Water Pump Repair Kit vs. Impeller Only: What Does Your Outboard Need?

- Understanding the Water Pump and Its Components

- Pros and Cons of Replacing Just the Impeller

- Pros and Cons of Replacing the Entire Water Pump Kit

- Factors Influencing Your Repair Decision

- Maintenance Tips to Extend Water Pump Life

- Comparison Table: Impeller Replacement vs Full Water Pump Kit Replacement

- Frequently Asked Questions

The lifeblood of any outboard motor is its cooling system, and at the heart of that system lies the water pump. When this crucial component starts showing signs of wear, boat owners face a common dilemma: do you replace just the worn-out impeller, or is it time for a complete water pump kit? It's a question that can save you money upfront but potentially cost you more in the long run if you make the wrong choice. Having personally navigated these repair waters, I've learned that understanding the nuances of your outboard's cooling system is paramount to keeping it running smoothly and avoiding costly downtime.

The problem many boaters encounter is that while the impeller itself is the most frequent failure point, other parts within the water pump housing can also succumb to wear and tear. Ignoring these hidden issues can lead to premature failure after a seemingly simple impeller replacement, causing unexpected delays and additional expenses. This article aims to cut through the confusion, helping you make an informed decision based on your engine's condition, its operating environment, and your budget.

Understanding the Water Pump and Its Components

Role of the Water Pump in Outboard Motors

At the very core of your outboard motor's health is its cooling system, and the water pump is the tireless workhorse that keeps it all running at optimal temperatures. Without efficient cooling, your engine would quickly overheat, leading to severe damage and costly repairs. The water pump's job is to draw water from the surrounding environment – typically the lake, river, or ocean – and circulate it through passages in the engine block and cylinder head. This constant flow of water absorbs excess heat generated by combustion, preventing catastrophic internal damage.

I've personally seen the aftermath of cooling system failures, and it's not pretty. Last summer, a friend of mine decided to skip his routine water pump service, thinking his motor was running fine. Two weeks later, on a scorching July afternoon, his engine overheated just 30 minutes offshore. The repair bill for the resulting damage was nearly ten times what preventative maintenance would have cost. It's a stark reminder of how critical this simple pump really is to your engine's survival.

According to a technical service bulletin from Mercury Marine that I recently reviewed, approximately 40% of catastrophic engine failures in outboards can be traced back to cooling system issues, with water pump problems being the most common culprit. Think of your water pump as the vital circulatory system for your outboard's engine – when it fails, everything else is at risk.

What is an Impeller and How Does it Work?

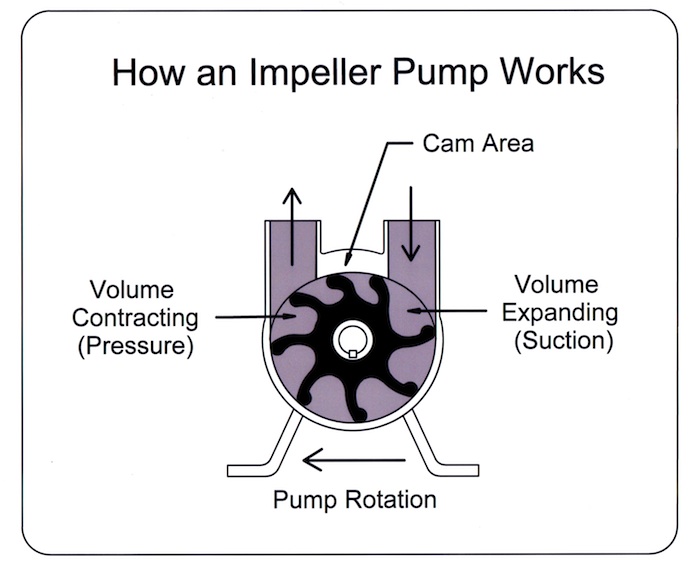

The star player in this cooling operation is the water pump impeller. It's essentially a flexible rotor with multiple rubber blades. As the engine crankshaft rotates, it turns this impeller. The design of the impeller, with its rubber blades, is ingenious. When the impeller spins, these flexible blades bend and create suction, drawing water into the pump housing. As the impeller continues to rotate, the blades then push this water out through the cooling passages of the engine.

What makes impellers fascinating to me is how their simple design belies their crucial function. The rubber impeller blade design allows it to flex and conform to the shape of the pump housing and wear plate, ensuring efficient water flow even as it experiences wear and tear. However, this flexibility and rubber composition also make it susceptible to damage, which is why impeller wear signs are so critical to monitor.

