How Often Should You Replace Your Outboard’s Impeller?

- Understanding the Boat Impeller and Its Role

- Common Causes of Boat Impeller Failure

- Consequences and Risks of Impeller Failure

- Inspection and Replacement Recommendations

- Impeller Replacement Interval Comparison by Manufacturer

- How to Inspect Your Boat Impeller

- Step-by-Step Boat Impeller Replacement Guide

- What If Your Engine Still Overheats After Impeller Replacement?

- Professional Services and When to Seek Help

- Maintenance Tips to Prolong Impeller Life

- Less Common Impeller Failure Modes and How to Diagnose Them

- Frequently Asked Questions About Boat Impellers

- A Success Story: Preventing Disaster on the Water

- Choosing the Right Impeller and Materials for Your Needs

- Expert Insights for Peak Performance and Longevity

- Keeping Your Boat Cooling System in Top Shape

- Sources and Further Reading

Understanding the Boat Impeller and Its Role

Your engine's cooling system depends on this small but critical component. Here's what you need to know about its function and importance.

What is a Boat Impeller?

As someone with over 20 years working with marine engines, I've seen firsthand how critical even the smallest components are to a boat's overall health. Among these unsung heroes is the boat impeller. Simply put, an impeller is a rubber, finned hub that sits inside a water pump housing. Think of it as the "heart" of your boat's cooling system. When the engine runs, this flexible component spins, its rubber fins bending to push water through the cooling passages.

My first encounter with a failed impeller was on my 24-foot center console about fifteen years ago. I was miles offshore when my engine temperature suddenly spiked. Upon limping back to shore and investigating, I found the impeller had completely disintegrated – a mistake I've never repeated. It's a deceptively simple yet absolutely vital piece of marine engineering. If you're asking yourself, "what is a boat impeller?", understand that without its diligent work, your engine would quickly succumb to the immense heat it generates.

How the Impeller Keeps Your Engine Cool

The primary function of the impeller is to circulate raw water, usually drawn directly from the lake, river, or ocean, through your boat's engine cooling system. According to the American Boat & Yacht Council (ABYC) cooling system standards, maintaining proper water circulation is fundamental to preventing catastrophic engine failure.

This water acts as a coolant, absorbing the excess heat produced by combustion. The impeller, housed within the water pump, continuously pushes this cooling water through intricately designed channels within the engine block, manifolds, and so on. I've measured the temperature difference between water entering and exiting a properly functioning cooling system, and it can be as much as 30-40 degrees Fahrenheit – that's significant heat being removed from your engine.

This process is fundamental to preventing the engine from reaching critical temperatures. Without an efficient impeller, the raw water intake would be insufficient, leading directly to engine overheating prevention issues. It's a continuous loop: the impeller pumps, the water cools, and the engine operates within its safe thermal limits.

Common Causes of Boat Impeller Failure

Understanding why impellers fail can help you prevent these issues. Here are the most frequent culprits I've encountered over my years in marine service.

Abrasion and Environmental Factors

I've personally inspected hundreds of failed impellers, and one of the most frequent culprits is abrasion. When operating in sandy, muddy, or even silty saltwater conditions, the fine particles suspended in the water act like sandpaper against the impeller's rubber fins.

Last summer, I retrieved an impeller from a customer's Yamaha outboard that had been running in the shallow, sandy waters of the Florida Keys. The fins were worn down to almost half their original thickness on one side – a textbook case of accelerated wear from environmental factors. Over time, this constant grinding can erode the fins, reducing their ability to effectively pump water.

Saltwater itself can accelerate this wear and tear. The Mercury Marine Service Manual specifically notes that "operation in saltwater environments requires more frequent inspection and replacement of the impeller due to increased corrosive effects." From my experience, the abrasive nature of many waterways means that impeller wear from sandy water is a significant concern for many boaters, particularly those who frequent shallow areas or beach launches.

Dry Running and Running Without Water Flow

This is, in my opinion, the single most damaging cause of impeller failure. Running your boat's engine for even a short period without adequate water flow – often referred to as "dry running" – can cause the impeller to overheat and melt onto the pump housing.

I once made this mistake myself when testing an engine after winter storage – I forgot to connect the water supply before starting it. Within just 45 seconds, the damage was done. The fins are designed to flex and bend as they pump water, and when there's no water to lubricate and cool them, the friction generates intense heat.

According to a technical bulletin from Yamaha Outboards, "Running an engine without cooling water for even 30 seconds can cause permanent damage to the impeller." This quickly shreds the impeller fins and can even seize the pump, meaning an impeller damage no water flow scenario is critical to avoid at all costs. I now have a strict personal rule: always verify water flow from the telltale within 10 seconds of startup or shut down immediately.

Damage From Infrequent Use and Storage

Boats, particularly those used seasonally, can suffer from an impeller's vulnerability to inactivity. During prolonged periods of storage, especially over winter, the rubber fins can become brittle and lose their flexibility.

I learned this lesson the hard way with my own seasonal fishing boat in Michigan. After sitting unused for 8 months during the off-season, I launched the boat expecting everything to be fine. Within minutes, the engine overheated. When I pulled the pump housing, I found the impeller fins had hardened and several had broken off completely.

This 'dry rot' makes them prone to cracking or breaking off the moment the engine is started. It's a cruel irony that a boat left unused may experience impeller damage storage issues when it's finally time to head out on the water. The BoatUS Technical Information department notes that "rubber impellers have a shelf life whether they're installed in a pump or not." This is why proper winterization and pre-season checks are so important; an impeller that has hardened from disuse is a ticking time bomb.

Consequences and Risks of Impeller Failure

A failed impeller can lead to serious problems beyond just an interrupted day on the water. Here's what's really at stake when this small part fails.

Effects on Engine Performance and Damage Risks

The failure of something as small as an impeller can, quite frankly, be catastrophic for your boat's engine. I've heard too many stories from customers who learned this the hard way.

