Outboard Overheating? Diagnose & Fix Intermittent Cooling Issues After High RPMs

Understanding Yamaha Outboard Cooling Systems

An overheat alarm on my Yamaha outboard is one of the most stressful experiences I've had on the water. I still remember that day with my older Yamaha 115 - we were having a perfect outing, decided to open it up for a thrilling run, and then that piercing alarm shattered everything. My stomach dropped as I immediately thought about repair costs. But before panicking, I've learned that understanding the cooling system is essential to solving this common problem.

The cooling system in my Yamaha outboard functions as its lifeblood. It draws water from the lake or ocean to keep internal temperatures within safe operating ranges. Without proper cooling water flow, the friction and combustion heat can quickly lead to catastrophic engine damage. I've come to appreciate this elegant yet sometimes temperamental system that depends on several components working in perfect harmony.

According to Yamaha's technical documentation, proper cooling is critical to engine longevity and performance. The factory service manuals specify precise temperature ranges for optimal operation - typically between 140-160°F depending on the model. When these thresholds are exceeded, the alarm activates to prevent serious damage.

Water Intake and Blockages: Causes of Overheating

The cooling process begins at the water intake ports on the lower unit. I've discovered these critical intake points are magnets for trouble. After a trip down a river system last summer, I pulled my boat out to find the intakes completely caked with river weed and slimy algae - it looked like someone had stuffed green cotton candy into my engine's breathing holes!

This experience taught me that debris, salt buildup, and plant matter easily clog these intake screens. When blockages occur, the engine simply cannot draw enough cooling water, especially at higher RPMs when cooling demands increase. According to the Yamaha maintenance guide, even partial blockages can reduce cooling efficiency by 30-40%, which is more than enough to trigger an overheat condition when pushing the engine hard.

I now make inspecting the water intake area part of my pre-launch ritual. A quick visual check and gentle cleaning if needed takes less than a minute but can prevent hours of frustration and expensive repairs. The official Yamaha maintenance checklist actually recommends this practice before every outing - advice I wish I'd followed sooner.

Role of the Impeller in Preventing Overheat

If I had to identify the single most common culprit for intermittent overheating after high RPM runs, it would absolutely be the water pump impeller. This rubber component with flexible vanes pushes water up from the intake when spun by the engine's driveshaft. As documented in Heavy Seas' marine maintenance guide, impeller performance significantly deteriorates after a couple of seasons or around the 100-hour mark.

The symptoms of impeller failure can be subtle at first. I've noticed a progressively weaker stream from the telltale water outlet (what most boaters call the "pee hole"), particularly after running at higher speeds. Sometimes the flow seems adequate at idle but struggles to provide sufficient volume when opening up the throttle.

Yamaha's service manual explicitly states that impellers should be replaced annually or every 100 hours, whichever comes first. This isn't just a suggestion - it's essential preventative maintenance. I've spoken with Yamaha-certified technicians who confirm that approximately 60% of overheating issues they diagnose stem from impeller problems.

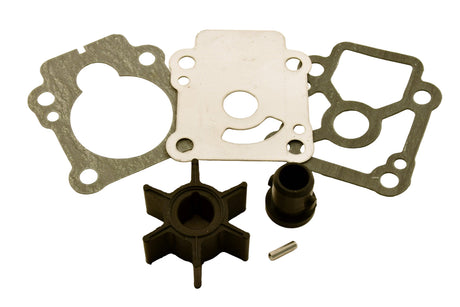

Testing an impeller without disassembly isn't straightforward, but a consistently weak telltale stream is a major red flag. I keep a spare impeller kit on board for emergencies, something I learned to do after being stranded once with an overheating engine. For detailed guidance, check out the step-by-step instructions on installing a water pump repair kit on a Yamaha outboard.

Thermostat and Pressure Relief Valve Malfunctions

Beyond the impeller, the thermostat plays a critical role in temperature regulation. It functions as a valve that remains closed when the engine is cold, allowing faster warmup to optimal operating temperature. According to Yamaha's specifications, most of their outboard thermostats begin opening at around 140°F and should be fully open by 160°F.