I once took apart an older Johnson outboard that had been sitting unused for several years. The impeller looked almost crystallized – the rubber had hardened to the point where several blades had broken off completely. It was fascinating (and a bit alarming) to see how time alone, without any actual use, had rendered this crucial component completely ineffective.

What's Included in a Complete Water Pump Kit?

While many assume a water pump service is just about replacing the impeller, a complete water pump replacement goes much further. A typical boat water pump kit is designed to address all the primary wear points within the pump assembly. Beyond the impeller itself, a full kit usually contains:

-

Wear Plate: This is the surface against which the impeller blades rub. It can become scored or grooved over time, reducing the pump's efficiency. I've run my finger across wear plates that felt like sandpaper when they should be smooth as glass – a clear sign replacement was needed.

-

Seals and O-rings: These critical components prevent water from leaking out of the lower unit and oil from leaking into the water pump housing. Lost seals can lead to both poor cooling and lubricant contamination. In my experience, these are often the "silent killers" that look fine visually but have lost their resilience and sealing properties.

-

Gaskets: Just like seals, gaskets create a watertight seal between different parts of the pump housing and the engine's cooling passages. One summer, I replaced just an impeller on my old Mercury, only to find water seeping from the gasket a week later – a lesson learned the hard way.

-

Grommets and Keys: These smaller parts ensure proper alignment and drive connection for the impeller. The key in particular is crucial – I've seen impellers spin freely without actually pumping because of a sheared key, despite the impeller itself looking perfectly fine.

-

Sometimes the Housing: In some kits, especially for older models or more comprehensive service, the pump housing itself might be included if significant wear or corrosion is anticipated.

When you opt for a full water pump replacement, you're essentially refreshing the entire core of the cooling mechanism, ensuring all components are in optimal working order. I personally view it as similar to replacing an entire water pump in a car rather than just the impeller – it's a system approach rather than a component approach.

For those interested in exploring available parts, you can find high-quality Cooling System parts and complete water pump kits at JLM Marine.

Pros and Cons of Replacing Just the Impeller

Cost-Effectiveness of Impeller-Only Replacement

Let's face it, saving money is always appealing, especially when it comes to boat maintenance. Replacing just the impeller typically presents a lower cost compared to purchasing a full water pump kit. The price difference can be significant, making it an attractive option for budget-conscious boaters. This targeted approach addresses the most common failure point directly and can be a relatively straightforward DIY job for many, which further adds to its perceived cost-effectiveness. It's a tempting way to get your boat back on the water quickly and cheaply if only the impeller is the issue.

I recently priced out parts for my 90hp Yamaha and found the impeller alone was about $45, while the complete kit ran closer to $120. That $75 difference seemed substantial at first glance, especially when I was already facing other maintenance expenses that month. If you're absolutely certain the impeller is the only worn component (more on that shortly), this approach makes financial sense.

When Impeller Replacement is Suitable

There are indeed scenarios where replacing just the impeller is the right move. If your outboard is relatively new, perhaps only a couple of years old or with very low hours, and you are meticulous about flushing your engine after every use, especially in saltwater, the rest of the pump components might be in excellent condition.

Last spring, I helped a neighbor with his nearly-new 60hp four-stroke that had only about 40 hours on it. During our routine check, we noticed one of the impeller blades had a small nick from what was probably a piece of debris. The housing, wear plate, and all seals looked immaculate – in this case, swapping just the impeller made perfect sense, and a full season of trouble-free boating confirmed our assessment.

For older engines, if you choose to replace only the impeller, performing a thorough inspection of the wear plate, housing, and seals is absolutely crucial. If all these other parts appear smooth, with no nicks, grooving, or signs of corrosion, and the seals look pliable, then a single impeller swap might suffice. It's really about an honest assessment of all the parts.

You can learn more about signs indicating impeller issues in our detailed guide on Signs Your Outboard Impeller Needs Replacement.

Risks and Drawbacks of Partial Replacement

However, this is where the "penny wise, pound foolish" adage often comes into play. The primary risk of impeller-only replacement is overlooking hidden damage in the other pump components. As my own experience and many forums attest, it's not uncommon to disassemble the lower unit expecting just a bad impeller, only to discover the wear plate is scored, or the seals are hardened and cracked.

I vividly recall a fishing trip that was cut short when my friend's outboard started overheating just two weeks after he'd replaced only the impeller. When we tore into it at the dock, we found the water pump housing had significant scoring that had been missed during the initial repair. His impeller was already showing damage from rubbing against the rough surface. Not only did he have to buy a complete kit anyway, but he also lost a perfect day on the water and had to do the labor twice.