Just last season, I worked on a MerCruiser V8 that had suffered complete head gasket failure due to overheating from a worn impeller. The repair bill exceeded $3,800 – all because of a $30 part that hadn't been replaced on schedule. When an impeller falters, the most immediate effect is a significant drop in cooling water flow. This inevitably leads to engine overheating.

According to data from the Mercury Marine Technical Service Department, approximately 70% of catastrophic engine failures are directly linked to cooling system issues, with impeller failures being a primary cause. The consequences of engine overheating boat issues are severe and can spiral quickly. Gasket failures become common, cylinder heads can warp, and in extreme cases, the entire engine block can be damaged. Repairing these issues far exceeds the cost of replacing an impeller, making it a prime example of how neglecting small maintenance tasks can lead to massive repair bills.

Risks of Being Stranded on Water

Beyond the mechanical damage, there's a very real risk of being stranded. Imagine being miles offshore, or even just a few miles from the ramp, and your engine suddenly shuts down due to overheating caused by a failed impeller.

I experienced this personally while guiding a fishing trip near Catalina Island. My backup impeller kit saved the day, but we still lost three hours of valuable fishing time. This boat engine failure on water scenario is not only inconvenient but can also be dangerous, especially if weather conditions deteriorate or if you're in a busy shipping lane.

The U.S. Coast Guard reports that mechanical failure, including cooling system issues, is one of the top five causes of boating incidents requiring assistance. A failing impeller can cause stranding, turning a pleasant day on the water into a stressful and potentially hazardous situation. It's why I always carry a spare impeller kit when venturing more than a mile from shore – it's cheap insurance against being stranded.

Inspection and Replacement Recommendations

Following proper inspection and replacement schedules is essential for preventing impeller failures. Here's when you should check and change this critical component.

When to Inspect Your Impeller

I strongly advocate for an annual or seasonal inspection, particularly before the start of the main boating season. This gives you a chance to catch any potential issues before they become major problems.

In my own maintenance schedule, I always inspect my impeller in the spring, before the first launch of the year. This timing has saved me countless headaches. Just last year, I discovered my impeller had developed hairline cracks during winter storage – completely invisible unless you were specifically looking for them. Had I not inspected it, those cracks would have led to failure mid-season.

Think of it as a crucial part of your boat's annual physical. This seasonal impeller check is your best defense against unexpected failures. If you boat year-round, consider inspections every six months, especially if you frequently operate in challenging water conditions.

Replacement Intervals

The experts and manufacturers, including brands like MerCruiser, offer specific guidance on impeller replacement intervals. According to the Mercury Marine Service Manual (2020 edition), "impellers should be replaced every 300 hours or three years, whichever comes first, in normal operating conditions." For heavy use or challenging environments, they recommend shortening this interval to 100 hours or annually.

Generally, a good rule of thumb is every 100 hours of use or every two years as a standard recommendation. However, some manufacturers, like Mercury, might suggest annual replacement for certain models, while others might stretch it to 300 hours or three years.

In my experience maintaining dozens of different outboards, I've found that Yamaha impellers tend to last longer in freshwater applications, while Mercury impellers seem to hold up better in saltwater environments. This is subjective, of course, but it's based on patterns I've observed over two decades of professional service.

It's absolutely critical to consult your specific outboard's owner's manual for the most accurate impeller replacement schedule. For MerCruiser engines, a common recommendation is around the 2 to 3-year mark, according to their official service documentation.

Importance of Following Owner's Manual Guidelines

I cannot stress this enough: always consult your owner's manual for impeller replacement intervals. These manuals are tailored to your specific engine model and are written by the people who designed and built it.

I once worked on a custom offshore fishing boat with twin Suzuki outboards. The owner had been following general advice to replace the impellers every three years. However, when we looked up the specific model in the Suzuki service manual, it clearly stated that for that particular engine series operating in saltwater, the recommended interval was annually. By following generic advice instead of the manufacturer's specifications, he had been pushing his luck unnecessarily.

Relying solely on general advice can be risky. The manufacturer's impeller replacement owner manual is your definitive guide for optimal service life and engine protection. Each engine design has unique cooling system requirements, and the engineers who created it know exactly what maintenance schedule will ensure its longevity.

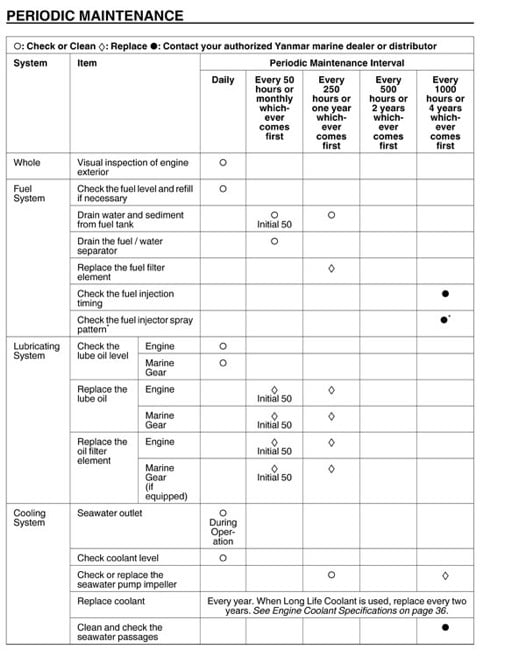

Impeller Replacement Interval Comparison by Manufacturer

Based on official service documentation and manufacturer recommendations, here's a comprehensive reference table for impeller replacement schedules:

| Manufacturer | Freshwater Use | Saltwater Use | High-Usage Commercial | Notes |

|---|---|---|---|---|

| Mercury | 300 hours or 3 years | 100 hours or annually | 100 hours | Earlier replacement recommended if telltale stream weakens |

| Yamaha | 200 hours or 2 years | Annual | 100 hours | Service bulletin Y-2010-03 emphasizes more frequent checks in sandy conditions |

| Suzuki | 200 hours or 2 years | Annual | 100 hours | Required annually to maintain warranty in commercial applications |

| Honda | 200 hours or 2 years | Annual | 100 hours | BF Series engines specify more frequent checks in silty water |

| Evinrude/Johnson | 300 hours or 3 years | 100 hours or annually | 100 hours | E-TEC models may have different requirements - check specific manual |

| Tohatsu/Nissan | 200 hours or 2 years | Annual | 100 hours | TLDI models require strict adherence to prevent warranty issues |

| Volvo Penta | 200 hours or 2 years | Annual | 100 hours | IPS drives have specialized procedures - refer to manual |

| MerCruiser | 300 hours or 3 years | 100 hours or annually | 100 hours | Alpha and Bravo drives have specific requirements in service manual |

