Saltwater Use and Overheating: Prevention Tips

- How Saltwater Clogs Your Cooling System

- Check Your Impeller First

- Flushing: The One Step That Saves Motors

- Thermostat Failures in Saltwater

- Corrosion and Galvanic Issues

- Strainers and Intake Screens

- What to Do When You Overheat on the Water

- Heat and Load Management

- Preventing Corrosion on Commercial and Fishing Boats

- Saltwater Aquarium Overheating (Brief Overview)

- OEM vs Aftermarket Cooling Parts

- Pro Tip

After twenty years wrenching on outboards, I can tell you saltwater and heat are the two biggest killers of marine engines. They work together to wreck cooling systems faster than most people realize. If you run in salt and ignore your cooling system, you're going to overheat. It's not if, it's when.

How Saltwater Clogs Your Cooling System

Saltwater carries more than just salt. You've got sand, shell fragments, algae, and all kinds of growth that gets sucked into your raw water intake. When that debris sits in your cooling passages after shutdown, it hardens. Salt crystals form inside the block, around the thermostat housing, and especially in the small passages of the water pump housing.

I've pulled thermostats that were completely encased in white crusty buildup. The thermostat itself might've been fine, but it couldn't open because salt locked it in place. Marine Diesel Specialists lists clogged intakes and failed impellers as the top two overheating causes in saltwater boats, and that matches what we see on the bench every single day.

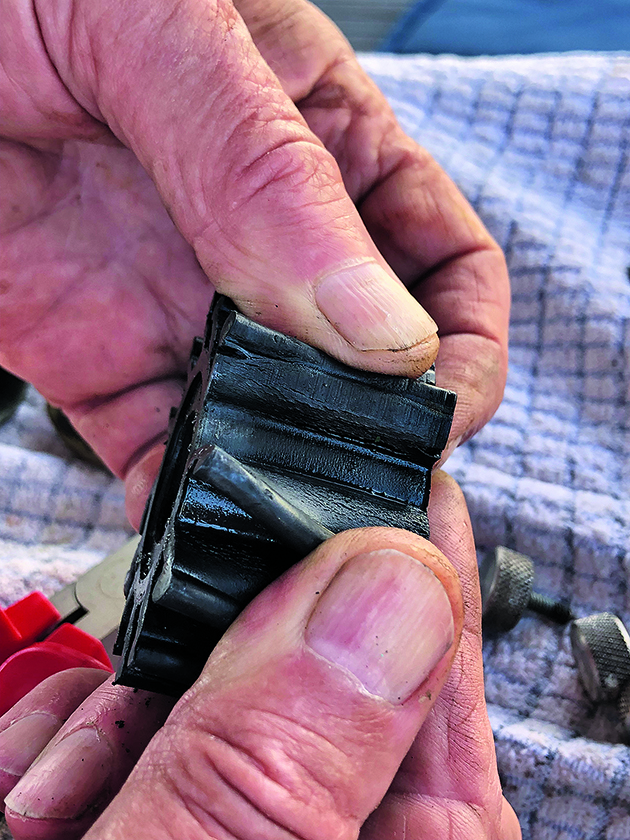

Check Your Impeller First

The impeller is your first suspect when a saltwater motor runs hot. Rubber impeller vanes get chewed up by sand and debris. They crack from heat cycling. Sometimes a piece breaks off and blocks a passage downstream.

Here's what to look for: weak pee stream at idle that barely improves with throttle. That usually means the impeller is worn but not completely gone. If you get no stream at all, the impeller might be shredded or the tube itself is blocked.

Pull the lower unit, yank the pump housing cover (usually four to six bolts), and inspect every vane. If any vane has a chunk missing, find that chunk. It's stuck somewhere in your system. Replace the impeller, the gasket, and the wear plate if it's scored. Don't reuse old hardware. For quality parts and replacements, check out the water pump impeller kits at JLM Marine.

Use a pick or small screwdriver to clear the pee hole tube. I've found barnacle shells, plastic bits, and once an entire small crab jammed in there.

