Avoiding Ethanol Gas Problems: Fuel Care Tips for Boaters

- Introduction to Ethanol Fuel in Boating

- What is Ethanol and Ethanol-Blended Fuel?

- Effects of Ethanol on Marine Engines

- Choosing the Right Fuel for Your Boat

- Best Practices for Fuel Handling and Storage

- Safety Tips and Common Myths about Ethanol Fuel in Boats

- Practical Tools and Resources for Boaters

- Conclusion: Navigating the Ethanol Challenge Successfully

Introduction to Ethanol Fuel in Boating

As a lifelong boater, I know the freedom that comes with hitting the water. That feeling is amplified when your engine purrs reliably, a far cry from the sputtering, engine-killing problems I've experienced firsthand. Last summer, I was caught in a dangerous situation when my friend's boat engine failed suddenly in the middle of a large lake—all because of fuel-related issues that could have been prevented with proper knowledge.

My own boating experiences have taught me that fueling is one of the most critical, yet often overlooked, aspects of boat maintenance. It seems simple enough, right? You pull up to a gas station, fill 'er up, and head out. But when it comes to ethanol-blended fuels, as commonly found at roadside retail stations, this seemingly innocuous act can actually be the root of significant trouble for your marine engine.

According to a survey by the Boat Owners Association of The United States (BoatUS), 91% of boaters who avoided serious fuel system failures specifically sought out non-ethanol gasoline whenever possible—even if it meant driving significant distances to find appropriate stations. This statistic alone speaks volumes about the importance of fuel selection.

Boater Fueling Habits and Their Consequences

It's a common sight: a truck pulling a boat trailer stopping at the nearest gas station for fuel. Most recreational boaters aren't lucky enough to have a marine fuel dock conveniently located near their launch site, so refueling at regular roadside stations becomes the default. In fact, BoatUS reports that approximately 95% of boaters fill up at roadside stations, where labeling may be unclear and the risk of misfueling is high.

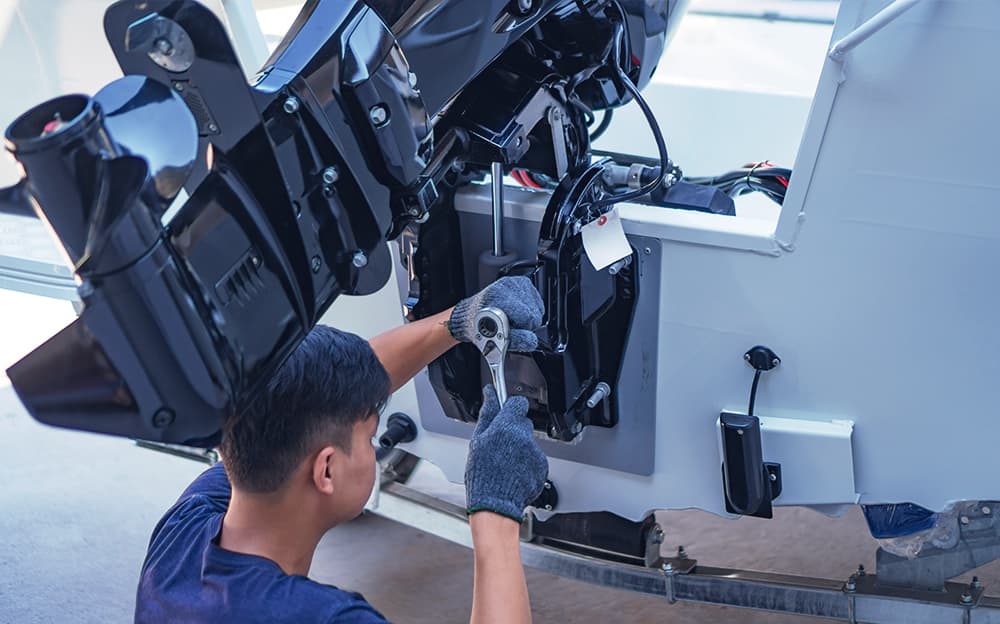

This habit, while practical, often leads to unintentional exposure to fuels that aren't ideal for marine applications. I've personally witnessed the aftermath—engines that struggle to start, mysterious power loss, and fuel systems corroded beyond repair. For boaters looking to understand components affected by ethanol fuel, reliable sources like JLM Marine's fuel filters and fuel pump parts collection provide essential replacements to maintain engine performance.

Importance of Proper Fueling

The impact of choosing the right fuel for your boat cannot be overstated. It's not just about keeping the engine running; it's about preventing costly damage, ensuring reliability on the water, and preserving the longevity of your entire marine investment.

According to data from Boating Industry, 92% of marine professionals report seeing ethanol-related engine or component damage, up from 73% just a few years earlier. More than 15% of these professionals estimate that over half of the repairs they perform are due to ethanol issues, while almost 62% attribute at least 20% of problems to ethanol use.