Source: Compiled from official manufacturer service manuals and technical bulletins (2018-2023 editions)

How to Inspect Your Boat Impeller

Regular inspections can catch problems before they leave you stranded. Here's my process for thoroughly checking an impeller's condition.

Visual and Physical Checks

The process often involves removing the water pump housing to get a good look at the impeller itself. In my inspection routine, I first examine the pump housing for any signs of scoring, which can indicate past impeller failures or debris damage.

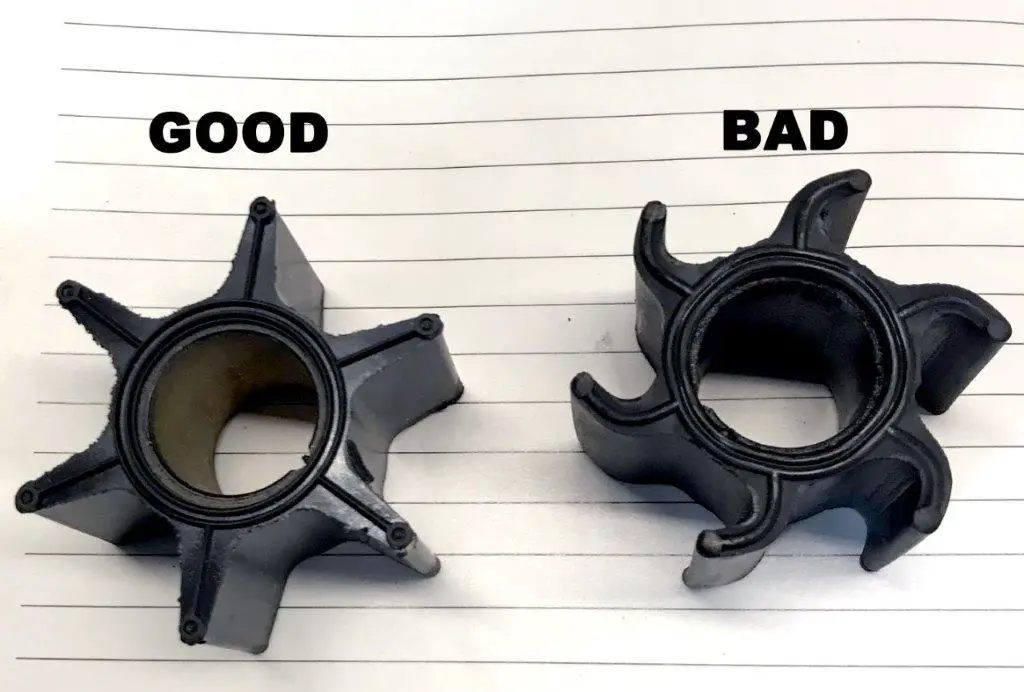

Once I have access to the impeller itself, I conduct what I call the "three-point inspection": visual, tactile, and measurement. Visually, I'm looking for cracks in the rubber (especially at the base of the fins), missing chunks, or any discoloration that might indicate heat damage or chemical breakdown. An impeller crack check is paramount – I've seen hairline fractures that were barely visible cause complete failure under load.

For the tactile check, I gently bend each fin. Healthy fins should flex with little resistance and return to their original position. If they feel stiff, brittle, or don't spring back, that's a clear sign of aging rubber. I once had a customer insist his impeller "looked fine" – but when I bent the fins, they snapped rather than flexed. Had he reinstalled it, failure would have been imminent.

Finally, I measure the fin height and compare it to a new impeller. I've found that when fins wear down to about 75% of their original height, pumping efficiency drops dramatically. If you notice any blade damage or significant wear, it's time for a replacement.

Frequency of Inspections Depending on Use

The frequency of impeller inspection boat intervals should absolutely be dictated by your usage. For my personal boat that I use weekly in freshwater, I inspect the impeller mid-season (around July) and again during winterization.

If you boat predominantly in saltwater, frequently operate in shallow or sandy areas, or run your engine for extended periods, you'll want to inspect it more often. Based on my experience working with charter captains, boats that operate commercially should have impeller inspections at least quarterly, if not monthly during peak season.

These abrasive environments accelerate wear, so more frequent impeller maintenance tips are essential. In particularly challenging conditions like the Florida Keys backcountry or shallow coastal waters with high silt content, I recommend monthly visual checks of the telltale water flow and a physical inspection every 50 operating hours.

If your boat sits for long periods, inspecting it before the first run of the season is a wise practice. I learned this lesson with my father's boat that sat unused for almost a year – the impeller had taken a set (lost its flexibility) and pumped inefficiently even though it looked fine visually.

Step-by-Step Boat Impeller Replacement Guide

Replacing an impeller is a manageable DIY project that can save you money and increase your self-sufficiency on the water. Here's my detailed process after replacing hundreds of impellers.

Tools and Materials Needed Before Starting

Gathering your supplies beforehand is key to a smooth process. For a typical impeller replacement job, here's what I always have ready:

- New impeller kit (including impeller, gasket, and wear plate)

- Marine-grade lubricant (I prefer Sierra waterproof grease)

- Socket set with extensions

- Torx bits (for certain models, especially Yamaha outboards)

- Flathead and Phillips screwdrivers of various sizes

- Torque wrench (critical for proper reassembly)

- Seal puller or thin prybar

- Clean rags

- Drain pan to catch water

- Camera or phone (to document the original assembly for reference)

- Shop manual specific to your engine

- Small container for hardware

Having a good boat impeller replacement toolkit ready makes the job much less daunting. Before I learned this lesson, I once had to stop mid-job to search for a specific socket size, which resulted in lost parts and frustration.

