Oil Injection vs. Pre-Mix: 2-Stroke Fueling Methods Compared

- Quick Takeaways

- How Oil Injection Works in Real Use

- Pre-Mix: Full Control, Full Responsibility

- Converting Injection to Pre-Mix

- Oil Types: Injector vs. Pre-Mix Formulations

- Oil Injection vs. Pre-Mix: Side-by-Side

- Decision Guide: Which System for Your Engine

- Troubleshooting Injection Problems

- Why Modern Oils Changed the Game

- Real-World Cost Breakdown

- Installation Tips for Pre-Mix Conversion

- The Ethanol Problem in Both Systems

- Common Myths About 2-Stroke Oiling

- What We Run at JLM Marine

- Final Daily Maintenance Tip

Quick Takeaways

- Oil injection meters oil automatically—lean at idle (120:1), rich at throttle (20:1)—cutting plug fouling but relying on pumps that can fail if you skip maintenance or use wrong oil

- Pre-mix gives you fixed ratios (32:1 to 50:1) you blend by hand—no pump failures, but you're over-oiling at idle and risking lean spots at wide-open throttle

- Modern synthetics and better ignitions make both work well now, unlike the old petroleum-based oils that smoked and fouled constantly

- Performance machines (Banshee, Honda 250R) shipped with pre-mix from the factory because racers wanted zero failure points

How Oil Injection Works in Real Use

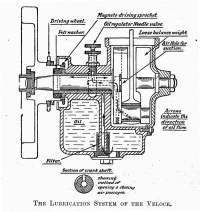

Your injection pump ties to the throttle cable or runs electronically off sensors. At idle, the system dribbles in just enough oil—often 120:1—to keep the crank bearings wet without drowning the combustion chamber. Pin it, and the ratio jumps to 20:1 or richer to protect the top end under load. This variable metering is why injected engines run cleaner at low RPM: less oil means less unburned residue coating your plug and puffing out the exhaust.

The pump itself is either mechanical—driven by a cable off the crankshaft or throttle linkage, common on older Yamaha Blasters and EZGO golf carts—or electronic, where an ECU reads throttle position and engine speed to pulse a solenoid valve. Electronic systems like Ski-Doo's Rotax E-TEC hit EPA emission targets years early because they meter oil so precisely, cutting smoke and plug deposits that plagued carbureted trail sleds.

Common Injection Failures and Symptoms

Injection pumps fail when the oil you're using is too thick (won't flow through the metering valve at idle) or too thin (doesn't build pressure in the pump chamber). Wrong oil viscosity has caused seizures in snowmobiles and PWC, especially when riders dumped cheap pre-mix oil into an injection tank designed for low-flash-point injector formulations.

Watch for these signs your pump is dying:

- Air bubbles in the oil line while the engine runs—means the pump diaphragm is cracked or the inlet check valve is stuck

- Excessive blue smoke at idle that clears under throttle—stuck-open metering valve is dumping oil

- Dry spark plug and a seized top end after a long pull—the pump quit feeding oil at high demand

On mechanical pumps, the plastic drive gear strips after 300 to 500 hours if the oil gets gummy. You'll hear a faint clicking from the pump body but see no oil moving in the sight glass. One Sea-Doo owner's check valve in the banjo fitting failed, starving the engine until it locked up, which is why some riders just disable the system and go pre-mix for peace of mind.

Hoses get brittle, especially if you're running ethanol gas. A pinhole leak sucks air instead of oil, and you won't know until the piston scores. Check every rubber line annually and replace any that feel stiff or show cracks under a flashlight. For original replacement parts and quality supplies for your watercraft, explore our extensive Boat Accessories collection.

Pre-Mix: Full Control, Full Responsibility

You're mixing a fixed ratio—typically 32:1 (4 oz oil per gallon) for hard riding or 40:1 to 50:1 for lighter use with premium synthetics. Pour the oil into your gas can first, add fuel, shake it hard to emulsify, then fill the tank. If the oil settles at the bottom, the first few minutes of running are lean and the rest is rich, which defeats the point.