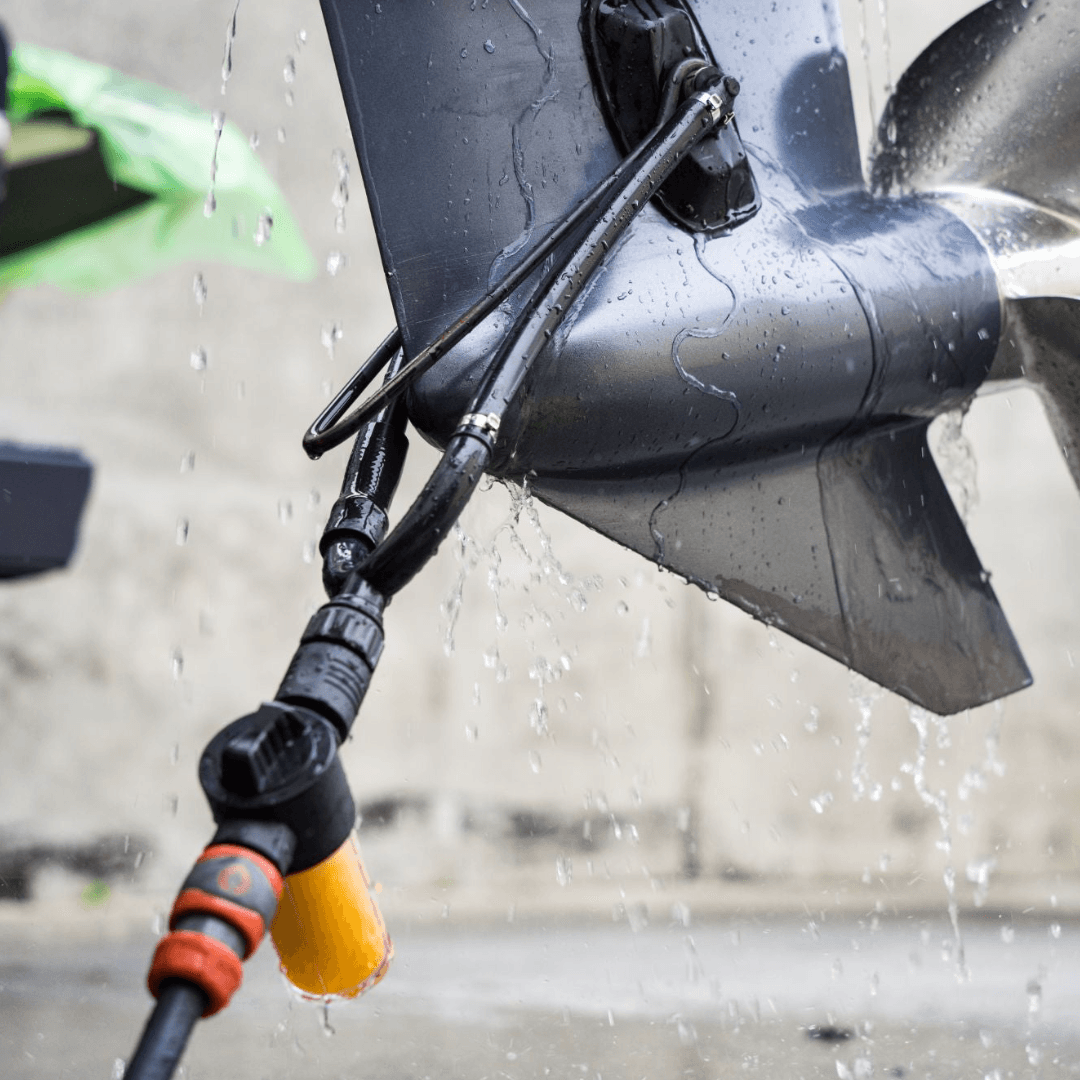

Flushing: The One Step That Saves Motors

Flush your motor with fresh water after every saltwater run. Not once a week. Every single time.

For outboards, use flush muffs on the lower unit intakes or connect a hose to the built-in flush port if your motor has one. Run the engine at idle for at least ten minutes. Don't just run water through it cold—fire it up. You need flow through the thermostat and all the internal passages, and the thermostat only opens when the engine is at temperature.