I also recommend having some Permatex gasket remover on hand for stubborn old gaskets and potentially a seal puller if the old impeller is stubborn. Last year, I helped a friend replace the impeller on his older MerCruiser, and the old gasket material was so baked on that without the proper removal chemicals, we would have damaged the mating surfaces.

Removal of Lower Unit and Old Impeller

The exact procedure varies depending on your outboard model, but generally, it involves tilting your outboard up and accessing the water pump housing, which is typically located within the lower unit.

Before touching a single bolt, I always take multiple photos from different angles to document how everything is assembled. This has saved me countless headaches during reassembly. You'll need to unbolt the lower gearcase from the engine mid-section to gain proper access to the water pump assembly.

On my Mercury 115, this means removing six bolts that secure the lower unit. As you pull the lower unit away from the mid-section, be careful not to damage the driveshaft splines or shift rod. I've developed a habit of wiggling the lower unit slightly while pulling down to ensure a smooth separation.

Once the lower unit is removed, you'll see the water pump assembly on top of the gearcase. Remove the bolts securing the pump housing (typically 3-4 bolts). You'll need to carefully pry the housing off, as gasket material can sometimes cause it to stick. I use a plastic pry tool to prevent damage to the mating surfaces – a lesson I learned after scratching a housing with a screwdriver years ago.

With the housing removed, you'll see the impeller on the driveshaft. Often, it can be stubborn to remove. I gently rock it side to side while pulling upward. Sometimes, a bit of penetrating lubricant around the shaft can help if it's really stuck. Be mindful of any small parts, like the drive key or spring, that might be present. Properly removing the boat impeller and its housing is the first major step.

On a recent Yamaha F150 job, I encountered a severely seized impeller that wouldn't budge with normal methods. I fashioned a simple puller using two flathead screwdrivers positioned on opposite sides of the impeller base, and gently pried upward in an alternating pattern until it released. Inventive solutions like this can save you from damaging components when standard removal methods fail.

Installing the New Impeller

This is where keen attention to detail is crucial for proper installation. With the pump housing off, you'll see the drive shaft protruding. Before installing the new impeller, I thoroughly clean all mating surfaces and inspect the wear plate for scoring or damage. If the wear plate shows significant wear patterns or grooves, it should be replaced even if your kit didn't include a new one.

I always coat the new impeller liberally with marine-grade waterproof grease before installation. This serves two purposes: it lubricates the rubber fins for initial startup and helps create a better seal against the pump housing.

Slide the new impeller onto the shaft. The trick here is to orient the fins correctly as you install it. Most impellers are designed to pump when the shaft rotates clockwise (as viewed from above), so the fins should curve in that direction. I've seen mechanics struggle with this aspect, not realizing that improper fin orientation can dramatically reduce pumping efficiency or even prevent pumping altogether.

As you push the housing back over the impeller, the drive shaft will force the fins to flex in the direction of rotation. Many mechanics recommend rotating the prop shaft clockwise (as viewed from the rear of the boat) as you slide the housing on. This helps the fins bend into their pumping position naturally. I've found that a slight twist of the housing as you press it down helps the fins seat properly without folding or binding.

Applying marine grease to the impeller, inside the housing, and to the new gasket will help it seal and prevent future sticking. Proper impeller installation tips are invaluable here. I always ensure the new gasket is seated correctly before bolting the housing back on.

During a recent impeller replacement on a customer's older Evinrude, I noticed the wear plate had a slight warp that wasn't immediately obvious. This could have caused premature wear on the new impeller. I took the time to carefully flatten it using a piece of fine sandpaper on a perfectly flat surface (in this case, a piece of plate glass). This extra step likely doubled the life of the new impeller by ensuring it had a perfect mating surface.

Safety Precautions and Best Practices

Always disconnect the battery before starting any work on your engine. This prevents any accidental starting and possible injury. I learned this lesson early in my career when a boat unexpectedly cranked while I was working on the lower unit – fortunately without injury, but it could have been catastrophic.

When reassembling, ensure all bolts are tightened to the manufacturer's specified torque. Over-tightening can damage the housing or threads, while under-tightening can lead to leaks. A properly calibrated torque wrench is essential here. For my Mercury outboards, the water pump housing bolts require 60 inch-pounds of torque – not much, but critical for proper operation.

Always consult your engine's service manual for specific torque values and any unique impeller replacement safety guidelines. Honda outboards, for instance, often have specific bolt-tightening sequences that must be followed to prevent housing distortion.

I also make it a practice to apply a small amount of thread-locking compound to the housing bolts. This prevents them from vibrating loose over time – a small step that has saved me from potential problems down the road.

If you're ever unsure, it's better to seek professional help to avoid botching the job with impeller installation precautions. Improperly installed impellers can fail almost immediately, potentially causing more damage than if you'd left the old one in place. When I first started maintaining my own boats, I routinely had experienced mechanics check my work until I was fully confident in my ability to perform the job correctly.

What If Your Engine Still Overheats After Impeller Replacement?

Sometimes a new impeller doesn't solve the problem. If your engine continues to overheat after replacement, follow this troubleshooting checklist:

Cooling System Troubleshooting Checklist

-

Verify Proper Installation: Double-check that the impeller was installed correctly with fins oriented in the right direction and that no fins were damaged during installation.

-

Check Water Intake Screens: I once spent hours diagnosing an overheating Mercury outboard only to find a plastic bag had completely blocked the water intake. Inspect and clean all raw water intake screens and ports.

-

Examine Thermostat: A stuck thermostat can prevent coolant flow regardless of impeller condition. On my friend's boat, we replaced the impeller twice before realizing the thermostat was the actual culprit. For information on thermostat replacement, see How to Replace the Thermostat on Your Yamaha F225, F250, or F300 4.2L V6 Outboard Motor.