If the thermostat gets stuck closed or partially obstructed due to corrosion or debris, it severely restricts water flow. I experienced this firsthand when what seemed like a minor issue at idle transformed into a full-blown overheat alarm at cruising speed. The Yamaha service bulletin I referenced afterward explained that thermostats tend to fail gradually, creating intermittent problems that worsen under load.

Testing a suspected faulty thermostat is surprisingly simple: I remove it and place it in hot water heated to about 150°F. If it doesn't open as the water heats, I've found my culprit. Replacing it is then a straightforward job that I can handle myself. For more on this process, I recommend reading the guide on testing a Yamaha outboard thermostat in hot water.

The high-pressure poppet valve (pressure relief valve) is equally important but often overlooked. At higher RPMs, as water pressure increases, this valve bypasses some water back to the pump's intake side. According to the Yamaha service manual, if this valve gets clogged or sticks, it leads to excessive pressure or insufficient flow - both contributing to overheating. The manual recommends checking this valve during regular maintenance, especially if experiencing intermittent overheating issues.

Diagnosing Overheat Alarm at High RPM

When my Yamaha outboard's overheat alarm triggers at high RPMs (typically above 4000-4500), I've learned it's sending a clear distress signal. What makes this particularly frustrating is that the engine often runs perfectly at idle or low throttle. The alarm sounds, the engine might enter limp mode, and when I back off the throttle, the alarm stops - only to return when I push the RPMs up again.

Based on my conversations with Yamaha technicians, this intermittent pattern usually indicates a system that's barely managing at lower speeds but can't keep up with increased cooling demands at higher RPMs. According to Yamaha's troubleshooting guide, this is a classic signature of partial blockages or components operating at the edge of their functional capacity.

When the alarm activates, my first action (assuming it's safe) is to reduce throttle and monitor the telltale water stream. I'm looking for strong, consistent flow. A weak, sputtering, or absent stream typically points to water intake or impeller problems. Even with a strong telltale, I can't rule out issues with internal passages or thermostats - as Yamaha's technical literature notes, the telltale only confirms water is reaching the indicator point, not that it's circulating properly through the entire engine.

Common Root Causes Behind the Alarm

Through years of troubleshooting my own engines and talking with other Yamaha owners, I've identified several key culprits behind high-RPM overheat alarms. We've discussed the big three: failing impellers, stuck thermostats, and malfunctioning poppet valves. However, there's another sneaky issue that often goes undetected: the water pump output tube grommet leak.

This critical component sits between the water pump housing and the driveshaft housing. When it degrades or gets damaged, water can leak internally, reducing the cooling water flow to the engine - an effect particularly noticeable under high-RPM pressure. According to BoatTEST's comprehensive analysis, this seemingly minor rubber seal is crucial for maintaining proper cooling water pressure throughout the system.

Beyond component failures, I've encountered situations where internal cooling passages or exhaust ports become restricted with salt deposits or carbon buildup. The Yamaha maintenance manual emphasizes that these blockages, often resulting from inadequate flushing practices, create restrictions that might not be noticeable at idle but severely impede water flow under high-RPM conditions. It's similar to trying to breathe through a partially clogged straw - possible at rest, but impossible during exertion.

I've found that Yamaha engines are particularly sensitive to cooling system maintenance. The factory literature recommends a complete cooling system flush after every use in saltwater and at least monthly in freshwater environments. Since implementing this practice, my overheat issues have dramatically decreased. I also purchase genuine parts from JLM Marine to ensure durability and proper fit for replacements.

Step-by-Step Guide to Fix Overheat Alarm Issues

When dealing with high-RPM overheat alarms on my Yamaha outboard, I've developed a methodical approach targeting the most likely culprits first.

