Long Shaft vs. Short Shaft Outboards: Choosing the Right Length

- Measuring Your Transom Height

- Short Shaft Outboards (15 Inches)

- Long Shaft Outboards (20 Inches)

- Extra-Long and Ultra-Long Shafts (25 and 30 Inches)

- Symptoms of the Wrong Shaft Length

- Matching Shaft to Hull and Water Conditions

- Jack Plates and Shaft Adapters

- Specific Recommendations by Transom Height

- What Not to Do

- Performance and Fuel Efficiency

- Electric Outboards and Non-Standard Lengths

- The JLM Marine Approach

Measuring Your Transom Height

Grab a metal tape measure. Put one end at the top center of the transom where the motor bracket will clamp, then measure straight down to the bottom of the hull at the keel. That's your transom height. Write it down because this number dictates your shaft length.

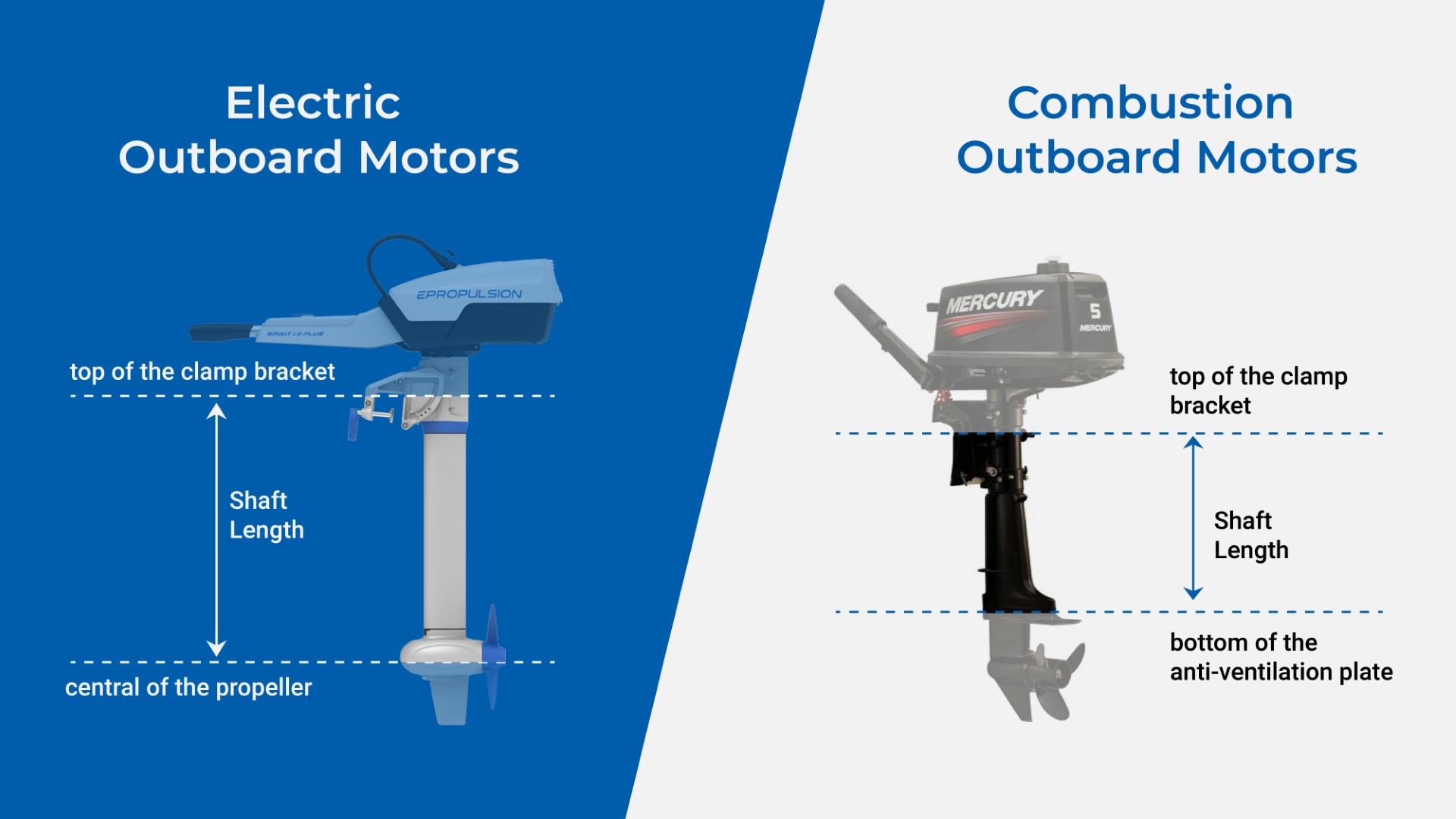

The shaft length on an outboard is measured from the top of the mounting bracket down to the cavitation plate—that flat metal plate just above the prop. Match your transom measurement to the motor's shaft length so the cavitation plate sits level with or just below the hull bottom. When it's right, the prop stays submerged and bites clean water. When it's wrong, you get ventilation, drag, or both.

Short Shaft Outboards (15 Inches)

Short shafts run about 15 inches and pair with transoms measuring 15 to 17 inches. You'll find them on small jon boats, inflatable tenders, dinghies, and lightweight skiffs. They're lighter, easier to mount and dismount, and easier to throw in a truck bed. In very shallow water—marsh creeks, backwater rivers, skinny ponds—a short shaft keeps the prop higher and less likely to catch mud or hit stumps.

The flip side: in any kind of chop, the prop breaks the surface. You'll hear the engine scream as it sucks air, RPM spikes without a speed increase, and your fuel burn goes through the roof. We've seen guys running short shafts on bigger water lose thrust mid-wave and get tossed around. If you run anything beyond flat calm, a short shaft on a low transom is a gamble.

Check your cooling water intake ports—on a short shaft they sit lower on the gearcase. If the prop ventilates and lifts the lower unit, those intakes can pull air instead of water, and your engine will overheat fast. For maintenance tips to keep your engine cooling system in top shape, see our guide on Outboard Overheating 101: Quick Checks to Prevent Damage.

Long Shaft Outboards (20 Inches)