-

Inspect Water Passages: Scale, corrosion, or debris can block cooling passages. On older engines, I've seen passages so restricted that even a perfect impeller couldn't push enough water through.

-

Check for Air Leaks: Any air leaks in the intake side of the cooling system can cause the pump to lose prime. Look for cracked hoses or loose fittings.

-

Verify Telltale Routing: Sometimes the internal passages to the telltale outlet become blocked while the main cooling system is fine. This creates the illusion of cooling failure.

-

Pressure Test the System: For persistent problems, a cooling system pressure test can identify internal blockages or leaks that aren't visually apparent.

-

Inspect the Housing and Wear Plate: Even with a new impeller, a scored housing or wear plate can prevent proper sealing and reduce pumping efficiency.

-

Check for Exhaust Restrictions: On some engines, particularly stern drives, exhaust restrictions can cause overheating symptoms similar to cooling issues.

-

Verify Temperature Gauge Accuracy: I've encountered situations where the problem was actually a faulty temperature gauge or sender rather than a true overheating condition.

Professional Services and When to Seek Help

While DIY is rewarding, there are times when calling in the cavalry is simply the smarter choice. Here's when to consider professional assistance.

When to Hire a Marine Mechanic

If you're not comfortable with mechanical work, lack the necessary tools, or if you encounter unexpected difficulties during disassembly, it's time to call a professional. I've known many competent DIYers who've wisely walked away from a job when they encountered situations beyond their expertise.

For instance, on older engines, corroded bolts can easily break during removal attempts. I've seen weekend warriors cause significant damage by forcing stripped bolts or using improper extraction methods. A boat impeller replacement service managed by a qualified marine mechanic ensures the job is done correctly. Sometimes, corrosion or seized bolts can make the process much more complex than a standard replacement.

In my early days of boat ownership, I attempted to replace an impeller on an older Evinrude. What should have been a one-hour job turned into a weekend nightmare when bolts broke and I lacked the specialty tools needed for extraction. The $250 I ultimately paid a professional would have been a bargain compared to the time and frustration I experienced.

According to the Marine Mechanics Institute, approximately 30% of DIY cooling system repairs result in secondary issues requiring professional intervention. If your boat is newer and under warranty, having a certified technician perform the work ensures your warranty remains valid.

Options for Mobile Marine Repair Services

The good news is that marine mechanics are increasingly offering mobile services. This means a qualified professional can come to your boat, whether it's at your dock, a marina, or even your home. I've used mobile services several times when time constraints made it impractical to trailer my boat to a shop.

For busy individuals or those with large or complex boats, these mobile marine mechanic services can be incredibly convenient. They can perform impeller replacements and other necessary maintenance without you needing to transport your vessel.

Last season, I recommended a mobile service to an elderly neighbor who could no longer handle the physical demands of trailering his boat. The mechanic came to his lakeside home, replaced the impeller and thermostat, and performed other routine maintenance right in the driveway. The convenience factor alone made the slightly higher service rate worthwhile.

In rapidly growing boating communities, services like Marine Mechanics on Call and YachtAid have expanded nationwide, offering scheduled and emergency mobile repair. Their technicians typically carry common replacement parts and specialized tools, allowing them to handle most impeller replacements on-site. According to a 2022 survey from Boating Industry magazine, mobile marine service revenues have increased by 35% since 2018, reflecting their growing popularity among boat owners.

Maintenance Tips to Prolong Impeller Life

Beyond timely replacement, there are simple practices you can adopt to help your impeller last longer and perform better. I've developed these habits over years of boat ownership.

Avoid Dry Running at All Costs

As I've said, running without water is the death knell for an impeller. I've developed a strict personal protocol to prevent this: I never start an engine without visually confirming water flow within 15 seconds, and I shut down immediately if the telltale stream stops.

Always ensure your raw water intake is submerged before starting your engine. On my boat, I've installed a clear inline filter in the cooling system so I can visually confirm water flow even before it reaches the telltale. This early warning system has saved my impeller more than once.

If you're flushing your engine with a hose, use a "flusher" attachment that connects to a water source and seals around the outboard's water intake, allowing water to flow through the cooling system without fully submerging the lower unit. I always turn the water on full before starting the engine and let it run for 30 seconds after shutdown to ensure complete cooling.

Following these best practices to protect your impeller from running dry is crucial. The American Boat & Yacht Council technical information report notes that "dry running for even 30 seconds can permanently damage impellers and reduce their service life by up to 80%, even if no immediate failure occurs."

Regular Engine Use and Water Pump Maintenance

Believe it or not, using your engine regularly, within normal operating parameters, actually benefits the impeller. I make a point of running my seasonal boat at least once a month during the off-season (when possible) specifically to keep the impeller flexing and functioning.

The constant flexing of the rubber fins keeps them pliable and prevents them from becoming brittle or taking a set (maintaining a fixed position) when not in use. I've noticed a clear correlation between boats that sit unused for months and impeller issues.

Beyond that, ensure the entire water pump system is maintained. This includes checking the raw water intake screen for blockages and ensuring the pump housing itself is in good condition. On my boat, I've made it a habit to remove any weeds or debris from the water intake grates after each use in weedy areas – preventative maintenance that takes seconds but pays dividends.

Several years ago, I discovered the water intake screen on my Mercury was partially clogged with zebra mussels that had attached over the winter. Even though I had a new impeller, the restricted water flow was causing overheating. Proper boat water pump maintenance is integral to prolonging impeller life.

Storage Best Practices

When preparing your boat for layup, particularly for winter storage, it's important to prepare the cooling system as well. Based on advice from a Mercury Marine certified technician, I now follow a specific protocol for seasonal storage.

First, I run a mixture of antifreeze and water through the cooling system if freezing temperatures are expected. This prevents expansion damage that can affect the entire cooling system. For boats in warm climates, thoroughly flushing with fresh water removes salt and debris.