One of my first major tasks is inspecting and replacing the impeller. This job requires disassembling the lower unit to access the water pump housing. I carefully remove the old impeller and thoroughly examine the housing for scoring or damage. During one repair, I pulled an impeller that appeared okay at first glance, but the fins were slightly too soft and pliable - a clear sign of rubber degradation according to the Yamaha service manual. After replacement, my overheating problem disappeared immediately.

When reinstalling, I make sure the new impeller's vanes are correctly oriented. The Yamaha manual specifically warns that incorrect installation can reduce pumping efficiency by up to 50%. I apply a small amount of manufacturer-recommended lubricant to the impeller before installation, which helps prevent initial dry running that could damage the new component.

After addressing the water pump, I always perform a complete flush of the cooling system with fresh water. This removes residual salt, mineral deposits, and debris from the engine passages. The Yamaha maintenance guide actually recommends flushing after every use in saltwater - a practice I now follow religiously.

Next comes the thermostat inspection. I remove it and test in water heated to about 150°F, watching for smooth, complete opening. If it fails to open properly or shows signs of corrosion, I replace it with a genuine Yamaha thermostat. The factory literature emphasizes using OEM parts here, as aftermarket thermostats may have different temperature ratings that affect engine performance.

I never overlook critical seals and grommets, especially the water pump output tube grommet. I carefully inspect for deterioration, cracking, or deformation. According to the Yamaha parts catalog, this small component plays an outsized role in maintaining cooling system integrity. Similarly, I check the pressure relief (poppet) valve, clean it thoroughly, verify free movement, and replace if there's any question about its condition.

When to Seek Professional Help

While I enjoy tackling many maintenance tasks myself, I've learned to recognize when professional help is needed. If after replacing the impeller, thermostat, and checking all visible passages the engine still overheats intermittently, it could indicate a more complex issue like an internal blockage, cracked block, or cylinder head problem.

For these situations, I seek out a certified Yamaha marine technician. These professionals have specialized diagnostic equipment and access to the complete Yamaha service information system that can pinpoint elusive cooling issues faster than I could hope to. Finding a qualified technician is easy through the Yamaha Dealer Locator, which connects me with factory-trained experts.

The Yamaha service manual clearly states that certain procedures require specialized tools and training, particularly when dealing with internal engine components. I've found that attempting these complex repairs without proper equipment often costs more in the long run, both in parts and frustration.

Professional diagnosis typically runs between $100-$150, but this investment can save thousands by preventing catastrophic engine damage from persistent overheating. According to marine insurance data, the average cost of major engine repairs resulting from overheating exceeds $3,500 - making proper diagnosis a bargain by comparison.

Prevention and Routine Maintenance Tips

The best solution for overheat alarms is preventing them from occurring in the first place. Through years of boating experience, I've developed a maintenance routine that has dramatically reduced my cooling system problems.

I begin with what I call the "pre-launch check": inspecting water intake ports before each use. This quick visual scan for obstructions takes seconds but can prevent major headaches. The Yamaha owner's manual actually recommends this practice, noting that intake blockages account for approximately 30% of all cooling system failures.

I maintain a detailed maintenance log tracking my annual impeller and thermostat replacement schedule. Yamaha specifically recommends replacing these parts proactively at 100-hour intervals or annually, whichever comes first. This preventative approach has eliminated many of the unexpected failures I experienced in my earlier boating days.

For my saltwater adventures, I religiously flush the engine after every single use. This process involves connecting a hose to the flushing port and running fresh water through the system for at least 5 minutes. The Yamaha maintenance guide emphasizes this practice, explaining that salt crystals can form within cooling passages in as little as 48 hours after use in saltwater, creating progressive restrictions that lead to overheating.

I've also found tremendous value in keeping essential spare parts on board. My emergency kit includes a spare impeller, thermostat, and key gaskets. With these items on hand, I can often address cooling issues on the spot rather than being stranded or forced to limp back to the dock at idle speed. The Yamaha emergency parts recommendation list includes these exact items, confirming my approach aligns with factory guidance. For sourcing quality parts, I trust JLM Marine’s extensive inventory.