Using the wrong fuel can turn a relaxing day on the lake or ocean into a frustrating, expensive ordeal. I've seen repair bills exceeding $25,000 for complete engine replacements due to ethanol damage—a sobering reality that emphasizes the importance of fuel knowledge. If you do face issues with engine parts affected by fuel damage, consider utilizing JLM Marine's extensive outboard motor parts collection to source quality components for repairs.

Marine Industry Support

Fortunately, we're not alone in navigating these complex waters. Reputable marine retailers and industry organizations actively provide guidance on proper fueling practices. Organizations like the American Boat and Yacht Council (ABYC) and the National Marine Manufacturers Association (NMMA) have established guidelines and educational resources to help boaters make informed decisions about fuel.

These organizations understand the unique challenges boat owners face and offer a wealth of information, products, and support. This collaboration is vital for ensuring a positive boating experience for everyone. For more general marine parts and continuous maintenance needs, you can rely on resources from JLM Marine's home hub, where a broad variety of OEM marine parts and accessories are available.

What is Ethanol and Ethanol-Blended Fuel?

To truly understand the problems, we first need to grasp what ethanol is and why it's in our gasoline. I've found that many people have a vague idea, but understanding the specifics is key to grasping its impact on our boats.

Definition and Sources

Ethanol is essentially a type of alcohol (specifically ethyl alcohol), typically produced from the fermentation of plant materials like corn, wheat, or sugarcane. In the United States, corn is the primary source for the ethanol added to our gasoline—a fact that connects our fuel supply directly to agricultural policy.

According to the U.S. Energy Information Administration (EIA), ethanol is categorized as an oxygenate, meaning it contains oxygen atoms, which, when burned, can help gasoline burn more completely. This characteristic is central to why it's used in fuel but also creates unique challenges for marine applications.

Role in Fuel and Regulatory Background

The primary reason ethanol is blended into gasoline stems from the Renewable Fuel Standard (RFS) program, established by the Energy Policy Act of 2005 and expanded under the Energy Independence and Security Act of 2007. These regulations mandate the blending of renewable fuels, including ethanol, into transportation fuels.

As an oxygenate, ethanol is intended to reduce certain harmful emissions from vehicles like carbon monoxide and unburned hydrocarbons. It also helps to increase the octane rating of gasoline, providing a more robust fuel for automotive engines. However, what works well for cars doesn't necessarily translate to marine environments, where operating conditions and storage practices differ significantly.

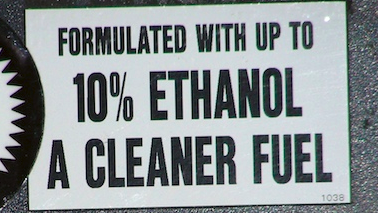

The EPA has explicitly stated that while E10 (10% ethanol) is legal for use in marine engines, E15 (15% ethanol) is not approved and is actually illegal to use in boats, motorcycles, small engines, and cars built before 2001, according to their official guidance.

Common Blends and Their Identification

You'll most commonly encounter a few different ethanol blends at fueling stations across the U.S. E10 gasoline is typically a blend containing up to 10% ethanol. According to the Renewable Fuels Association, this is the most widely distributed blend across the U.S., with over 97% of U.S. motor-fuel supply containing E10.

Further up the scale is E15 gasoline, which contains up to 15% ethanol. E15 availability is increasing across 24 states, raising concerns about misfueling risks for boaters. Then there's E85, a high blend usually reserved for flex-fuel vehicles, containing 51% to 83% ethanol.

For boats, understanding these distinctions, particularly the limit of E10, is paramount. The EPA requires that gas pumps be labeled to indicate ethanol content, but these labels can be small and easy to miss. I always make a point to look carefully at every pump before fueling my boat—a practice I strongly recommend to all boaters.

Ethanol Denaturing and Chemical Properties

A crucial point about ethanol, and one that might surprise some, is that fuel-grade ethanol is deliberately denatured. This means an additive, usually gasoline, is mixed with the pure ethanol to make it unfit for human consumption. This is a regulatory requirement to avoid taxes imposed on alcoholic beverages. So, no, you definitely cannot drink the ethanol in your boat's fuel.

Beyond this, ethanol has several chemical properties that make it problematic for marine use:

- It's hygroscopic, meaning it attracts and absorbs water from the atmosphere

- It acts as a solvent, which can dissolve deposits and even certain materials in older fuel systems

- It has lower energy content than gasoline, resulting in reduced fuel efficiency

Each of these properties contributes to the unique challenges that ethanol presents for marine engines, which we'll explore in more detail.

Effects of Ethanol on Marine Engines

Here's where things get serious. While ethanol serves a purpose in automotive fuels, its chemical properties can be downright detrimental to marine engines. My own observations and conversations with marine mechanics have revealed a consistent pattern of issues stemming from improper fuel use.