Pre-mix always over-oils at idle because the ratio doesn't change. That's why you see more plug fouling and blue smoke when you're putting around the yard on a pre-mixed Blaster. At wide-open throttle, though, a 32:1 mix might still be leaner than the 20:1 an injection system would feed, so racers often go richer—25:1 or even 20:1—when ambient temps hit 90°F or they're running sustained high RPM.

Pre-Mix Ratios by Application

- Trail riding, moderate load: 40:1 with a JASO FD synthetic like Amsoil Dominator

- Racing, sustained WOT: 25:1 to 32:1; richer ratios sacrifice a bit of power (old Bridgestone tests showed slight drops going from 20:1 to 30:1) but add a safety margin against heat seizure

- Break-in on a fresh top end: 20:1 for the first tank, then step to your normal ratio

Modern synthetic oils burn so clean that a 50:1 mix today produces less smoke and deposits than a 20:1 petroleum blend from the '80s. But don't confuse "clean burn" with "enough protection"—if you're riding hard in the sand dunes, don't gamble on 50:1 just because the exhaust looks clear.

For rebuilding or maintaining your carburetor after switching to pre-mix, don't miss our detailed Carburetor Repair Kit collection, offering premium parts to keep fuel delivery precise.

Converting Injection to Pre-Mix

If you're yanking the oil injection, you'll need to block off the oil inlet on the crankcase and plug any vacuum lines that ran to the pump. On a Yamaha Blaster or similar ATV, the pump mounts to the engine and feeds through a banjo bolt on the intake manifold. Remove the pump, install an aluminum block-off plate with a fresh O-ring, and torque it to spec (usually 6–8 ft-lbs; check your service manual). Leave the pump cable attached but zip-tie it out of the way so it doesn't flop into the chain.

Some engines use a vacuum-operated oil valve—cap that vacuum line or the idle will surge. On EZGO golf carts, one owner disabled the crankshaft-driven pump and switched to 128:1 pre-mix (1 oz per gallon) with no need to seal the pump cavity extensively, but most mechanics recommend a tighter ratio like 85:1 (1.5 oz per gallon) to prevent lean seizures.

After the conversion, drain the old fuel, pull the carburetor, and clean the main jet. Injected engines often run a slightly leaner main jet because the oil arrives separately; with pre-mix, that oil is now in the fuel stream, effectively richening the mixture. You might need to drop one jet size to avoid loading up at mid-throttle. Explore our Carburetor collection for quality replacements and maintenance parts.

Oil Types: Injector vs. Pre-Mix Formulations

Injector-rated oils (often labeled "TC-W3" for outboards or "autolube" for Ski-Doo) have a lower flash point so they ignite instantly when misted into the intake tract. They're thinner at room temperature to flow through tiny metering orifices. Using pre-mix oil in an injection system can clog the valve or leave deposits in the pump chamber, and using injector oil in a pre-mix can lead to inconsistent suspension in the fuel if it doesn't emulsify well.

Pre-mix oils are formulated to stay blended with gasoline in the tank for days or weeks. They meet standards like JASO FC (low smoke, moderate protection) or JASO FD (lowest smoke, highest film strength). ISO-L-EGD is the European equivalent of JASO FD. Cheap oils skip these certifications and use heavier base stocks that don't burn completely, leaving brown varnish on the piston crown and exhaust port.

Stick with name-brand synthetics from Amsoil, Motul, Castrol, or similar. The difference between a $10 gallon jug and a $25 quart of JASO FD oil is the difference between pulling your top end apart every season and running 200 hours between rebuilds.

Oil Injection vs. Pre-Mix: Side-by-Side

| Aspect | Oil Injection | Pre-Mix |

|---|---|---|

| Convenience | Fill separate oil tank, forget about it; no measuring [^1] | Mix oil into every tank; messy, requires measuring cup and math [^1] |

| Ratio Flexibility | Variable: 120:1 idle, 20:1 WOT—optimized for load [^2] | Fixed: 32:1 to 50:1 all the time—compromise at every throttle position [^2] |

| Plug Fouling | Rare at idle due to lean mix; clean combustion [^1] | Common at idle; excess oil wets the plug and carbons the chamber [^1] |

| Failure Risk | Pump, hoses, check valves can fail; wrong oil kills it [^3] | Zero mechanical failures; only risk is mis-measuring the ratio [^1] |

| Maintenance | Inspect lines annually, change oil filter (if equipped), verify flow in sight glass | Just mix accurately; check spark plug color to confirm ratio |

| Smoke Emissions | Low at cruise with modern oils; injection meters less oil than pre-mix [^1] | Higher at idle; reduces under load but never zero with traditional ratios |

| Cost Per Hour | Injector oil is pricier per quart, but you use less overall [^1] | Pre-mix oil is cheaper in bulk, but you burn more total volume [^1] |

[^1]: Dirt Wheels Magazine: Oil Injection vs Premix

[^2]: PJ1: Is Oil Injection Better Than Premix?