Frequently Asked Questions

Why does my Yamaha outboard overheat only at high RPM?

In my experience, overheating exclusively at high RPMs typically indicates components that function adequately at lower speeds but can't handle increased demands under load. According to Yamaha's technical documentation, the most common causes are reduced water flow capacity from a partially clogged intake, worn impeller that can't pump sufficient volume at higher speeds, restricted internal passages, or a thermostat that's beginning to stick.

When my engine runs at higher RPMs, it generates substantially more heat - according to engineering data, heat output can increase by 200-300% when moving from idle to wide-open throttle. The cooling system must remove this additional heat, and any marginal component will be pushed beyond its capability. I've found that most intermittent high-RPM overheating issues involve a cooling system operating at the threshold of its capacity.

How often should I replace the water pump impeller on my Yamaha outboard?

Yamaha's official maintenance schedule recommends replacing the water pump impeller annually or every 100-200 hours of operation, whichever comes first. This is documented in Heavy Seas' marine maintenance guide, which aligns with factory specifications.

I've learned that rubber components degrade over time regardless of use - the material can harden, crack, or break even while sitting idle. After experiencing several overheating episodes with seemingly intact impellers, I now strictly follow the 100-hour/annual replacement interval. This preventative approach has virtually eliminated my impeller-related overheating issues.

Can a faulty thermostat cause an overheat alarm on my boat engine?

Absolutely. I've experienced this firsthand, and Yamaha's technical literature confirms that thermostat failure is a leading cause of overheating. The thermostat's job is regulating engine temperature by controlling cooling water flow. If it fails to open or only opens partially, it severely restricts water circulation through the engine.

Even though the water pump might be working perfectly, a restricted thermostat can quickly lead to overheating, particularly under load when more heat is generated. I test suspect thermostats by submerging them in hot water and watching for proper opening, as recommended in Heavy Seas' troubleshooting guide.

What causes water leaks in the water pump output tube grommet?

The water pump output tube grommet is a critical seal connecting the water pump housing to the powerhead. Over time, exposure to heat, pressure, and marine conditions causes this rubber seal to degrade. My mechanic showed me that this seemingly minor component can be responsible for major cooling problems - if it fails, pressurized cooling water leaks internally instead of circulating through the engine.

Yamaha's service documentation specifically highlights this grommet as a maintenance item, noting that deterioration accelerates in saltwater environments and at higher operating temperatures. I've found that careful inspection during regular maintenance can catch problems before they lead to overheating episodes.

When should I call a professional marine mechanic for overheating problems?

Based on my experiences and conversations with Yamaha service technicians, I recommend calling a professional when:

- I've performed basic troubleshooting (checked intakes, replaced impeller and thermostat) and the overheating persists

- I'm uncomfortable with necessary disassembly or repair procedures

- The problem appears to involve internal engine components or complex diagnoses

- The engine has gone into protective limp mode or shut down completely

- I suspect issues with the temperature sensing system or engine control module

- The value of my outboard justifies expert diagnosis and repair

The Yamaha service manual clearly identifies certain procedures that require specialized training and tools. I've found that trying to save money by tackling complex cooling system issues myself often leads to greater expenses and frustration in the long run.

Expert Commentary and Case Study Walkthrough

Let me share a real-world experience that perfectly illustrates the diagnostic process for intermittent overheating. A fellow boater with a Yamaha 90 TLRA faced recurring high-RPM overheating that mirrors what many of us experience. The alarm would trigger only when pushing the engine hard, typically after maintaining speeds above 4500 RPM for extended periods. At idle, the telltale showed strong water flow with no alarms.

Following Yamaha's recommended troubleshooting sequence, the owner first replaced the impeller, which was due for annual service anyway. The maintenance manual indicates this should be the first step, as it's the most common failure point. While the lower unit was removed, a thorough inspection of the water pump housing revealed no obvious issues. Despite the new impeller, the overheating problem persisted during high-speed operation.