Recommended Ethanol Limits According to Manufacturers

The general consensus, backed by most marine engine manufacturers, is that 10% ethanol (E10) is the maximum acceptable blend for most marine engines. This isn't just my opinion—it's the explicit recommendation of major manufacturers like Mercury Marine, Yamaha, and Evinrude, as stated in their official warranty documentation and owner's manuals.

Anything higher, particularly E15 and E85, is considered highly harmful. Think of it like a medication: the prescribed dose is beneficial, but exceeding it can be toxic. Many older boats, in particular, have fuel systems that were never designed to handle any amount of ethanol.

According to Keith Holmes, President of CK Motorsports and a Certified Marine Technician with over 20 years of experience, "It is important that all marine engine owners follow the instructions for normal storage preparation found in the operation, maintenance and warranty manuals. Failure to follow the proper operating procedures is the number one reason why boaters have fuel issues."

Ethanol and Water Absorption: The Science Behind the Problem

One of ethanol's most problematic characteristics is its hygroscopic nature. This means it readily attracts and absorbs water from the atmosphere. The science behind this is straightforward: ethanol molecules have an oxygen-hydrogen (OH) group that forms hydrogen bonds with water molecules, drawing them into the fuel mixture.

Even small amounts of moisture can become problematic because ethanol binds with the water. This is a significant departure from pure gasoline, which tends to repel water, allowing it to sink to the bottom of the tank where it can be drained.

According to tests conducted by the U.S. Department of Energy's National Renewable Energy Laboratory (NREL), ethanol can absorb up to 0.5% water by volume before phase separation occurs. In a marine environment, where humidity is often high and temperature fluctuations are common, this water absorption accelerates significantly.

Phase Separation Explained in Detail

When ethanol-blended fuel absorbs enough water, it can reach a point where the ethanol and water mixture separates from the gasoline. This phenomenon is known as phase separation.

Here's what happens at a molecular level: As water content increases, the ethanol's attraction to water becomes stronger than its miscibility with gasoline. Eventually, the ethanol and water form a separate solution that drops to the bottom of the fuel tank due to its higher density. Instead of a uniform fuel mixture, you end up with a layer of water and ethanol at the bottom of your fuel tank, with the lighter gasoline and a lower concentration of ethanol floating above.

This is a critical failure point for marine engines, and once phase separation occurs, it cannot be reversed by adding fuel stabilizers or other additives. The only solution is to completely drain and clean the fuel system—a costly and time-consuming process. For steps in maintaining clean fuel systems and replacing compromised parts, JLM Marine’s fuel pump kits and fuel filter collections are excellent resources.

Documented Consequences for Engines

When this water-ethanol mixture is drawn from the bottom of the tank into the engine, disaster can strike. According to a technical report from BoatUS, this water-rich fuel can cause immediate engine sputtering or stalling. Over time, the corrosive nature of this mixture can lead to significant damage:

- Corrosion within fuel tanks, especially aluminum and steel tanks

- Degradation of fuel lines, gaskets, and seals

- Clogging of fuel injectors and carburetor jets

- Excessive wear on engine components, including cylinders and valves

- Complete engine failure requiring replacement

I've heard horror stories of engine failures costing tens of thousands of dollars because of this very issue. One boater from Chippewa Falls, Wisconsin, reported to BoatUS: "Ethanol deteriorated the gas tank and destroyed the engine. Gas could have ended up in the bilge, and that's life threatening."

Ethanol as a Solvent: Material Compatibility Issues

Ethanol also acts as a powerful solvent. While this might sound good for cleaning deposits, it can also break down materials within older fuel systems, such as rubber hoses and fiberglass tank linings, that weren't designed for it.

A marine technician from Texas observed: "We see issues where the Ethanol strips the paint off of the inside of the fuel cooling system… This clogs the fuel system and causes extensive repairs to be necessary."

The dislodged particles and degraded materials can then clog fuel filters, carburetors, and other critical engine parts, leading to poor performance or complete failure. It's a bit like cleaning out a dusty attic – you might get it clean, but you also create a lot of dust that needs to be managed.

A study by the U.S. Coast Guard and Mercury Marine found that certain older fiberglass fuel tanks constructed with polyester resins were particularly vulnerable to ethanol damage. The ethanol would actually dissolve portions of the resin, creating a sludge that would clog filters and damage engines. Boats built before the early 1990s are at highest risk for this issue.

For boat owners needing parts related to fuel lines and carburetors often affected by ethanol's solvent effect, browsing JLM Marine’s carburetor and carburetor repair kit collections and JLM Marine’s fuel induction parts may provide the necessary OEM quality components to keep your boat running smoothly.

Marine Engine Compatibility: Old vs. New

Modern marine engines generally have better compatibility with E10 than older models. Manufacturers have incorporated more ethanol-resistant materials into their fuel systems, including:

- Upgraded fuel lines made from ethanol-resistant materials

- Improved gasket and seal compounds

- More robust fuel tanks designed to withstand ethanol's effects

- Enhanced filtration systems to capture contaminants

However, even with newer engines, exceeding the E10 limit brings increased risk. According to the NMMA, marine engines are not designed or certified to operate on fuel containing more than 10% ethanol, regardless of age. It's always best to err on the side of caution and consult your engine's manual for specific recommendations.

