp on the housing. If it says "Delco," "Motorcraft," or another automotive brand with no marine designation, it's likely automotive.

Fuel pumps – Marine pumps will be labeled with USCG or ABYC compliance. Automotive pumps usually aren't. Browse authentic marine fuel pumps to replace them.

Wiring and switches – Marine-rated switches and wire will have specific insulation types and ignition-protection ratings. If your bilge pump switch or blower switch is a generic automotive toggle, replace it.

If you find automotive parts, replace them immediately. It's not worth the risk. Budget $500–$1,500 depending on how many components need swapping, but that's cheap compared to a total loss.

When You Might Marinize an Automotive Engine

There are cases where marinizing a car engine makes sense:

- Restoration projects where the original marine engine is unavailable or prohibitively expensive

- High-performance builds where a specific automotive block offers better performance potential

- Diesel swaps where ignition-protection requirements are relaxed

But even then, you need:

- A machine shop experienced in marine conversions

- Complete replacement of all ignition, fuel, and cooling components with marine-rated equivalents

- Documentation and labeling for surveyors and insurers

- A realistic budget—marinization isn't cheap, often $3,000–$8,000+ depending on the engine

If you're not prepared to do it right, buy a factory marine engine or a professionally remanufactured marine long block from a reputable supplier.

rpm and Load Differences

Boat engines operate differently than car engines. A car engine spends most of its life at partial throttle, coasting, idling. A boat engine runs at 70–80% throttle almost constantly when underway—it's effectively climbing a steep hill the entire time.

This changes:

- Camshaft profile – Marine cams have less aggressive overlap to prevent exhaust reversion (where water gets sucked back into the engine during deceleration)

- Bearing clearances – Marine engines often use slightly tighter tolerances to handle continuous load

- Cooling demand – Continuous high-rpm operation generates more heat, requiring more robust cooling, which you can maintain with parts from the cooling system collection

An automotive cam in a marine engine might run fine at idle and low speed, but under load it'll cause rough running, potential water ingestion, and long-term damage.

Emergency Scenario: Can I Use an Auto Part Just to Get Home?

No. Even for a short trip, using a non-ignition-protected part in a gasoline engine compartment is illegal under USCG regulations and unsafe. Fuel vapors don't care if you're only running for ten minutes. One spark is all it takes.

If you're stranded and need a part, call a marine towing service (TowBoatU.S., Sea Tow) or have the correct part shipped overnight. Don't jury-rig an automotive component as a "temporary fix." I've seen "temporary" last for months, then end in a fire.

Where to Source Correct Marine Parts

When you need a replacement part:

- Get the engine serial number – This is critical for cross-referencing the correct part. Guidance on serial numbers can be found in our Mercury Serial Number Guide.

- Verify marine compliance – Check for SAE J1171, ISO 8846, ABYC, or USCG language on the part or in the product description.

- Use a reputable supplier – OEM from a dealer is safe but expensive. High-quality aftermarket from a marine-focused supplier like JLM Marine gives you compliance and quality without the markup. We ship factory-direct worldwide, and every part we stock meets or exceeds OEM specs with proper certifications. Our boat accessories collection includes many compliant parts for your vessel.

Avoid generic online marketplaces unless you can verify compliance yourself. A listing that says "fits marine application" isn't the same as "ignition protected per SAE J1171."

Next Steps If Your Engine Is Blown

If you're facing a dead engine and considering an automotive swap to save money:

- Diagnose the failure – Often a "blown" engine is repairable. Get a qualified marine mechanic to assess it.

- Price a remanufactured marine engine – Companies like Jasper, Remanufactured Products Inc., and others offer fully marinized long blocks with warranties. Compare that cost to a DIY automotive swap plus marinization.

- Check your insurance – Some policies cover engine replacement or mechanical breakdown.

- Get multiple quotes – A rebuilt marine engine might cost $4,000–$8,000 installed, but a bad DIY swap could cost you the entire boat.

Don't let short-term budget pressure push you into a decision that creates long-term risk.

FAQ

Can I use an automotive battery in my boat?

Yes, if it's a starting battery and meets the correct specs (CCA, size, terminal type). Marine batteries are often built with more vibration resistance and better case sealing, but a good automotive battery will work for starting. For deep-cycle applications (house banks, trolling motors), use true deep-cycle or marine dual-purpose batteries.

Can I use automotive oil in my boat engine?

Depends on the engine. Many marine engines spec the same oil as their automotive counterparts (e.g., 10W-30, 15W-40). Check your manual. Some marine engines require specific marine oil due to different additive packages for corrosion protection or emissions compliance.

Can I use an automotive spark plug?

Often yes, if the heat range and thread reach are identical and the plug is used in a marine-rated ignition system. Verify the cross-reference in your engine manual. The plug itself isn't the ignition risk—the distributor, coil, and wiring are.

Can I use automotive exhaust manifolds?

No. Marine exhaust manifolds are built from corrosion-resistant cast iron or use special coatings. They're also configured for water injection (in many systems) to cool exhaust gases before they exit. Automotive manifolds will corrode rapidly and don't support marine exhaust cooling.

What if I'm running in freshwater only?

Corrosion is slower, but ignition-protection requirements don't change. USCG and ABYC standards apply to all gasoline-powered boats, regardless of water type. Freshwater reduces the rate of corrosion on non-marine parts but does nothing for explosion risk.

Check your alternator and starter this week for the SAE J1171 stamp. If you don't see it, you're running illegal and unsafe components—schedule replacements before the next trip. For trusted parts and expert support, visit the JLM Marine homepage to explore our full range of quality marine components.

Leave a comment

Please note, comments need to be approved before they are published.