Installing a Jack Plate: Benefits for Shallow Water Boating

- Why Jack Plates Matter for Shallow Water Access

- How Motor Height Affects Speed and Fuel Economy

- Accessing Shallow Fishing Spots

- Comparison: Manual vs. Hydraulic Jack Plates

- How to Install a Hydraulic Jack Plate

- Operating a Jack Plate in Different Conditions

- Choosing the Right Jack Plate

- Maintenance and Troubleshooting

Why Jack Plates Matter for Shallow Water Access

If your boat won't make it into the back creeks or over sandbars without grinding the prop, you need to fix your motor height. A jack plate mounts between your transom and outboard, giving you vertical adjustment and setback. Raise the motor, reduce your draft, and run shallower water without tilting the engine up and losing steering control.

Hydraulic units let you adjust on the fly with a dash switch. Manual plates require you to stop, pull pins, and reset—fine for weekend use, but useless when you need to adapt mid-run. We see both types in the shop. The hydraulic ones cost more upfront—$800 to $1,500 compared to $125 to $350 for manual—but the ability to raise or lower while underway is worth every dollar if you fish tight water regularly, according to Boating Magazine's installation guide.

How Motor Height Affects Speed and Fuel Economy

Mounting the motor too low creates drag. The prop digs deep, the submerged lower unit churns turbulence, and you lose speed while burning more fuel. Raising the motor 4 to 8 inches cleans up the water flow to the prop and reduces resistance. Boating Magazine's testing showed 1 to 2 mph gains at the same RPM just from lifting the motor.

In one test we reviewed, a cabin boat with twin Dometic Mega Jackplates dropped 100 RPM at cruise speed when the engines were raised 3 inches—same boat speed, less engine load, per Boating Magazine's report. That's direct fuel savings. Over a season, the efficiency gain adds up, especially if you run long distances to fishing spots.

The setback also matters. Moving the motor 4 to 10 inches farther from the transom lets cleaner water hit the prop. Less turbulence means better bite, faster hole shots, and smoother planing. The prop works in undisturbed flow instead of the mess coming off the hull bottom.

Accessing Shallow Fishing Spots

Jack plates open up water you can't reach otherwise. Raise the motor all the way up, skim over flats in a foot of water, and get into backwater areas other boats avoid. Elite Series angler Russ Lane, speaking on his setup, said hydraulic jack plates are "extremely important" for rivers with shallow backwaters, letting him run full speed in skinny water where fixed mounts would bottom out.

Tournament time savings: A Bassmaster Elite pro leading on the St. John's River used his jack plate to plane in and out of shallow backwater instead of idling. He gained 30 minutes of fishing time per day—time he wouldn't have had without the plate. In competition, that's the difference between winning and going home empty.

Hole shot control: FLW pro Brian Latimer explained his technique—raise the plate for shallow exits, then drop it partway during the hole shot to avoid cavitation and get better prop grip. You're adjusting for conditions in real time, not stuck with one fixed height.

Charter captain Danny Allen, who's run Bob's Machine Shop jack plates for over 15 years on inshore boats, credits the plates for quicker hole shots and better engine water supply in skinny water. Lifting the motor vertically avoids the transom suction you get when you just tilt the engine up.

Comparison: Manual vs. Hydraulic Jack Plates

Manual plates offer fixed setback and adjustable height via pin settings. You get some benefit, but you're stopping the boat every time you need to change height.

Manual plate limitations:

- Requires stopping and manual adjustment

- Pin mechanisms can corrode and seize in saltwater

- No on-the-fly height changes for varying conditions

- Costs $125–$350

Hydraulic plate advantages:

- Dash-mounted switch for instant adjustment

- Height changes while underway

- Better for tournament fishing and frequent shallow-water transitions

- Costs $800–$1,500

We've pulled seized manual plates off boats where the owner gave up trying to adjust them. The pins rust, the threads bind, and eventually they just leave it in one position. Hydraulic units use sealed rams and fluid systems—less exposure to corrosion, easier maintenance.

If you only boat weekends on one lake and don't need to adjust often, save the money and go manual. If you fish tournaments, run tidal creeks, or navigate fluctuating river levels, the hydraulic is the only option that makes sense.