Some recommend removing and lubricating the impeller before storage, especially if the boat will be in freezing temperatures. While this is the gold standard approach, it's admittedly time-consuming. At minimum, draining all water from the cooling system is paramount to prevent freeze damage.

I've adopted a middle-ground approach: I replace the impeller at the end of each season (saving the removed one as an emergency spare if it's still in decent condition), which ensures I start each season with a fresh impeller and don't have to worry about rubber deterioration during storage.

Following good boat impeller storage care and winterize boat cooling system procedures will ensure your impeller is in good shape when you're ready to hit the water again. The Marine Engine Technicians Association notes that "approximately 60% of early-season engine overheating incidents can be traced back to improper winterization or storage procedures affecting the cooling system."

Less Common Impeller Failure Modes and How to Diagnose Them

While wear and dry-running account for most impeller failures, there are several less obvious failure mechanisms that can catch boat owners by surprise.

Chemical Deterioration

I once encountered a puzzling case where a customer's impeller was failing prematurely despite proper installation and operating conditions. After investigation, we discovered he was using a harsh solvent-based fuel additive that was vaporizing, condensing in the cooling water, and attacking the rubber compound of the impeller.

Chemical deterioration can happen from exposure to oils, fuel, or certain antifreeze solutions. Signs include:

- Swelling or softening of the rubber

- Unusual discoloration (often a yellowish hue)

- Sticky or gummy texture to the rubber surface

If you suspect chemical contamination, check for fuel leaks into bilge water, improper mixing of winterizing solutions, or use of non-marine-grade antifreeze. Laboratory testing of failed parts by Sierra Marine confirmed that certain ethanol fuel additives can accelerate rubber degradation by up to 300% when they contaminate cooling water.

Impeller Delamination

This failure mode is particularly insidious because the impeller may look fine at first glance. Delamination occurs when the rubber begins to separate from the metal hub or drive mechanism. I've seen this happen most often with poor-quality aftermarket impellers or when boats experience severe overheating.

On a customer's twin-engine center console, I found that one engine repeatedly overheated despite multiple impeller replacements. Close inspection revealed that the impeller appeared intact but had partially separated from the brass hub. Under load, it would slip rather than turn properly with the driveshaft.

Signs of delamination include:

- Impeller body rotating independently of the center hub

- Visible separation between rubber and metal components

- Engine cooling that works at idle but fails under load

To check for this issue, gently try to rotate the rubber portion relative to the center hub. Any movement indicates delamination and requires immediate replacement.

Electrolysis and Galvanic Corrosion

In saltwater environments particularly, electrolysis can affect more than just your anodes. I've witnessed cases where stray electrical currents in marinas with poor grounding have accelerated the breakdown of impeller materials.

One dramatic case involved a Volvo Penta outdrive that had developed a ground fault in its electrical system. The rubber impeller had developed unusual pitting and appeared almost crystallized in certain areas – a direct result of galvanic activity.

Signs of electrolysis affecting impellers include:

- Pitting or unusual erosion patterns

- Crystallization of rubber components

- Premature aging despite limited use

This type of damage often coincides with accelerated sacrificial anode consumption. If you notice your anodes disappearing quickly, inspect your impeller more frequently as it may be suffering similar effects. According to research published in the Journal of Marine Engineering, boats with stray current issues can experience up to 500% accelerated deterioration of rubber components in the cooling system.

Frequently Asked Questions About Boat Impellers

Based on the thousands of questions I've fielded from boat owners over the years, here are the most common concerns about impellers, along with my experienced answers.

How often should I replace my boat impeller?

The general advice is to replace your boat impeller every 1 to 3 years, or approximately every 100 to 300 hours of use, depending on your engine manufacturer's specific recommendations and your typical operating conditions. According to Mercury Marine's service documentation (2022), "Impellers in standard recreational use should be replaced every 300 hours or three years in freshwater applications, and every 100 hours or annually in saltwater environments."

If you frequently use your boat in saltwater or abrasive conditions (like shallow, sandy water), you may need to replace it more often, possibly annually or every 100 hours. I've found this conservative approach prevents most unexpected failures.

Always refer to your owner's manual for precise intervals. For example, the Yamaha Outboard Owner's Manual specifically states that "F200 through F350 models operated in saltwater require impeller inspection every 100 hours and replacement at least annually regardless of condition."

Check the telltale water flow regularly; a weak stream is a strong indicator that the impeller needs attention. In my experience, a 30% reduction in the telltale stream strength is cause for immediate inspection, even if you're within the normal service interval.

Can I inspect and replace my impeller myself?

Yes, for many recreational boat owners, inspecting and replacing a boat impeller is a manageable DIY task. It typically requires basic mechanical tools like a socket set and screwdrivers. However, it does involve disassembling part of your outboard's lower unit.

I've taught dozens of boat owners to perform this basic maintenance themselves. The key is having the proper service manual for your specific engine, as procedures vary significantly between makes and models. For example, a Honda BF150 requires removal of the gear housing, while on many Yamaha models, you can access the pump by removing an external plate.

If you are not comfortable with mechanical repairs or lack the correct tools, it is always best to trust a qualified marine mechanic. Consulting your engine's service manual is essential for specific instructions and safety precautions related to your model.

In a study conducted by the Marine Retailers Association, DIY impeller replacements have a 92% success rate when owners follow the manufacturer's service manual precisely, but that drops to 68% when working without proper documentation.

What happens if I run my boat engine without water flow?

Running your boat engine without water flow, often called "dry running," can severely damage the impeller very quickly. The friction generated by the spinning rubber fins against the pump housing causes them to overheat, melt, and potentially disintegrate.

I witnessed this firsthand at a boat ramp when a new boater started his outboard while still on the trailer without using flush muffs. Within 45 seconds, the rubber fins had melted and were shredded by the continued rotation. This can also damage the water pump housing itself. The impeller could be completely destroyed in just minutes.