[^3]: Sea-Doo Forum: Engine Failures, Oil Injected vs Premix

Decision Guide: Which System for Your Engine

Keep oil injection if:

- Your engine is a late-model outboard, snowmobile, or PWC with electronic metering—Rotax E-TEC systems have proven reliable over thousands of miles when maintained correctly

- You ride casually and value convenience over absolute control

- The pump and lines are in good shape (no cracks, no air in the sight glass, noHistory of wrong oil)

- You're willing to inspect hoses and the pump every 50 hours

Switch to pre-mix if:

- You're running a performance quad (Banshee, Honda 250R) or a vintage bike where the injection pump is 20+ years old and plastic gears are suspect

- You've had an injection failure before or the pump is making noise

- You race or ride wide-open for extended pulls and want the safety margin of a known-rich ratio

- You prefer mechanical simplicity and don't mind the extra step at the fuel station

For engines older than 2000: The rubber lines and plastic pump internals have aged. Unless you've already replaced every hose and rebuilt the pump, pre-mix is the safer bet. A $40 block-off kit and a ratio cup beat a $600 top-end rebuild.

Troubleshooting Injection Problems

If your injected engine is smoking more than it used to or the idle is rough:

- Check the oil level in the reservoir. Low oil can cause the pump to suck air, which looks like bubbles in the sight glass. Top it off with the correct injector-grade oil.

- Inspect the delivery line from tank to pump. Squeeze it—if it's stiff or cracked, replace it. Use OEM spec hose or a quality aftermarket line rated for oil; fuel line is too soft and will collapse under vacuum.

- Verify the pump is getting a signal. On cable-driven pumps, disconnect the cable at the carb end and confirm it pulls smoothly with throttle movement. On electronic pumps, a scan tool or multimeter can check the pulse signal from the ECU.

- Pull the spark plug. A wet, oily plug means the pump is over-delivering (stuck metering valve or wrong oil viscosity). A bone-dry, white plug means it's not delivering at all.

Why Modern Oils Changed the Game

Older petroleum 2-stroke oils had flash points around 400°F and left thick ash deposits. They didn't fully combust at low throttle, so injected engines still smoked and fouled plugs even with lean ratios. Synthetic esters and PAO-based oils burn at lower temps and leave almost no residue, which is why a modern Rotax or Mercury outboard can run 100:1 at idle without seizing.

Aviation mechanic Greg Perkins explained that with pre-mix, the fixed ratio forces too much oil past the piston and into the combustion chamber, fouling plugs, while oil injection targets the crank bearings directly and sends less oil upward. That's the chemical reason injection systems foul less: they're not drowning the plug in unburned oil during warm-up.

But here's the catch: synthetics also tolerate leaner ratios, so if your injection pump hiccups and drops to 150:1 for a few seconds, a good synthetic can still protect the bearings long enough for you to notice and shut down. Cheap petroleum oil would score the piston in that same window.

Real-World Cost Breakdown

Let's say you ride 100 hours a season on a Yamaha Blaster (6.5 gallons fuel capacity, avg. 25 mpg):

- Total fuel burned: 100 hours × 25 mph avg. speed ÷ 25 mpg ≈ 100 gallons

- Pre-mix at 40:1: 100 gal × 3.2 oz oil/gal = 320 oz = 2.5 gallons oil. At $25/gallon for JASO FD synthetic, that's $62.50/season.

- Oil injection: The pump might use 1.5 gallons over the same period (less oil overall due to lean idle metering). Injector oil costs $30/gallon, so $45/season.

Injection saves you $17.50 in oil but adds the risk of a $150 pump rebuild if it fails. Pre-mix costs more in oil but zero in pump parts. The math is tight, which is why the decision comes down to your risk tolerance and how much you value convenience.