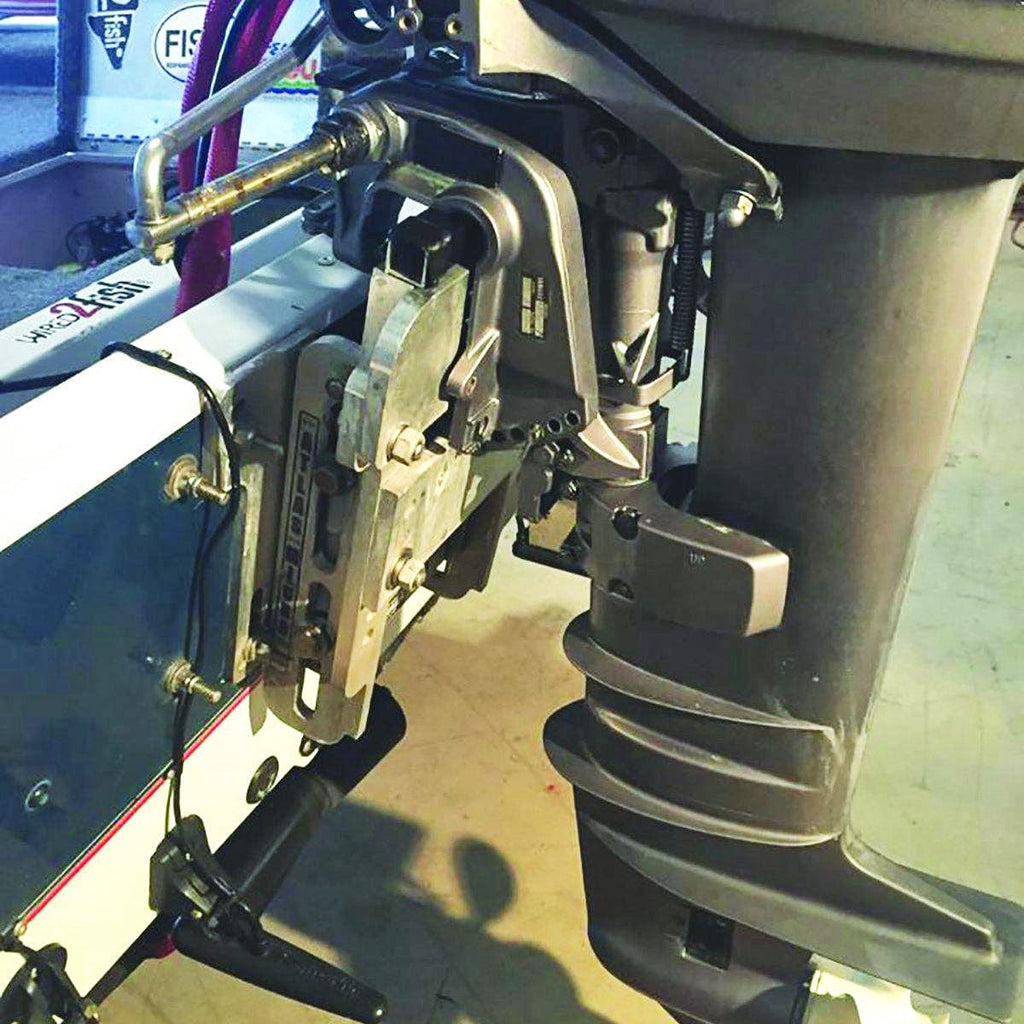

How to Install a Hydraulic Jack Plate

Tools needed:

- Socket set with wobble extensions

- Torque wrench

- Marine sealant (3M 5200 for permanent, 4200 for semi-permanent)

- Hoist or engine lift

- Circuit tester

- Wire crimpers and marine-grade connectors

Steps:

Remove the outboard using a hoist. Don't skip this—trying to work around the motor is a waste of time.

Fit the plate to the transom. Use the manufacturer's template to mark bolt holes. Drill if needed, apply marine sealant to each hole, and insert 1/2-inch bolts from inside the transom. Secure with washers and locknuts, torqued to the plate manufacturer's spec (usually 35–40 ft-lbs, but check the manual).

Mount the hydraulic pump and relays near the stern, away from spray. Route the wiring forward to the battery, using a circuit breaker rated for the pump's amperage draw (typically 30–40 amps). Install the dash switch, run the control wires back to the relays, and double-check all connections with a circuit tester before powering up.

Hoist the motor back onto the jack plate. Align the motor mounting holes, bolt it down, and reconnect steering cables, fuel lines, and electrical connections. If your steering cable is now too short because of the added setback, you'll need to replace it with a longer one—measure the added distance and add that to your existing cable length.

Pre-installation checklist:

- Confirm steering cable length accommodates setback

- Check hydraulic hose clearance around the motor tilt tube

- Verify transom thickness supports the plate's bolt length

- Ensure battery capacity handles the hydraulic pump draw

For quality parts like marine-grade sealant and connectors, you can find direct factory options to ensure durable, reliable installation.

Operating a Jack Plate in Different Conditions

Shallow water: Raise the plate all the way up. This lifts the prop as high as possible, letting you skim over flats, sandbars, and rocky creeks without grinding the lower unit. Ryan from Wired2Fish ran an 18-foot bass boat in 3 feet of water with a 6-inch jack plate lift, improving both hole shot and top speed on small rivers.