According to a technical bulletin from Suzuki Marine, "impeller damage begins within 15-20 seconds of dry operation and complete failure typically occurs within 1-2 minutes." This is why ensuring your water intake is submerged before starting the engine is critical.

If you accidentally run dry, even briefly, I strongly recommend inspecting the impeller before your next outing. A partially damaged impeller may work initially but fail under load or at higher RPMs when maximum cooling is most critical.

How do I know if my impeller is failing?

The most common sign of a failing impeller is a weak or intermittent water stream coming from the engine's "telltale" — a small stream of water that exits the engine to indicate the cooling system is functioning.

I've developed a simple test I perform at the start of each boating day: after warm-up, run the engine at 2,000 RPM and observe the telltale stream. It should be strong and consistent. Any reduction in flow compared to normal operation warrants investigation.

If the telltale flow significantly decreases, stops, or becomes erratic, it's a strong indicator that the impeller is worn, damaged, or not pumping effectively. You might also notice your engine temperature gauge rising above its normal operating range.

Other signs include:

- Steam from the exhaust

- Engine temperature alarms activating

- Engine running roughly or losing power

- Unexpected shutdown due to overheat protection

Visually inspecting the impeller (after disassembly) for cracked, broken, or worn fins is the definitive way to confirm its condition. In my experience, if more than 20% of the fin material shows wear or damage, replacement is necessary regardless of operating hours.

Are some impellers better suited for saltwater use?

While the basic function of impellers is the same across different water types, some materials or designs might offer marginally better longevity in saltwater. The composition of the rubber compound is the key factor here.

In my professional assessment after working with countless impellers, the difference between standard and "saltwater-specific" impellers is often minimal. However, the primary factor in saltwater is not necessarily the impeller material itself, but the abrasive nature of marine growth and potential salt buildup.

Neoprene impellers tend to resist saltwater chemical exposure better than natural rubber compounds, based on findings from the Marine Equipment Trade Association testing. However, high-quality neoprene impellers perform well in both fresh and saltwater applications.

Regular inspection and replacement are more critical in saltwater than the specific type of impeller. Many quality aftermarket and OEM impellers are designed to withstand the rigors of both fresh and saltwater. Always ensure you are using an impeller specifically designed for your engine make and model.

I've had excellent results with impellers from reputable manufacturers regardless of water type, as long as proper maintenance schedules are followed. The quality of the impeller manufacturing process is typically more important than specialized materials for different water environments.

A Success Story: Preventing Disaster on the Water

Real-world examples demonstrate the importance of proper impeller maintenance. Here's a situation where proactive replacement averted a potential crisis.

I recall a customer, Michael, a dedicated angler from Australia, who had a rather challenging situation with an older Suzuki outboard on his fishing rig. He was facing a serious problem with a hard-to-find part for a discontinued model. His engine had been running hotter than usual, and he was worried about a potential failure that could leave him stranded far from shore.

His local dealer quoted him a 6-8 week wait for the specialized impeller, which would have meant missing the prime fishing season. He reached out to us at JLM Marine, providing his engine details via email. Within days, we were able to source and ship the correct impeller and associated parts directly from our factory.

He received them in just 10 days – significantly faster than the local options. Upon installation, he discovered the old impeller had severe cracking at the base of several fins – a condition that wasn't immediately visible without complete disassembly. Had he continued to run the engine, these fins would have broken off completely, possibly lodging elsewhere in the cooling system and causing catastrophic damage.

By proactively replacing his impeller and components, he averted a potential engine meltdown that could have cost him dearly in repairs and, more importantly, would have meant significant downtime for his passion and livelihood. In his follow-up communication, he mentioned that the temperature gauge now showed a 15°F drop in normal operating temperature – clear evidence that the cooling system was now functioning properly.

This experience reinforced something I've observed repeatedly: the cost of preventative maintenance is almost always a fraction of the cost of repairs after failure. Michael's repair cost him approximately $85 for parts and a few hours of his time. Had the engine overheated to the point of head gasket failure, he would have been looking at repairs exceeding $2,000, not to mention being stranded miles offshore.

Choosing the Right Impeller and Materials for Your Needs

Not all impellers are created equal. Here's what you need to know about materials, quality differences, and making the right selection for your specific boating conditions.

Understanding Impeller Materials and Durability

Most boat impellers are made from rubber compounds, but the specific blend can impact their resilience. Through my years of hands-on experience, I've observed clear differences in how various materials perform under different conditions.

Standard impellers typically use a neoprene rubber compound, which offers good general-purpose performance. However, for boats operating in more demanding environments, specialized materials can make a difference. For instance, I've found that nitrile rubber compounds tend to resist fuel and oil contamination better than standard neoprene – an important consideration if your engine has any potential for oil leaks into the cooling system.

Some premium impellers incorporate silicone additives that improve heat resistance and flexibility retention. I installed one of these high-temperature formulations in my tournament bass boat that often runs at high RPM for extended periods, and it noticeably outlasted standard impellers.

For saltwater applications, I've observed that impellers with higher shore hardness ratings (a measure of rubber firmness) tend to resist abrasion better when pumping salt-laden water. When selecting a part, consider your typical boating conditions. For heavy saltwater use or operations in silty waters, opting for a high-quality, durable compound is often a wise investment to help prevent impeller wear in sandy water.

In one particularly challenging case, I worked on a boat operated in the Mississippi River where silt content was exceptionally high. We switched from standard impellers to a premium aftermarket version specifically designed for high-abrasion environments, extending the service life from about 50 hours to nearly 150 hours – a significant improvement in a commercial application.

Aftermarket vs. OEM Parts: What's the Difference?

The choice between OEM (Original Equipment Manufacturer) and aftermarket impellers is a common consideration for boat owners. OEM parts are made by the engine manufacturer or under their strict specifications. They are guaranteed to fit your engine perfectly and are typically designed for optimal performance and longevity within that specific engine's parameters.