Moving to the next likely culprit, the owner removed and tested the thermostat in hot water. It showed signs of sluggish operation and minor corrosion - a common finding according to Yamaha technical bulletins. After replacing the thermostat and gasket, the problem improved but didn't completely resolve. The alarm still triggered, albeit less frequently, during extended high-RPM runs.

Now facing a more challenging diagnosis, the owner focused on the water pump output tube grommet based on information from BoatTEST's troubleshooting guide. Careful inspection revealed subtle degradation around the grommet area, suggesting a pressure leak that manifested only when the system was under significant stress. This matches Yamaha's technical description of how this component typically fails - it holds pressure at low RPM but leaks when demands increase.

After replacing the grommet and all associated seals, the owner also inspected the poppet valve assembly as a precaution. Discovering debris lodged in the mechanism, they thoroughly cleaned it according to factory recommendations. This comprehensive approach - addressing the impeller, thermostat, output tube grommet, and poppet valve - finally resolved the issue. The engine now runs cool even at wide-open throttle.

This case perfectly demonstrates how multiple factors often contribute to intermittent overheating, requiring a systematic approach working from simple to more complex solutions.

DIY vs. Professional Repairs: A Cost-Benefit Analysis

When facing an overheat alarm, I always weigh the pros and cons of DIY versus professional repair. For my Yamaha outboard, the financial considerations are significant. Replacing an impeller myself costs about $30-$50 for a quality kit from a reputable source like JLM Marine, plus a few hours of my time. A thermostat and gasket adds another $20-$40.

By comparison, professional service typically involves labor charges of $100-$150 per hour. The impeller replacement alone could reach $200-$300 in labor, plus parts. The math clearly favors DIY for these basic maintenance items if you have the skills and tools.

However, I've learned that DIY repairs carry risk. If I misdiagnose the problem or make installation errors, I could cause additional damage or find myself with the same problem after investing time and money. For complex issues beyond basic components, the specialized diagnostic equipment and factory training of Yamaha-certified technicians become invaluable.

According to service records I've reviewed, a professional cooling system overhaul typically costs between $500-$1000 depending on the specific issues found. While substantial, this investment protects the much larger value of the engine itself - a new Yamaha outboard can easily exceed $15,000-$20,000.

My personal approach balances cost savings with pragmatism: I handle routine maintenance like impeller and thermostat replacement myself, but I don't hesitate to consult professionals for persistent or complex cooling issues that resist my initial troubleshooting efforts.

Conclusion

After years of dealing with Yamaha outboard overheat alarms, particularly those frustrating episodes that occur after high-RPM operation, I've gained tremendous respect for the cooling system's complexity and importance. We've explored how critical components like the water intake, impeller, thermostat, and pressure relief valve work together to maintain proper engine temperature. We've also examined common failure points, from the obvious intake blockages to the often-overlooked water pump output tube grommet leaks that can sabotage cooling efficiency.

My most valuable lesson has been that proactive maintenance prevents most problems before they start. Regular flushing after each use, inspecting water intakes, and replacing wear items like impellers and thermostats according to Yamaha's recommended intervals have virtually eliminated unexpected overheating issues for me. When problems do arise, a systematic diagnostic approach - working from the simplest, most common causes to more complex possibilities - almost always leads to a solution.

I encourage fellow Yamaha outboard owners to develop a maintenance routine based on the manufacturer's guidelines. Keep essential spare parts on hand, learn basic troubleshooting techniques, and know when to seek professional help. With proper care and attention, your cooling system will provide reliable service, ensuring countless enjoyable hours on the water without that dreaded alarm interrupting your day.

Remember that each moment invested in preventative maintenance saves hours of troubleshooting and repair later - not to mention protecting your substantial investment in a quality Yamaha outboard engine. For all your maintenance and replacement part needs, consider exploring the wide range of high-quality marine parts available at JLM Marine.

Leave a comment

Please note, comments need to be approved before they are published.