Long shafts measure around 20 inches and match transoms in the 20-inch range. These are standard on mid-sized fishing boats, family runabouts, larger inflatables, and many sailboats. The extra length keeps the prop deeper in the water, so in waves or chop, you maintain consistent thrust. The prop stays submerged, the cavitation plate stays below the surface, and you don't get that sudden loss of power that kills your steering control.

Long shafts also give you a smoother ride because the prop isn't porpoising in and out of the water. Trim and handling improve, especially when docking or running in following seas. We've had customers running the North Sea and the Great Lakes swear by long shafts—when the water gets ugly, that extra depth makes all the difference.

The trade-off: in shallow water, you're more likely to hit bottom. The lower unit sits deeper, so you pick up more drag, which can shave a couple mph off your top speed and hurt fuel efficiency slightly. But for most recreational boaters on larger lakes or coastal water, the stability and control gains outweigh the drag penalty. For tips on improving trim and control, consider our article on Do Hydrofoils Really Improve Outboard Performance?.

Extra-Long and Ultra-Long Shafts (25 and 30 Inches)

Transoms measuring 25 inches call for extra-long shafts around 25 inches. You'll see these on offshore center consoles, blue-water sailboats, and high-freeboard hulls where the transom sits well above the waterline. Ultra-long shafts (30 inches) are less common but show up on custom offshore builds and displacement sailboats that need the prop deep for low-speed maneuvering under power.

If you're running a sailboat with a high cockpit or a center console designed for big swells, measure carefully. A standard long shaft won't cut it—you'll ventilate in waves and lose steerage when you need it most. We've guided customers restoring older Whalers and sailboats who needed jack plates or custom mounts to adapt modern motors to non-standard transoms. To better understand how jack plates help in such situations, review our blog on Installing a Jack Plate: Benefits for Shallow Water Boating.

Symptoms of the Wrong Shaft Length

Too short: RPM spikes without speed increase. Water spits weakly from the telltale at idle but doesn't improve much with throttle. Engine sounds like it's screaming in waves. Stern feels unstable or loose in chop. If you see foam or turbulence around the prop in anything but flat calm, your shaft is too short for the transom.

