Outboard Lower Unit Repair: Salvaging Impeller Shafts & Identifying Short vs. Long Shafts

When you pull the lower unit and find a seized impeller shaft or realize you've been running the wrong shaft length for two seasons, you're looking at real money and downtime. I've spent twenty years wrenching on these things, and both problems come up more often than they should.

Salvaging Impeller Shafts: When to Save and When to Replace

The impeller shaft—that's your drive shaft running through the water pump housing—takes a beating. Salt, sand, and neglect will lock it up tight or score the splines until they're useless. Before you order a new shaft, spend ten minutes checking if you can salvage it.

Pull and Inspect the Shaft

Yank the water pump housing off. Most units use six bolts around the perimeter. Once the housing's clear, the impeller and key slide off the shaft. Now you can see what you're dealing with.

Check for straightness first. Roll the shaft on a flat surface—your workbench or a piece of glass. Any wobble means it's bent. Don't bother trying to straighten it; you'll never get it true enough, and it'll vibrate and destroy your new seals. A dial indicator works if you want to be precise, but the roll test catches anything over a few thousandths.

Inspect the splines next. Look for gouges, rounded edges, or cracks. Minor surface rust? That's fine—hit it with some fine emery cloth or Scotch-Brite. Deep grooves where the impeller key seats? That shaft's done. The impeller won't lock properly, and you'll lose your water pump at the worst possible time.

Check the bearing journals. If the shaft runs rough in the housing bearing or you see scoring, it's trash. New seals won't fix that—they'll just leak again in a month.

Cleaning and Prepping for Reuse

If the shaft passes inspection, soak it in penetrating oil. I use PB Blaster and let it sit overnight. Brush off any corrosion with a wire wheel—don't go heavy on good metal, just clean it.

Polish the seal surfaces with 400-grit wet-dry sandpaper. The rubber lip seals need smooth metal to bite on. Any pitting or roughness will weep oil or suck air.

Before reinstall, coat the splines with soapy water or impeller grease. Never force a dry impeller onto the shaft. You'll tear the vanes, and they'll fail within hours. Ask me how I know.

When Salvage Isn't Worth It

If you see any of this, order a new shaft:

- Bent more than 0.005 inches

- Splines worn down or cracked

- Deep scoring in the seal area that you can catch with your fingernail

- Corrosion pitting through the surface

A new shaft runs $60 to $200 depending on your motor. That's cheap compared to a tow bill or cooking your powerhead because the pump quit.

Tyler Holland from Outboard Specialty Tools shows full teardowns where he salvages shafts by soaking parts in penetrating oil and brushing clean before inspecting gears and installing new seals. He's clear: "at this point if I'm doing seals I want to get in here inspect gears inspect Clutch Dog inspect pinion make sure we're got everything in good shape."

Tools You Actually Need

- Socket set (most lower unit fasteners are 10mm, 12mm, or 1/2-inch)

- Seal driver set or a deep socket that matches your seal OD

- Fine emery cloth or Scotch-Brite pads

- Penetrating oil

- Dial indicator (optional, but useful)

- Wire brush or wheel

- Impeller grease or dish soap

For sourcing high-quality parts like impellers or seals, it's often best to explore our direct outboard motor parts collection at JLM Marine, where you can find OEM-quality components without dealership markup.

Measuring and Identifying Short vs. Long Shafts

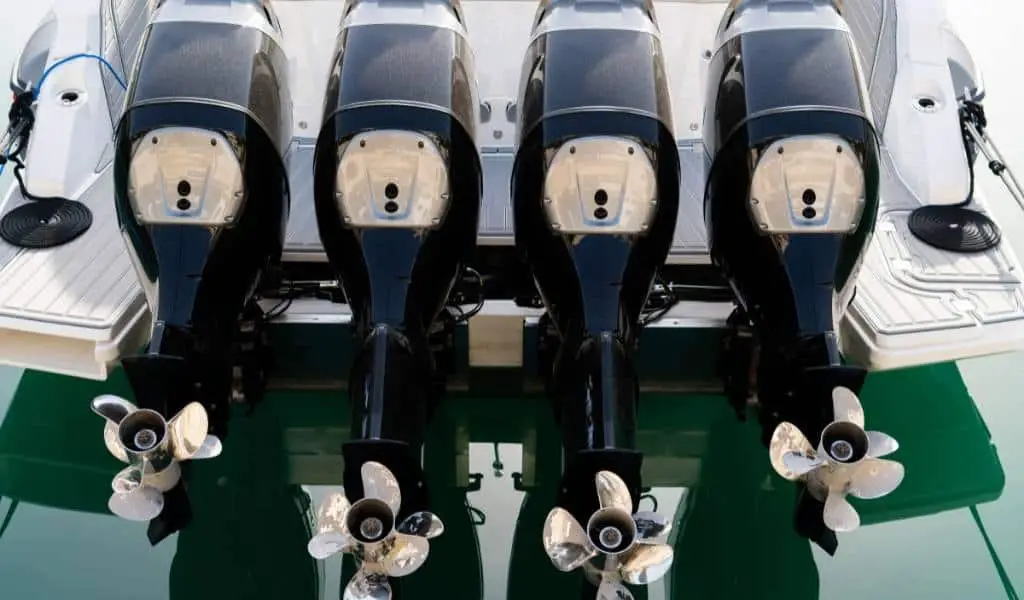

Half the performance problems I see come from running the wrong shaft length. The motor runs, sure, but it's either cavitating at the surface or dragging the lower unit too deep. Both kill your speed and burn fuel.