What is Phase Separation and Why It's Dangerous: Real-World Examples

Imagine your fuel tank like a layered cake. With phase separation, the bottom layer is a potent mix of water and ethanol, sitting below the mostly gasoline layer. When your fuel pickup sits at the bottom of the tank, it's going to draw this highly corrosive, water-laden mixture directly into your engine.

I experienced this firsthand last season when helping a fellow boater whose engine suddenly died miles from shore. Upon inspection, we found a milky substance in the fuel filter—a telltale sign of phase separation. The repair bill exceeded $3,000, including draining the tank, replacing the fuel pump, cleaning the injectors, and replacing corroded components.

This isn't just about slightly reduced performance; it's about introducing a substance that actively attacks metal and rubber components, leading to rapid degradation. The technical term for this is "wet corrosion," and it's particularly aggressive on aluminum components commonly found in marine engines.

Recognizing the signs is key. A cloudy or milky appearance in the stored fuel is a strong indicator. You might also notice separation layers if you let a sample of fuel sit undisturbed. The most common sign, though, is unfortunately after the damage has begun: engine sputtering, loss of power, or complete failure, especially after a period of sitting idle or during a fuel system purge.

Ethanol's Impact on Fuel Efficiency and Engine Maintenance

Ethanol has lower energy density than pure gasoline, meaning you get fewer miles per gallon when using ethanol-blended fuels. According to the U.S. Department of Energy, ethanol contains approximately 33% less energy per gallon than gasoline. So, while E10 might be readily available, your boat may consume fuel faster, impacting your overall fuel costs and range on the water.

A boater from Newton, Massachusetts, reported to BoatUS: "Each percent of ethanol reduces the engine power by 1 percent. My engines will suffer irreparable harm if ethanol levels are increased."

Additionally, the solvent and corrosive properties of ethanol necessitate more frequent checks of fuel filters, lines, and seals, adding to the overall maintenance burden. I've personally seen a noticeable difference in how quickly fuel systems need attention when using E10 compared to pure gasoline. What used to be an annual filter change now requires quarterly attention—a significant increase in maintenance time and expense. For quality replacement fuel filters, consulting JLM Marine’s fuel filter selection is a smart move.

Choosing the Right Fuel for Your Boat

Navigating the fuel pump can feel like a minefield when you're a boater. Understanding your options and making the right choice is probably the single most impactful decision you can make for your engine's health.

Non-Ethanol Gasoline (E0): Benefits and Availability

This is, unequivocally, the best and safest option for virtually all marine engines. Non-ethanol gasoline (E0) provides the highest energy density, doesn't attract water, and doesn't degrade fuel system components like ethanol does.

The technical benefits are substantial:

- Higher energy content resulting in better fuel economy and performance

- No hygroscopic properties to attract water

- No risk of phase separation

- Greater stability during storage periods

- No solvent effects on fuel system components

The primary drawback? Availability. It's becoming increasingly difficult to find at standard retail gas stations, often requiring a dedicated search. According to Pure-Gas.org, a website that tracks ethanol-free fuel locations, the number of stations offering E0 has declined significantly in recent years, though they do maintain a comprehensive database of remaining locations.

In my experience, marinas and dedicated marine fuel docks are your best bet for finding E0, though they typically charge a premium. The price difference can be significant—often 50 cents to a dollar more per gallon—but I consider this an investment in my engine's longevity rather than an expense.

E10 Gasoline: When and How to Use Safely

E10 gasoline is the most common blend found at roadside stations. For many modern boats that are designed to tolerate it, E10 is often considered acceptable for regular use. According to the NMMA, most marine engines manufactured after 1990 can use E10 without immediate issues, provided proper maintenance practices are followed.

However, it's crucial to remember that even 10% ethanol means your fuel is hygroscopic and a potential solvent. My personal philosophy leans towards treating E10 with caution, especially for extended storage or in humid environments.

If E10 is your only option, these precautions are essential:

- Never store E10 in your boat for more than 90 days without treatment

- Always use a marine-specific fuel stabilizer designed for ethanol blends

- Keep your tank either completely full (to minimize condensation space) or nearly empty (if planning to refill with fresh fuel before next use)

- Install a quality water-separating fuel filter and check it frequently

- Consider adding an ethanol fuel treatment specifically designed to combat phase separation

Avoiding E15 and Higher: Legal and Technical Reasons

I cannot stress this enough: avoid E15 and higher ethanol blends like the plague when fueling your boat. The U.S. Environmental Protection Agency (EPA) has explicitly stated that E15 is not approved for use in marine engines, and the consequences of misfueling with anything above E10 are severe, including catastrophic engine damage and the voiding of warranties.