Installation Tips for Pre-Mix Conversion

Tools you'll need:

- 8mm and 10mm sockets (pump mounting bolts on most ATVs)

- Ratio Rite measuring cup or equivalent graduated pitcher

- Block-off plate kit (aluminum preferred over plastic; check fitment for your model)

- High-temp thread sealant (Loctite 567 or similar) for any plugged vacuum ports

- New O-rings for the oil inlet banjo bolt

Steps:

- Drain the injection oil tank and remove it (or leave it in place and cap the outlet if you want to keep the stock look).

- Unbolt the pump from the engine case. On a Blaster, it's two 10mm bolts on the right side near the clutch cover.

- Install the block-off plate over the oil inlet port. Torque to 6-8 ft-lbs; over-torquing cracks the aluminum.

- Disconnect the oil delivery line at the intake manifold and plug the barb with a vacuum cap.

- If there's a vacuum line running to an oil valve, cap it at the carb or manifold end.

- Clean the carburetor main jet and pilot jet. Consider dropping the main jet one size (e.g., from 240 to 230) to compensate for the oil now in the fuel.

First ride, run a rich 25:1 mix and monitor the plug. If it's wet and black after a 10-minute ride, you're too rich—step to 32:1. If it's bone white, you're dangerously lean—go back to 25:1 or check for air leaks.

The Ethanol Problem in Both Systems

Ethanol attracts water, which phase-separates in the tank after a few weeks and sinks to the bottom. In a pre-mix setup, that water layer doesn't have any oil in it, so when the engine sucks it up, you're running straight gas for a few seconds—enough to score a piston if you're under load.

In an injection system, ethanol degrades the rubber pump diaphragm and the hoses faster than pure gas. We've seen hoses crack and leak after one season on E10 pump gas. Use ethanol-free gas (91 octane non-oxy is common at marine stations in the US) for both systems, or add a fuel stabilizer like Star Tron if you have to run E10. To find reliable fuel filtration options to protect your engine, visit our Fuel Filter collection.

Common Myths About 2-Stroke Oiling

Myth: "Oil injection is always less reliable than pre-mix."

Early systems from the '70s and '80s failed because riders used the wrong oil or never serviced the pump. Modern electronic injection on Ski-Doo sleds and Mercury outboards runs reliably for 500+ hours if you follow the maintenance schedule.

Myth: "Pre-mix gives you more power."

Not true with modern oils. Old tests showed a slight power gain at very lean ratios (30:1 vs. 20:1) because less oil means more fuel in the cylinder, but the difference is 1-2% and the seizure risk isn't worth it. Racers used pre-mix for control, not peak horsepower.

Myth: "You can use any 2-stroke oil in an injection system."

Wrong. Injector oils have specific viscosity and flash-point specs. Using a thick pre-mix oil will clog the metering valve and starve your engine. Always match the oil to the system.

What We Run at JLM Marine

We stock the correct injector-rated oils for most outboards—Mercury Premium Plus, Yamaha Yamalube 2M, and equivalent synthetics. You're not paying dealership markup when you order direct from us, and the oil meets the same TC-W3 specs the factory requires. For customers converting to pre-mix or running older outboards, we carry JASO FD synthetics in bulk so you're not stuck buying quart bottles at $15 each.

If you're tearing down a lower unit or doing a top-end rebuild and need to decide whether to keep the injection or go pre-mix, email us your engine model and usage pattern. We'll tell you which pump parts are available and whether it's worth the rebuild cost versus a simple block-off and pre-mix kit.

Explore our full range of Inboard & Outboard Motor Parts for all your maintenance and repair needs.

Final Daily Maintenance Tip

Every third fill-up, pull your spark plug and check the color. Milk-chocolate brown is perfect—means your oil ratio and jetting are spot-on. Black and wet means too much oil (lean out your pre-mix ratio or check for a stuck injection valve). White and dry means not enough oil—richen the mix immediately or verify your injection pump is flowing. This 30-second check will catch a failing pump or a bad mix before it seizes your top end.

For more expert advice on marine parts and maintenance, visit the JLM Marine home page.

Leave a comment

Please note, comments need to be approved before they are published.