If you trailer your boat, flush before you pull it out and again at home. According to Jette K Watersports, flushing is the number one maintenance step to prevent salt buildup and overheating in Florida's brackish coastal waters, and that advice applies anywhere you run in salt.

For sterndrives and inboards with raw water cooling, close the seacock, disconnect the raw water intake hose, and stick it in a bucket of fresh water. Run the motor and keep the bucket topped off. Ten minutes minimum. Some guys run a weak vinegar solution (5% acetic acid) once a month to dissolve scale, but fresh water after every trip is the baseline.

Thermostat Failures in Saltwater

Thermostats get seized by salt corrosion or debris. When a thermostat sticks closed, coolant can't circulate and your motor cooks. When it sticks open, the motor runs too cold and you get poor fuel economy, but that's the less common failure.

A thermostat replacement is simple. It's usually under a housing on top of the block, held by two bolts. Pull it, drop it in boiling water, and watch if it opens. If it doesn't open by around 140-160°F (depending on your motor's spec), toss it. For detailed steps on handling thermostat issues, see our guide on thermostat maintenance to keep your outboard running cool.

Here's a trick: before you reinstall the housing, pour a little fresh water through the passage and see if it drains clean. If it comes out rust-colored or gritty, you've got buildup upstream. Flush it harder or pull the block drain plugs and backflush with a hose and some pressure.

We stock thermostats for most outboards. OEM thermostats work fine, but you're paying extra for the manufacturer's box. Quality aftermarket thermostats from suppliers like JLM Marine use the same spec springs and open at the same temperature, and they cost about half. Just don't buy the no-name $8 ones off random sellers—those often use stiffer springs or bad wax elements and either don't open or open late.

Corrosion and Galvanic Issues

Saltwater is conductive. If you've got dissimilar metals underwater—aluminum lower unit, stainless steel prop, brass fittings—you've created a battery. Current flows, and the least noble metal (usually aluminum) corrodes.

West Marine's guide on galvanic corrosion explains that sacrificial anodes (zincs in saltwater, aluminum in brackish) need replacement when they're about 50% gone. We see people run zincs down to nubs, then wonder why their lower unit casting looks like Swiss cheese.

Check your anodes every month if you're in the water full-time. Replace them when half-consumed. If they're disappearing in a few weeks, you've got a stray current problem—usually a bonding issue or a shore power ground fault. Use a multimeter to check for voltage between your drive and a ground in the water. Anything over about 0.6V means you're eating metal.

For outboards, the main anode is on the cavitation plate. Sterndrive guys also need to inspect the trim tab anodes and sometimes the ones inside the raw water passages. Replace them all at the same time so you're not mixing old and new metals.

BoatUS also notes that bonding all underwater metals together and running a single sacrificial anode reduces mixed-metal corrosion, which indirectly prevents overheating by keeping water passages clear of corrosion-induced blockages.

Strainers and Intake Screens

Raw water strainers (on inboards and some larger outboards) catch debris before it hits the pump. If you've got one, check it weekly in saltwater. We've pulled out seaweed, plastic bags, jellyfish, and mud.

Clean the strainer basket, and while it's off, inspect the bowl gasket. If it's hard or cracked, replace it. A slow leak here will let air into the system and cause cavitation at the pump, which kills flow and causes overheating.

Outboards have intake screens on the lower unit. Pull the motor and hit those screens with a hose and a soft brush. Don't skip this. I've seen screens so clogged the motor could barely pull water at idle.

What to Do When You Overheat on the Water

If your temp alarm goes off or you see steam, shut down immediately. Continuing to run will warp the head or seize the powerhead.

Let it cool for at least 20 minutes. Check the pee stream—if there's no stream, you've lost water flow. Check for a wrapped fishing line around the prop or intake. Look for a split or disconnected hose.

If the pee stream is strong and everything looks normal, the thermostat might've stuck or you've got an internal blockage. Limp back at low RPM and get it to a lift. According to Jette K Watersports, running at varied speeds and taking cooling breaks reduces engine load in hot conditions, but don't push it if the alarm is screaming.

Don't pour cold water on a hot block. You'll crack the casting. Let it cool naturally.