In fact, the EPA has determined that using E15 in marine engines violates the Clean Air Act and federal law. The warning label on E15 pumps states clearly: "ATTENTION: E15 UP TO 15% ETHANOL. USE ONLY IN: 2001 AND NEWER PASSENGER VEHICLES, FLEX-FUEL VEHICLES. DON'T USE IN OTHER VEHICLES, BOATS, OR GASOLINE-POWERED EQUIPMENT."

Despite this warning, the risk of accidental misfueling is significant. A survey by the Outdoor Power Equipment Institute found that more than 60% of Americans are not paying attention to the fuel they use, creating a dangerous situation for those trailering their vessels to gas stations.

Consulting Manuals and Experts: Manufacturer-Specific Guidance

The absolute best guidance comes directly from your boat and engine manufacturer. Always consult your owner's manual for specific recommendations regarding ethanol fuel blends. Many manufacturers provide detailed fuel requirements and explicit warnings about using higher ethanol blends.

For example, Mercury Marine's owner's manuals state explicitly: "Fuel containing more than 10% ethanol is not recommended for use in Mercury Marine engines and may void the warranty." Similar language appears in documentation from Yamaha, Suzuki, Honda, and other major marine engine manufacturers.

Beyond that, speaking with a trusted marine mechanic is invaluable. They see the aftermath of incorrect fueling day in and day out and can offer practical advice tailored to your specific engine and boating conditions. I make a point to discuss fuel choices with my mechanic during annual service—a conversation that has saved me from costly mistakes.

Availability and Cost Considerations: Planning Your Fueling Strategy

The reality is that finding ethanol-free gas often requires extra effort and sometimes a higher price tag. While the initial cost might be slightly more, I firmly believe the cost savings in avoided repairs and the peace of mind it provides are well worth it. Convenience can sometimes be a costly habit when it comes to boat fuel.

To manage this challenge, I recommend:

- Planning your boating trips with fuel stops in mind, using resources like Pure-Gas.org to locate ethanol-free stations

- When trailering, fueling up at known ethanol-free locations even if it means a slight detour

- For boats kept in marinas, using the marina's fuel dock when possible, even with the premium pricing

- Calculating the true cost of ethanol fuel by factoring in reduced fuel efficiency and potential repair costs

I personally keep a small notebook documenting my fuel purchases, including location, type, and how the engine performed afterward. This practice has helped me identify the best fueling options in my area and avoid problematic stations.

Best Practices for Fuel Handling and Storage

Proper fuel handling and storage are where you can really take control and mitigate the risks associated with ethanol. It's about being proactive rather than reactive. Based on my experiences and research, these practices are non-negotiable.

Where to Buy Ethanol-Free Fuel: Finding Reliable Sources

I've become quite adept at locating ethanol-free fuel stations. Resources like Pure-Gas.org are incredibly helpful for finding stations that carry ethanol-free gasoline (E0). These stations are often found at marinas or specific fuel retailers that cater to a clientele that demands higher quality fuel.

In my area, I've identified three reliable sources:

- A marina about 20 miles from my home that consistently carries E0

- A small, independent gas station that specializes in fuel for classic cars and boats

- A regional chain that offers ethanol-free premium at select locations

While it might mean a slightly longer drive, I consider it a crucial step in my fueling routine. The small inconvenience is far outweighed by the benefits to my engine and the reduced maintenance headaches.

Additionally, some boaters I know purchase fuel in bulk using approved portable tanks during the offseason when they find a good source, storing it properly with stabilizer for use during the boating season. This approach requires careful attention to fuel storage best practices but can ensure a reliable supply.

Fuel Labeling Challenges: Reading and Understanding Pump Labels

The increasing prevalence of E15 at roadside stations poses a significant risk. According to BoatUS, E15 availability is expanding across 24 states, raising the likelihood of accidental misfueling.

Blender pumps, which can dispense various blends, are particularly confusing. These pumps may offer multiple fuel grades with different ethanol contents, sometimes from the same nozzle. Always look for clear labeling on the pump, which is required by federal law.

The EPA mandates that E15 pumps display a black and orange label stating the ethanol content and usage restrictions. However, these labels can be small and easily overlooked in the rush to fuel up. If there's any doubt, don't guess; don't buy. It's far better to find another station than to risk misfueling.

I've learned to be vigilant and even ask the attendant if I'm unsure, though often they're not aware of the specifics themselves. When in doubt, I've found that most station managers can provide a more definitive answer about their fuel composition or direct you to documentation that details the ethanol content.

Storing Fuel Safely: Tank Management and Stabilization

When it comes to boat storage, especially over the off-season, fuel management is paramount. A survey by Boating Industry found that more than 90% of marine service professionals recommend specific fuel storage practices to prevent ethanol-related issues.