Too long: Sluggish acceleration. Top speed lower than spec. Steering feels heavy or unresponsive. Exhaust relief ports stay underwater even at speed, which can load the engine. If you're constantly trimming the motor up to reduce drag or if the lower unit is scraping bottom in water that should be deep enough, your shaft is too long.

Matching Shaft to Hull and Water Conditions

A deep-V hull sits higher in the water than a flat-bottom skiff, so two boats with identical transom heights might need different setups depending on hull shape. Catamarans or tunnel hulls can throw this off completely—the central tunnel changes water flow around the prop, and you often need to adjust shaft length or use a jack plate to get the cavitation plate in the right spot.

Consider where you actually run the boat. If you trailer to different lakes and sometimes hit rough water, lean toward the longer shaft even if it's borderline. If you're locked into shallow backwaters and never see waves, the short shaft makes more sense. Don't buy based on what looks cool or what's on sale—buy based on your transom measurement and your worst-case water conditions.

Jack Plates and Shaft Adapters

Jack plates bolt between the transom and the motor and allow you to raise or lower the entire outboard. A standard manual jack plate gives you about 3 to 5 inches of vertical adjustment, which can turn a borderline setup into a perfect one. Hydraulic jack plates offer more range and let you adjust on the fly, but they cost more and add weight.

We've used jack plates to fit a 20-inch motor onto an 18-inch transom or to lift a long shaft slightly on a boat that runs skinny water part-time. They're invaluable for custom builds or re-powers where the original transom height doesn't line up with modern motor dimensions.

Shaft conversion kits let you swap the driveshaft and gearcase to change a short shaft into a long shaft or vice versa. You're replacing the lower unit internals, the driveshaft, the water tube, and the shift rod. It's precise work. If the alignment is off by a fraction, you'll have vibration, shifting problems, or water pump failure. For maintenance on water pumps and cooling systems to avoid such issues, see Water Pump Repair Kit vs. Impeller Only: What Does Your Outboard Need? and our Cooling System parts collection.

The cost of a conversion kit plus labor can approach the price of a used motor with the correct shaft length, so run the numbers before committing.

When does a conversion make sense? When you found a smoking deal on a used motor with the wrong shaft and the cost to convert is still lower than buying the right motor outright. Or when the correct-length motor is unavailable or backordered for months. Otherwise, buying the right shaft length from the start saves headaches.

Specific Recommendations by Transom Height

| Transom Height | Shaft Type | Shaft Length | Typical Boats |

|---|---|---|---|

| 15–17 inches | Short shaft | ~15 inches | Jon boats, dinghies, small inflatables, car-topper skiffs |

| 19–22 inches | Long shaft | ~20 inches | Mid-sized fishing boats, runabouts, larger inflatables, many sailboats |

| 24–26 inches | Extra-long shaft | ~25 inches | Offshore center consoles, high-transom sailboats, displacement hulls |

| 28–30 inches | Ultra-long shaft | ~30 inches | Blue-water sailboats, custom offshore builds |

If your transom measures 17 to 18 inches—right in the gap—go with the long shaft and use a small jack plate or setback bracket if you need fine-tuning. It's safer to have the prop slightly deeper and adjust up than to run a short shaft that ventilates in waves.

What Not to Do

Don't cut down your transom to fit a short shaft motor. We've seen guys hack 2 inches off the transom with a circular saw to mount a motor they got cheap. The structural integrity is gone, the boat takes on water in following seas, and you've destroyed resale value.

Don't use wood blocks or homemade spacers to raise a motor. The vibration will crack the wood, the bolts will loosen, and the motor will shift or fall off. If you need height adjustment, buy a proper jack plate or setback bracket with a manufacturer's load rating.

Don't assume "close enough" is fine. A 1-inch difference in effective prop depth changes thrust, handling, and fuel burn more than you'd think. Measure twice, order once.