Hole shot: Start with the plate fully raised so the prop bites clean water without the lower unit creating drag. Once you're on plane, lower the plate gradually until you find the sweet spot—usually 2 to 2.5 inches below max height for cruising, according to Sportsman Boats tech rep Chase.

Cruising speed: The ideal height is just below the surface, where the prop grips efficiently without excessive drag. Too high and you'll get cavitation; too low and you're wasting fuel. Adjust incrementally—raise it 1 inch at a time until you feel the RPMs climb without losing boat speed. Back it off half an inch and lock it there.

Rough water: Drop the plate down. You need more prop bite to cut through chop and maintain control. Running too high in rough conditions causes the prop to ventilate on wave tops, and you lose thrust when you need it most.

Tight turns: Be cautious with max height in hard turns. The prop can break the surface and cavitate, causing a sudden loss of power mid-turn. Lower the plate slightly before entering sharp corners at speed.

Water pressure monitoring: Install a water pressure gauge if you don't have one. Raising the motor too high can reduce water flow to the cooling system, leading to overheating. The gauge will drop if you're not getting enough flow—lower the motor immediately if you see pressure fall below normal range. For detailed maintenance on your outboard water pump and cooling system, see our Johnson/Evinrude Outboard Water Pump Replacement Guide.

Choosing the Right Jack Plate

Setback options: Plates range from 4 to 14 inches of setback. More setback improves water flow but moves weight farther aft, which can affect handling on smaller boats. For most bass boats and bay boats, 6 to 8 inches is the standard. Bigger offshore boats can handle 10+ inches.

Weight capacity: Match the plate's weight rating to your motor. Plates range from 30 to 70+ pounds and are rated for specific outboard weights. Undersizing the plate will cause premature wear or failure.

Pump location: Integrated pumps mount directly on the plate. Remote pumps install elsewhere in the boat and connect via hydraulic lines. Integrated is simpler and lighter; remote is easier to service and keeps the pump away from saltwater spray.

Vertical travel: Most hydraulic plates offer 5 to 8 inches of vertical lift. More travel gives you more range, but 6 inches is usually enough for shallow-water fishing and performance tuning.

Explore high-quality boat accessories and hydraulic components suitable for custom jack plate setups from trusted factory sources.

Maintenance and Troubleshooting

Common issues:

Relay clicking but no movement: Check the hydraulic fluid reservoir. Low fluid means air in the lines. Top off and bleed the system by cycling the plate up and down several times.

Slow operation: Weak battery or corroded connections. Test voltage at the pump during operation—if it's below 11 volts, the pump won't run efficiently. Clean terminals, charge the battery, and retest.

Plate drifts down under load: Internal seal failure in the ram. This requires a rebuild kit or replacement ram. Don't ignore it—the plate can drop suddenly, grounding your prop at speed.

Pump runs but plate won't move: Hydraulic line blockage or failed solenoid valve. Disconnect lines and check for kinks or debris. Replace the valve if the lines are clear.

Routine maintenance: Grease the slide rails every 20 hours of operation. Wipe down the rams with a clean rag after every saltwater trip to prevent corrosion. Check mounting bolts quarterly—vibration can loosen them over time. Inspect hydraulic hoses for cracks or abrasion, especially where they pass near the motor tilt tube.

Keep a spray bottle of freshwater in the boat and rinse the jack plate after running in salt or silty water—this simple habit prevents most long-term corrosion issues. For greasing tips and marine lube options, see our Best Marine Greases and Lubes for Your Outboard guide.

For a wide range of genuine marine parts and accessories, including those for outboards, visit JLM Marine.

Hi—I’m Jim Walker

I grew up in a Florida boatyard, earning pocket money (and a few scars) by rebuilding outboard carbs before I could drive. That hands-on habit carried me through a Ph.D. in mechanical engineering, where I studied how salt water quietly murders metal.

I spent ten years designing cooling systems for high-horsepower outboards, then joined JLM Marine as CTO. We bench-test every new part in the lab, but I still bolt early prototypes onto my own 23-foot skiff for a weekend shake-down— nothing beats real wake and spray for finding weak spots.

Here on the blog I share the fixes and shortcuts I’ve learned so your engine—and your day on the water—run smooth.

For Boat Owners:

To assist you in maintaining and repairing your marine engines, we hope the following resources may be of use:

- Mercury Serial Number Guide

- Owner's Manuals from Mercury

- Official Model Number Reference Guide PDF from BRP

- Johnson Serial Number Guide

-

Boat Accessories from JLM Marine

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.