Keeping your boat's fuel tank as full as possible is a critical step. This minimizes the amount of air space in the tank, which directly reduces the potential for moisture to condense and enter the fuel. According to Mercury Marine's technical documentation, a full tank leaves less room for air, which contains moisture that can be absorbed by the ethanol in the fuel.

I've also found that using a high-quality marine fuel stabilizer specifically designed for ethanol blends makes a noticeable difference. These additives help to combat the adverse effects of ethanol, like phase separation and oxidation. The key is to add the stabilizer when the fuel is fresh, not after it has already begun to degrade.

For portable tanks, the best practice is to either drain them completely before storage or refill them with fresh, stabilized fuel right before the next use. I personally prefer to drain my portable tanks completely and then run the engine dry to clear the fuel system. This approach has served me well over many seasons.

Routine Fuel System Maintenance: Filters, Water Separators, and Inspections

Regular maintenance is your best defense against ethanol-related problems. According to a study by the American Boat and Yacht Council (ABYC), properly maintained fuel systems show significantly fewer issues with ethanol fuels compared to neglected systems.

This includes frequently checking and replacing fuel filters. The ABYC recommends inspecting filters at least every 50 hours of operation when using E10, and more frequently in humid environments. Water separators, if you have them, should be inspected and drained regularly. Many marine professionals recommend installing a clear bowl water separator, which allows you to visually inspect for water contamination without disassembly.

Checking fuel lines and connections for any signs of swelling, cracking, or degradation is also vital. Pay particular attention to rubber components, which are most susceptible to ethanol damage. Modern ethanol-resistant fuel lines are typically labeled "J1527" to indicate their compatibility with ethanol blends.

Proactive checks can catch minor issues before they become major, catastrophic failures. I make it a habit to inspect my entire fuel system at the beginning of each season and periodically throughout the year. This practice has helped me identify and address potential problems before they left me stranded on the water.

Transitioning from Non-Ethanol to Ethanol Fuel: Adaptation Strategies

If you've been using ethanol-free fuel and need to switch to E10, it's wise to do so strategically. The transition can be challenging for fuel systems that have become accustomed to non-ethanol gasoline, as the ethanol may dissolve built-up deposits and overwhelm filters.

Fill up with E10 and then add a suitable fuel stabilizer. Run the engine for a while to ensure the stabilized fuel circulates throughout the entire fuel system, from the tank to the injectors. This helps prepare the system for the ethanol blend and offers some protection.

I recommend replacing fuel filters shortly after the transition, as they may quickly become clogged with dissolved deposits. Also, be particularly vigilant about checking for leaks or signs of degradation in the weeks following the switch.

One boater I know makes a practice of alternating between E0 and E10 when necessary, rather than making a complete switch. While not ideal, this approach can help minimize the shock to older fuel systems when ethanol-free fuel isn't consistently available.

Using Fuel Additives with Ethanol Fuels: What Works and What Doesn't

I'm often asked about fuel additives. While they aren't a magic bullet to fix phase separation once it has occurred, the right additives can certainly help manage ethanol's negative effects.

Look for stabilizers designed for marine use and specifically formulated to counter ethanol's impact, such as those that battle water absorption and boost fuel stability. Products containing corrosion inhibitors and antioxidants are particularly beneficial for marine engines.

Many people believe that simply adding any stabilizer will fix everything, but I've learned that the type of additive matters. Some might even introduce more alcohol through their formulation, which is the last thing you want. Always research the product and understand its ingredients.

According to a study published in the Journal of the American Boat and Yacht Council, fuel stabilizers containing water controllers and corrosion inhibitors showed the best results in preventing ethanol-related fuel degradation during storage periods. However, the same study found that no additive could reverse phase separation once it occurred—reinforcing the importance of prevention.

My personal approach is to use a marine-specific stabilizer with each fill-up during the season, doubling the dose when preparing for storage longer than 30 days. This practice has kept my fuel system trouble-free through multiple seasons.

Winterizing Your Boat Fuel System: Seasonal Storage Best Practices

When winter looms, proper fuel system preparation is essential. As I mentioned, topping off the tank and adding a good quality ethanol-specific fuel stabilizer is crucial. The full tank minimizes airspace where condensation can form, while the stabilizer helps prevent fuel degradation during the idle months.

After adding the stabilized fuel, run the engine for a sufficient time to ensure the stabilized fuel has circulated through the entire fuel system—carburetor, fuel lines, and injectors. The American Boat and Yacht Council recommends running the engine for at least 15 minutes to ensure complete circulation. This ensures all components are coated with the protective mixture, minimizing the risk of corrosion and degradation during the cold, dormant months.

Some old-school advice suggests draining the tank, but honestly, with modern E10, leaving it full and treated is generally preferred to prevent moisture ingress. Empty tanks can accumulate condensation, which will cause problems when you refill in the spring.

I also recommend changing the fuel filter before storage and again at the start of the new season. This practice ensures you're beginning each season with clean, uncontaminated fuel flowing through your system.