How to Measure Shaft Length Correctly

Shaft length is measured from the top of the clamp bracket—that's the highest point where the motor bolts to the transom—straight down to the cavitation plate. The cavitation plate is the flat horizontal plate right above the prop.

Grab a tape measure. Hook it on the top edge of the clamp bracket and pull it down to the top surface of the cavitation plate. That number is your shaft length.

- 15 inches = Short shaft

- 20 inches = Long shaft

- 25 inches = Extra-long shaft

Don't measure the entire leg from the cowling. That's not your shaft length—it includes the midsection and powerhead.

If you want to understand more about selecting the right shaft length and how it impacts motor performance, check out our detailed blog on long shaft vs. short shaft outboards: choosing the right length.

Measuring Your Transom Height

Now measure your boat. Find the lowest point on the inside of the transom where it meets the hull. Measure straight up to the top edge of the transom where the motor mounts.

Most small boats (dinghies, inflatables, small jons) have 15 to 17-inch transoms. Mid-sized fishing boats and RIBs run 19 to 21 inches. Sailboats and larger offshore hulls often need 22 inches or more.

The goal: mount the motor so the cavitation plate sits level with or slightly below the hull bottom. This keeps the prop submerged in clean water without excessive drag.

Jim Walker from JLM Marine, who's designed outboard cooling systems, puts it plainly: "Match your transom measurement to the motor's shaft length so the cavitation plate sits level with or just below the hull bottom. When it's right, the prop stays submerged and bites clean water. When it's wrong, you get ventilation, drag, or both."

| Shaft Type | Measurement | Typical Transom Height | Common Applications |

|---|---|---|---|

| Short | 15 inches | 15-17 inches | Inflatables, tenders, small dinghies, shallow-water skiffs |

| Long | 20 inches | 19-21 inches | RIBs, sailboats, small to mid-sized fishing boats |

| Extra-Long | 25 inches+ | 22+ inches | Offshore boats, larger sailboats, performance hulls |

Short Shaft Motors: Where They Work

Short shafts belong on boats with low transoms—your inflatables, car-toppers, and shallow-draft fishing rigs. The motor sits higher on the transom, so the prop runs closer to the surface.

Advantages:

- Lower draft lets you get into skinny water without beating up your skeg

- Easier to tilt and store on small transoms

- Lighter overall setup for tiny boats

Disadvantages:

- Prop ventilates in chop. You'll hear the RPMs spike and see zero speed increase—just noise and cavitation

- Water pump can suck air if the intake breaks the surface, leading to overheating

- Useless in rough water where the stern bounces

I see guys run short shafts on jon boats for river fishing and duck hunting. They need to clear stumps and sandbars, and they're not running in three-foot seas.

Long Shaft Motors: Where They Work

Long shafts are standard on anything with a higher transom or any boat that sees chop. The extra five inches keeps the prop deep in solid water, even when the bow lifts.

Advantages:

- Prop stays submerged in waves and wakes—consistent thrust, no ventilation

- Better top-end speed and hole shot because the prop doesn't lose bite

- Required for sailboats and taller-transom hulls

Disadvantages:

- More draft—you'll hit bottom sooner in shallow areas

- Heavier lower unit

- Unnecessary drag if your transom is too short

Sailboats almost universally need long or extra-long shafts because of their high transoms and deep keels. Try a short shaft on a sailboat and the prop will be half out of the water.

Performance Issues from Mismatched Shaft Length

Too Short:

You get cavitation. The prop chews air instead of water. Symptom: RPMs jump to redline but the boat barely moves. Water spits at idle but improves with throttle—classic sign the intake is borderline. If you're overheating at cruising speed, the pump might be sucking air intermittently.

Walker lists the symptoms: "Too short: RPM spikes without speed increase… Too long: Sluggish acceleration. Top speed lower than spec."

Too Long:

The gearcase drags in the water like an anchor. Symptom: Acceleration is slow, top speed falls short of the spec sheet, and you burn more fuel to go nowhere. In shallow water, you're constantly hitting the prop on the bottom.

We rebuilt a Verado lower unit for a guy in the Keys who swapped a 20-inch (short) shaft to 25-inch (long) because he moved the motor from a flats skiff to a bay boat with a deeper transom. The conversion involved pressing new bearings, replacing prop shaft seals, and shimming everything to spec. Saved him from buying a whole new motor.

If you plan to do such lower unit adjustments yourself, learning proper installation techniques including the use of jack plates is essential. Our blog on installing a jack plate and its benefits for shallow water boating covers this in-depth.