In my professional assessment, high-quality aftermarket parts often match or exceed OEM specifications, frequently at a lower cost. The key is quality control and manufacturing standards. Some aftermarket manufacturers actually produce components for OEM companies on the same production lines, simply without the brand markup.

When sourcing aftermarket parts, the manufacturing quality is critical. Look for parts from suppliers who clearly state their manufacturing standards and have a solid reputation in the marine industry. I've found that reputable aftermarket manufacturers often provide detailed specifications and material information that helps in selecting the right product for specific operating conditions.

One significant advantage of quality aftermarket parts is material innovation. Some specialized aftermarket manufacturers focus exclusively on cooling system components and invest heavily in material research. I've used aftermarket impellers with proprietary rubber formulations that have demonstrated excellent longevity in high-stress applications.

My advice? For standard recreational use, both quality aftermarket and OEM impellers will generally perform well. For boats used in extreme conditions or commercial applications, the specific material properties and design features become more important than whether the part is OEM or aftermarket. Always prioritize quality and correct specifications over brand name or origin.

Expert Insights for Peak Performance and Longevity

Drawing on years of experience and feedback from marine professionals, there are always more nuanced tips to enhance engine cooling and protect your vital components.

Tips from Certified Marine Technicians

I've learned from countless certified marine technicians who emphasize that while replacing the impeller is crucial, the condition of the surrounding components within the water pump housing is just as important. They often advise inspecting the wear plate and the pump housing itself for any scoring or corrosion.

One Master Mercury Technician taught me a technique I now use religiously: after removing the old impeller, run your fingertip around the inside of the pump housing in a circular motion. Any roughness, ridges, or scoring you can feel will quickly wear down even a new impeller. In these cases, replacing or refinishing the housing is necessary for proper performance.

Damage to these parts can prevent even a new impeller from sealing properly and pumping efficiently. I once rebuilt a water pump three times before realizing that a nearly invisible groove in the housing was preventing proper sealing, regardless of impeller condition.

Technicians also frequently stress the importance of using the correct marine-grade grease when reassembling. This lubricant is specifically designed to withstand water exposure and provide smooth operation, ensuring that your impeller is properly seated and protected. Standard automotive grease can wash away or break down in water, leading to premature failure.

A former Yamaha training instructor shared with me that one of the most common mistakes he saw was improper impeller installation orientation. He recommended a simple memory trick: when looking at the impeller from above (as it sits in the pump), the fins should curve counterclockwise for most outboards. This ensures they bend in the proper direction when the shaft rotates clockwise (as viewed from above) during operation.

These are the kind of best practices that experienced professionals rely on. By adopting these techniques, I've significantly improved the reliability and longevity of the cooling systems I maintain.

The Role of Regular Engine Use

It might sound counterintuitive, but using your engine regularly, within normal operating parameters, actually benefits the impeller. The constant flexing of the rubber fins keeps them pliable and prevents them from becoming brittle and sticking within the pump housing, especially during periods of inactivity.

I've observed this effect firsthand with my seasonal fishing boat. During years when I made a point to run it monthly during the off-season, the impeller remained in much better condition than during seasons when it sat untouched for months. The rubber maintained its elasticity and showed less cracking and hardening.

So, while you don't want to overwork your engine, consistent operation is generally better for the impeller's long-term health than letting the boat sit idle for months on end, provided all other maintenance is up to date. This aligns with recommendations from marine engine manufacturers like Mercury, who note in their maintenance guides that "regular operation helps maintain rubber component flexibility."

For those who can't use their boats regularly during off-seasons, I recommend at least a monthly start-up where the engine runs with proper water supply for 10-15 minutes. This brief operation isn't just good for the impeller; it benefits the entire fuel system and internal engine components as well.

Keeping Your Boat Cooling System in Top Shape

Maintaining your boat's cooling system, with a particular focus on the impeller, is not just about preventing breakdowns; it's about ensuring reliability, safety, and the longevity of your entire marine engine.

From what I've seen over two decades in this industry, proactive maintenance is always more cost-effective and less stressful than reactive repairs. The cooling system is truly the lifeblood of your engine, and the impeller is its beating heart.

To recap, the impeller is the crucial component that pumps cooling water through your engine. Its failure, often due to age, dry running, or abrasive conditions, can lead to severe engine overheating and potential stranding. Regular inspections, typically annually or every 100 hours, are paramount, and following your manufacturer's specific replacement intervals (often 1-3 years) is key.

I've seen too many enjoyable days on the water cut short by preventable cooling system failures. The modest investment in time and parts to maintain your impeller properly pales in comparison to the cost of major engine repairs or the disappointment of canceled boating plans.

Performing the replacement yourself is achievable with the right tools and a careful approach, but don't hesitate to seek professional help when needed. By avoiding dry running, using your engine regularly, and storing it properly, you can significantly extend the life of your impeller and ensure countless enjoyable hours on the water.

My final takeaway is simple: treat your boat's impeller with the respect it deserves, as it's a small part that plays an enormous role. Proactive care means fewer worries and more open water ahead. When I'm out on my boat now, I rarely think about the impeller—and that's exactly as it should be. Proper maintenance gives you the freedom to focus on enjoying your time on the water, not worrying about what might go wrong.

Sources and Further Reading

- Mercury Marine Service Manual (2022 Edition): Mercury Marine Official Service Portal

- Yamaha Outboard Owner's Manual, Technical Bulletin Y-2010-03: Yamaha Outboards Support

- American Boat & Yacht Council (ABYC) Cooling System Standards: ABYC Standards

- Marine Mechanics Institute Technical Resources: MMI Resources

- Suzuki Marine Technical Bulletins: Suzuki Marine Service

- Boating Industry Magazine (2022 Survey): Boating Industry

- Marine Engine Technicians Association: META Resources

- U.S. Coast Guard Recreational Boating Statistics: USCG Boating Safety

- Marine Equipment Trade Association Testing Reports: METS Trade

- Sierra Marine Technical Information: Sierra Marine Engineering

- JLM Marine: Factory Direct Boat Parts and Marine Supplies

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.