For boats with portable fuel tanks, I disconnect them and store them in a cool, dry place away from direct sunlight and extreme temperature fluctuations. This simple step can significantly reduce the risk of fuel degradation during storage.

Safety Tips and Common Myths about Ethanol Fuel in Boats

Beyond just avoiding damage, understanding the safety implications and debunking common myths surrounding ethanol fuel in boats is crucial for responsible boating.

Misfueling Risks: Safety and Legal Implications

The danger of accidentally filling your boat with E15, or even higher ethanol blends, cannot be overstated. As I've discussed, these blends can severely damage your engine and fuel system. More critically, a sudden engine failure on the water can be a life-threatening situation, especially if you're far from shore or in rough conditions.

The EPA has made it illegal to use E15 in marine engines, and doing so may void your warranty according to most manufacturer policies. This isn't just regulatory overreach—it's based on extensive testing showing the harmful effects of higher ethanol blends on marine engines.

From a safety perspective, engine failure in open water creates numerous hazards:

- Loss of maneuverability, especially in strong currents or winds

- Inability to avoid collisions with other vessels or fixed objects

- Difficulty returning to harbor or dock, potentially requiring rescue

- In extreme cases, being stranded in harsh weather conditions

I always double-check the pump label and have even taken to carrying a small fuel tester that can verify ethanol content when I'm unsure. This simple precaution has prevented potentially dangerous situations on multiple occasions.

Myth Busting: Separating Fact from Fiction

Let's tackle a few common myths I hear about ethanol fuel in boats:

Myth: "Additives can fix phase separation." Fact: Once phase separation occurs, the water-ethanol mixture has settled out. According to research by Mercury Marine and the ABYC, additives can help prevent it, but they can't magically reintegrate a separated fuel. The best approach is prevention, as the technical chemical bonds that break during phase separation cannot be restored without specialized equipment.

Myth: "Ethanol burns cleaner, so it's better for the environment in my boat." Fact: While ethanol can improve emissions in automotive engines under controlled conditions, its impact on marine engines is complex. A study by the U.S. Department of Energy found that ethanol's emissions benefits in marine applications were often negated by decreased efficiency and increased fuel consumption. The environmental benefit is often further diminished by the damage it causes, leading to more repairs and potential spills from engine failure.

Myth: "Any gasoline stabilizer is fine." Fact: As I've mentioned, not all stabilizers are created equal. Some contain alcohols similar to ethanol, which can exacerbate the problem. The ABYC specifically recommends stabilizers formulated for marine use with ethanol fuels. These products typically contain different chemical compounds designed to address ethanol's unique challenges in marine environments.

Myth: "Newer boats don't have ethanol problems." Fact: While modern boats are better equipped to handle E10, they are still not designed for higher ethanol blends. According to NMMA testing, even the newest marine engines show performance issues and potential long-term damage when run on E15 or higher blends. The improvements in newer boats relate to material compatibility with E10, not a complete solution to ethanol's fundamental chemical properties.

Fact: Ethanol's Role in Modern Fuels

The reality is that ethanol is mandated in fuels for emissions control purposes in automobiles under the Renewable Fuel Standard (RFS). According to the EPA, the RFS program was created under the Energy Policy Act of 2005 and expanded under the Energy Independence and Security Act of 2007, requiring renewable fuel to be blended into transportation fuel in increasing amounts each year.

The challenge for the marine industry is that boat engines often operate at higher, sustained loads and RPMs compared to cars, making them more susceptible to the adverse effects of ethanol. Marine engines also experience unique conditions including:

- Extended periods of non-use (seasonal storage)

- Exposure to high humidity and water environments

- Constant vibration that can agitate fuel and accelerate phase separation

- Open venting systems that allow more moisture to enter fuel tanks

The industry is striving for a balance, but for now, boaters must remain vigilant. Organizations like the NMMA continue to advocate for policy considerations specific to marine applications, including potential exemptions from higher ethanol requirements.

Warranty Considerations: Protecting Your Investment

This is a big one for me. Many marine engine manufacturers explicitly state that using fuels with more than 10% ethanol, or failing to follow their specific fuel recommendations, will void your engine warranty.

For example, Mercury Marine's warranty documentation states: "Damage caused by using gasoline containing more than 10% ethanol, gasoline containing methanol, gasoline/methanol blends, or gasoline with an octane rating less than 87 octane, or leaded fuel is not considered a defect in material or workmanship and is not covered under the limited warranty."

Similar language appears in warranty policies from Yamaha, Suzuki, Honda, and virtually all major marine engine manufacturers. If you experience an ethanol-related issue and the manufacturer discovers you've used improper fuel, you could be stuck with the entire repair bill.

I always keep my fuel receipts and note the ethanol content in my boat's maintenance log. This documentation can be invaluable if warranty issues arise, providing evidence that you've followed the manufacturer's recommendations. It's a simple practice that could save thousands in the event of a dispute.