Performance and Fuel Efficiency

Fuel efficiency depends on the cavitation plate being in the sweet spot. If a short shaft ventilates and over-revs in rough water, you'll burn more fuel than a correctly matched long shaft, even though the long shaft has slightly more wetted surface. The drag from a too-long shaft is measurable—maybe a couple mph off top speed—but for most recreational use, the stability and consistent thrust matter more.

Ventilation isn't just annoying; it's a safety issue. Loss of thrust at the wrong moment can mean losing steerage near a dock, in a channel, or in heavy boat traffic. A long shaft that keeps the prop buried gives you predictable propulsion when you need it.

Electric Outboards and Non-Standard Lengths

Electric outboards often use different dimensions than combustion motors. A "short" electric might be 25 inches, and a "long" might be 30 inches. Don't assume the label matches the measurement—check the manufacturer's spec sheet and measure your transom the same way: top center to keel.

If you're switching from a combustion motor to electric or vice versa, verify the shaft length from the chart, not the name. We've seen customers order a "short shaft" electric and get a motor that's 10 inches longer than their old gas short shaft.

The JLM Marine Approach

We manufacture and supply marine parts direct from the factory, which means you skip the dealership markup and get the same quality you'd pay double for elsewhere. Whether you need a jack plate to adapt a non-standard transom, a shaft conversion kit, or just the right length motor from the start, we can ship it to your dock anywhere in the world. Browse our full range of Boat Accessories for all your outfitting needs.

When you're unsure, send us a photo of your transom measurement and a description of where you run the boat. Our technicians have two decades of experience matching motors to hulls, and we'd rather get you the right part the first time than process a return.

Non-OEM parts vary widely in quality. Some aftermarket manufacturers use the same production lines as OEM suppliers and deliver identical specs at lower prices. Others cut corners on materials and tolerances. We stock the former. You get factory-spec fit and finish without the dealer premium, and we stand behind every part we ship.

After every run, especially in saltwater, flush your outboard with fresh water for at least 10 minutes. Hook a hose to the flushing port or use muffs over the intakes, run the engine at idle, and let clean water push out the salt and sediment. This keeps your cooling passages clear and prevents corrosion in the lower unit. A long shaft in shallow water picks up more sand and silt, so flushing becomes even more critical. For detailed tips, see Saltwater Use and Overheating: Prevention Tips.

For everything from water pump impellers to carburetor repair kits, find OEM quality direct from factory boat parts on JLM Marine.

Hi—I’m Jim Walker

I grew up in a Florida boatyard, earning pocket money (and a few scars) by rebuilding outboard carbs before I could drive. That hands-on habit carried me through a Ph.D. in mechanical engineering, where I studied how salt water quietly murders metal.

I spent ten years designing cooling systems for high-horsepower outboards, then joined JLM Marine as CTO. We bench-test every new part in the lab, but I still bolt early prototypes onto my own 23-foot skiff for a weekend shake-down— nothing beats real wake and spray for finding weak spots.

Here on the blog I share the fixes and shortcuts I’ve learned so your engine—and your day on the water—run smooth.

Для владельцев лодок:

Мы надеемся, что следующие ресурсы окажутся полезными для вас в обслуживании и ремонте ваших судовых двигателей:

- Руководство по серийным номерам Mercury

- Руководства пользователя от Mercury

- Официальное руководство по номерам моделей в формате PDF от BRP

- Руководство по серийным номерам Johnson

-

Аксессуары для лодок от JLM Marine

О компании JLM Marine

Основанная в 2002 году, компания JLM Marine зарекомендовала себя как специализированный производитель высококачественных морских деталей, базирующийся в Китае. Наша приверженность совершенству в производстве заслужила нам доверие ведущих мировых морских брендов.

Как прямой поставщик, мы обходим посредников, что позволяет нам предлагать конкурентоспособные цены без ущерба качеству. Такой подход не только поддерживает экономическую эффективность, но и гарантирует, что наши клиенты получают наилучшую ценность напрямую от источника.

Мы рады расширить свое присутствие через розничные каналы, предлагая наш опыт и приверженность качеству непосредственно владельцам и любителям лодок по всему миру.

Leave a comment

Please note, comments need to be approved before they are published.