Common Motor Models and Shaft Codes

Manufacturers mark shaft length in the model number, usually with a letter code:

- S = Short (15")

- L = Long (20")

- XL or X = Extra-Long (25")

For example, a Honda BF15 comes in both S and L versions. Mercury Verados often have 20-inch (L) and 25-inch (XL) options for offshore rigs. Yamaha's F250 and F300 V6s come in 25-inch (L) and 30-inch (XF) lengths for big center consoles.

Always verify the code on the serial plate or by measuring yourself. Don't trust what the previous owner says.

For more assistance decoding serial numbers and model information, check out our comprehensive Yamaha outboard serial number guide.

Using Jack Plates and Brackets to Adjust

Sometimes you're stuck with a motor that's an inch or two off. A jack plate mounts between the transom and the motor, letting you raise or lower the mounting height and adjust setback.

Jack plates help if you're borderline—say, your transom is 18 inches and you have a 20-inch shaft. Raise the motor an inch, and the cavitation plate drops into the sweet spot.

Warning: Don't get creative. Raising the motor more than a couple inches changes the steering geometry and can introduce torque steer or prop blow-out. Setback affects weight distribution and handling. If you need more than minor adjustment, you probably have the wrong shaft length.

You can find jack plates and other accessories in our boat accessories collection to help optimize motor setup.

Repowering and Buying the Right Shaft Length

When you're buying a new motor or swapping to a different brand, the shaft length decision comes first—before horsepower, before features, before anything else.

Steps to Get It Right

1. Measure your current motor if you're replacing one. Pull the tape from clamp bracket to cavitation plate. If the old motor worked fine, that's your answer.

2. Measure your transom height. Even if you measured the old motor, double-check the transom. Some motors were mounted wrong from the factory, and you've been compensating without knowing it.

3. Check the boat specs. If you can find the original manufacturer specs for your hull, they'll list the recommended shaft length. That's gospel.

4. Consider your load and usage. If you're loading the boat heavy with gear and passengers, the stern will sit lower. You might need to go an inch longer to keep the prop submerged under load. Conversely, if you're running ultra-light for racing or shallow fishing, you might bias toward shorter.

5. Look for the shaft code in the model number. When shopping, confirm the listing shows "S," "L," or "XL" in the part number. If it just says "outboard motor" without specifying, ask. Don't assume.

6. Don't guess. If you're uncertain, call the dealer or send us the measurements. We'd rather spend five minutes confirming than deal with a return and a frustrated customer who lost a weekend of fishing.

OEM vs. Aftermarket Parts for Lower Unit Rebuilds

OEM parts are good quality, no question. But you're paying a huge premium for the logo on the box. A factory impeller kit might run $120 when an aftermarket equivalent costs $50.

Cheap aftermarket? Avoid it. The $15 kits from random online sellers use hard rubber that doesn't seal, housings that don't fit, and seals that leak within weeks. You'll tear the lower unit down twice, and you've wasted time and money.

Quality aftermarket is the move. Factories that produce OEM parts often have excess capacity and sell the same parts under different brands. JLM Marine sources directly from these manufacturers. You get factory-spec fit and materials without the dealership markup. The impeller seals properly, the shafts are dimensionally accurate, and the seals don't weep.

We've shipped kits to guys in Australia and Europe who had the exact same lower unit issues we see in Florida and California. The parts work because they're made to the same specs.

To browse trusted parts for brand-specific repairs, visit our Evinrude water pump impeller kit collection or explore other OEM and aftermarket options.

Repair Costs and When to Replace vs. Rebuild

Labor for a full lower unit rebuild runs $400 to $1,000 depending on your shop's rate—figure 4 to 10 hours at $75 to $150/hour. Add parts (seals, bearings, gears if damaged), and you're looking at $600 to $1,500 total for a rebuild.

Compare that to a full lower unit replacement: aftermarket units cost $1,000 to $3,000, OEM runs $2,000 to $9,000. Swapping a complete unit takes 1 to 2 hours.

When to rebuild: Minor seal leaks, bad impeller, or surface rust on gears. The shafts are straight, the bearings aren't howling, and the gears have no missing teeth.

When to replace: Cracked housing, bent shafts, stripped gears, or severe corrosion. If the estimate for rebuild parts exceeds half the cost of a replacement unit, just swap it.

Most US shops don't rebuild anymore—it's time-intensive and hard to warranty. If you're doing it yourself, it's worth rebuilding if you have the tools and patience.

One guy repaired a cracked Evinrude/Johnson lower unit with TIG welding after cleaning the casting and replacing all seals. Post-repair water test in sand and river conditions showed zero water intrusion. That's salvage at its best, but it requires welding skills most people don't have.

For detailed maintenance and rebuild tips to extend your motor life, see our guide on maintaining your outboard’s gearcase: Mercury vs. Yamaha.

Practical Maintenance to Prevent Lower Unit Failures

Keep the lower unit oil clean and full. Check it every season or every 50 hours, whichever comes first. Milky oil means water intrusion—don't wait for the gears to seize.

For all your parts and repair needs, visit our home page collections at JLM Marine to find premium marine engine parts direct from the factory, ensuring quality and prompt worldwide shipping.

Leave a comment

Please note, comments need to be approved before they are published.