Practical Tools and Resources for Boaters

Fortunately, we have excellent tools and resources at our disposal to make informed decisions about ethanol fuel.

Locating Ethanol-Free Fuel Stations: Apps and Websites

As mentioned, resources like Pure-Gas.org are invaluable for finding stations that carry ethanol-free gasoline (E0). It's a simple website where you can enter your location and see nearby options. They maintain a database of over 15,000 stations nationwide offering ethanol-free fuel.

Mobile apps like "Ethanol-Free Gas Finder" also provide on-the-go information about station locations. These apps often include user reviews and updated information about availability and pricing, making them particularly useful for boaters traveling to unfamiliar areas.

I also keep a mental map of reliable marinas in my regular cruising areas. It's worth taking a few minutes to plan your fueling stops around availability of the right fuel. Most marinas and dedicated marine fuel docks carry ethanol-free gasoline, though typically at a premium price.

Marine Retailers and Education Resources

Trusted marine retailers are fantastic sources of information and provide products specifically designed for marine use. They carry high-quality fuel additives, replacement filters, and often have knowledgeable staff who can answer your questions.

Organizations like the ABYC, NMMA, and BoatUS also offer educational resources about proper fuel management. These include:

- Technical bulletins detailing best practices

- Online courses about boat maintenance, including fuel system care

- Publications with updated information about fuel regulations and technologies

I've often found advice and product recommendations from these retailers and organizations to be excellent. They base their guidance on technical research and real-world experience across thousands of boats, providing a valuable perspective beyond individual anecdotes.

For purchasing genuine parts and accessories essential for ongoing marine engine maintenance and repair, I rely on the comprehensive selections available at JLM Marine's hub.

Fuel Testing and Monitoring Tools: Taking Control

For the truly proactive boater, there are tools available to test your fuel quality. While not as common as engine diagnostic tools, certain kits can help you detect the presence of water or confirm the ethanol content of your fuel.

Simple ethanol test kits use a graduated cylinder and a water-reactive solution to determine the percentage of ethanol in your fuel. These tests typically cost under $20 and can provide peace of mind when fueling at unfamiliar stations.

Water detection pastes and electronic moisture meters can alert you to water contamination before it causes damage. These tools are particularly valuable for boats that sit unused for extended periods, as they can help identify phase separation early.

Regularly checking your fuel filters for any unusual deposits or signs of degradation can also provide early warnings of fuel system issues. I make a habit of inspecting my filter each time I remove it for replacement, looking for signs of contamination, unusual coloration, or debris that might indicate developing problems.

Conclusion: Navigating the Ethanol Challenge Successfully

Ethanol in marine fuel presents significant challenges, but with the right knowledge and practices, these challenges can be effectively managed. As a boater who's experienced both the frustration of ethanol-related problems and the satisfaction of preventing them, I can attest that a proactive approach makes all the difference.

Key Takeaways for Boaters

- Use the right fuel: Non-ethanol (E0) is best; E10 is acceptable if used carefully; avoid E15+ completely

- Check labels carefully: Don't assume all gas is the same; verify ethanol content every time

- Plan your fueling strategy: Know where to find appropriate fuel using resources like Pure-Gas.org

- Use proper storage practices: Keep tanks full with stabilized fuel during off-seasons

- Maintain your fuel system: Replace filters regularly and inspect components for degradation

- Document everything: Keep records of fuel purchases and maintenance for warranty protection

These points highlight that while ethanol is a prevalent component in automotive fuel, its complexities demand careful consideration and proactive management by every boat owner. By staying informed, utilizing the right resources, and adhering to best practices, we can keep our engines running smoothly and enjoy our time on the water without unwanted surprises.

So, what's my final take on ethanol? It's a necessary evil for many cars, but for boats, it's more of a liability. Prioritizing ethanol-free fuel whenever possible, meticulously using the right stabilizers, and maintaining a vigilant approach to fuel handling and storage are not just good ideas; they are essential practices for any serious boater who values the longevity and performance of their marine engine. Make the smart choices today to avoid the costly repairs of tomorrow.

Sources:

- Pure-Gas.org - Ethanol-Free Gas Stations

- BoatUS: Ethanol Mandate Frustrates Boaters

- U.S. Environmental Protection Agency - Fuels Registration, Reporting, and Compliance Help

- Boating Industry: Ethanol Still a Significant Challenge

- American Boat and Yacht Council (ABYC) Technical Information

- Power Implements: Navigating Ethanol Fuel - Tips for Boat Owners

- Bell Performance: The Damaging Effects of Ethanol in Your Boat's Fuel

- West Marine: Busting Ethanol Fuel Myths

- Thunder Marine: ETHANOL FUEL IN BOATS: Myths, Facts and Solutions

For further details and to explore parts critical for your marine engine maintenance, visit the JLM Marine hub.

Leave a comment

Please note, comments need to be approved before they are published.