Heat and Load Management

Running wide-open throttle for hours in 95°F summer heat puts maximum load on your cooling system. The hotter the ambient air and water, the less efficient your heat exchanger (if you have one) or your raw water cooling becomes.

Moto Nation of Memphis recommends taking short breaks during long runs in high heat to allow the system to catch up. This is especially true if you're running a heavily loaded boat or towing skiers in shallow, warm water where intake temps can hit 85°F or more.

If you frequently run hard in hot conditions, consider upgrading to a larger capacity water pump or adding a secondary raw water pickup if your hull allows it. Some guys running tournament boats in Florida will add an auxiliary pump to increase flow during wide-open runs. Find reliable components like water pump kits at JLM Marine to improve your cooling system performance.

Preventing Corrosion on Commercial and Fishing Boats

If you're running a commercial rig or spending weeks at a time in saltwater, you need a more aggressive corrosion program. ZRC Worldwide recommends applying cold galvanizing spray annually to exposed steel and aluminum on fishing boats that operate in the Atlantic or Pacific. This adds a sacrificial zinc-rich coating that corrodes before your base metal does.

We also see commercial operators who pull and soak their raw water pumps in a citric acid solution (about 10% concentration) once a season to dissolve any scale. Disassemble the pump, soak the housing and impeller plate for a few hours, scrub with a nylon brush, rinse, and reassemble. Don't soak rubber or plastic parts in acid—just the metal castings.

Keep all electrical connections above the bilge. Saltwater in the bilge will wick up into wire bundles and corrode terminals, which increases resistance and can cause electrical components (like fuel pumps or trim motors) to overheat and fail.

Saltwater Aquarium Overheating (Brief Overview)

Saltwater aquariums overheat mainly from environmental factors—room temperature, direct sunlight, and heat from lighting. According to RateMyFishTank, the safe range for most reef tanks is 76-82°F. Above that, you risk coral bleaching and fish stress from reduced oxygen solubility.

Use fans blowing across the surface to increase evaporative cooling. This can drop temps by 2-4°F depending on humidity. If you're in a hot climate like Southern California or Florida, you may need a chiller. Size the chiller to your tank volume and heat load—undersizing means it runs constantly and burns out.

Reduce lighting duration in summer. Metal halide and high-output T5 fixtures dump a lot of heat into the water. Switching to LED can cut heat by half.

Keep heaters on a controller with a backup thermometer. We've seen stuck-on heaters cook entire tanks. Set the controller to cut power at 2°F above your target, and use a separate visual thermometer to cross-check.

Larger tanks fluctuate slower than nanos. A 100-gallon system might drift 1°F over a hot day, while a 10-gallon can swing 5°F in an hour if it's near a window.

OEM vs Aftermarket Cooling Parts

OEM water pump kits, impellers, and thermostats are good, but you're paying a premium. The box says "Yamaha" or "Mercury," but often it's made by the same supplier that produces aftermarket parts.

Cheap aftermarket is a different story. We've seen $12 impeller kits where the rubber is too hard, the vanes are undersized, and the housing gasket doesn't seal. You'll be pulling the lower unit again in three months.

The smart choice is reputable aftermarket from suppliers like JLM Marine. You get factory-spec materials and fitment without the dealership markup. We ship these kits globally—sent one to a guy in Australia last week who had a seized impeller on a Suzuki 90. It fit perfectly, cost half of OEM, and he was back on the water in a day. Explore our wide selection of cooling system parts at JLM Marine for trusted replacement options.

For critical parts like thermostats and impellers, always match the part number exactly. Engines often have mid-year changes, and the wrong impeller can have fewer vanes or a different height, which kills flow and causes overheating.

Pro Tip

Pull your raw water pump impeller every 100 hours or once a season, whichever comes first. Even if it looks okay, replace it. Soak the pump housing in white vinegar for an hour to dissolve any salt, rinse it clean, and put in a new impeller with fresh gaskets. That one step prevents 90% of the saltwater overheating calls we get.

For more high-quality marine engine parts and accessories that help prevent issues like those discussed, visit JLM Marine, your source for premium boat components direct from the factory.

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.