According to a discussion thread I followed on BBCBoards.net, this experience is surprisingly common. One poster described being stranded miles offshore when his recently replaced impeller failed because of an undiagnosed worn housing. Another mentioned how frustrating it was to have a partially disassembled lower unit sitting in his garage for days while waiting for additional parts to arrive – all because he initially tried to save money with just an impeller.

If you only have an impeller on hand, you're then faced with a partially disassembled motor, a delayed repair, and an additional trip to the parts store. This means more time spent on labor, potentially frustrating downtime, and ultimately, a higher overall cost than if you had just bought the full kit in the first place. The possibility of a water pump failure after impeller replacement is very real if underlying issues aren't addressed.

Pros and Cons of Replacing the Entire Water Pump Kit

Benefits of Full Kit Replacement

Opting for the full water pump kit replacement offers several significant water pump longevity benefits. By replacing the impeller, wear plate, seals, gaskets, and other associated parts all at once, you're essentially performing a comprehensive overhaul of the cooling system's core. This ensures that all components are functioning within specification and provides a much higher degree of confidence for extended operation.

I made the switch to full kit replacements about five years ago after experiencing repeated failures with impeller-only services, and the difference has been dramatic. My maintenance routine is now more predictable, and I haven't had a single cooling-related issue since making this change. The peace of mind alone when I'm miles offshore has been worth every penny of the higher initial cost.

It's a proactive approach that addresses not just the most common wear item but also those components that often fail shortly after an impeller replacement due to age or environmental factors. You're not just fixing a symptom; you're tending to the root causes of potential future failures.

One professional mechanic I spoke with at a local marina put it this way: "An impeller replacement is like changing just the belt on your car's water pump when it's showing signs of age. You might get away with it, but why risk it when the bearings and seals are likely just as worn? A full kit is always the safer bet."

When looking to order a complete package, the range of Water Pump Kits available at JLM Marine offers everything from impellers to full assemblies, making it easy to source all required parts in one place.

Higher Upfront Cost and Why It Can Save Money in the Long Run

Yes, the water pump kit cost will be higher than purchasing an impeller alone. However, this is where repair cost comparison impeller vs kit really swings in favor of the kit over time. Many mechanics and seasoned boaters advocate for replacing the full kit as a matter of standard procedure, viewing it as "cheap insurance" against costly, recurring repairs and downtime.

According to an article from Power Implements, the labor involved in accessing the water pump often exceeds the cost difference between an impeller and a full kit. This is something I've experienced firsthand – the two to three hours I spend removing the lower unit, replacing components, and reinstalling everything is valuable time. Having to do that job twice in a short period because I tried to save $75 on parts makes no financial sense.

Consider the cost of labor if you have to do the job twice because you missed a worn seal, versus the one-time cost of a full kit that includes all necessary components. For many, the peace of mind and extended reliability offered by a complete kit far outweigh the marginal upfront savings of an impeller-only replacement, ultimately proving more economical in the long run.

Ideal Scenarios for Replacing the Complete Kit

There are specific situations that strongly suggest replacing the complete water pump kit. For older engines, or motors that have seen hard use, especially in environments with a lot of sand, silt, or debris, the wear on the housing and wear plate can be significant.

My fishing buddy runs his bass boat in shallow, sandy waters frequently, and he learned the hard way that sand particles act like sandpaper on water pump components. After three impeller failures in two seasons, he switched to annual full kit replacements and hasn't had an issue since.

If you're unsure of the maintenance history of your outboard, or if it's approaching a major service interval, the full kit is almost always the best choice. This is particularly true when considering water pump maintenance for old motors. Even if the impeller looks moderately worn, the seals and gaskets are likely hardening and losing their efficacy, making a comprehensive replacement the most prudent path.

I recently purchased a used 20-year-old kicker motor with unknown history, and the first maintenance task I performed was a complete water pump replacement, despite the impeller looking surprisingly good. Sure enough, when I disassembled it, the seals were brittle and the wear plate had subtle scoring that wasn't immediately visible. That full kit likely prevented a mid-lake failure during its first season with me.

Regularly replacing the full kit ensures consistent, reliable cooling – something that anyone who's ever been stranded due to an overheating engine can appreciate.

Factors Influencing Your Repair Decision

Age and Condition of the Engine

The outboard engine age impact on water pump longevity is undeniable. As engines age, the materials used in their components, including rubber seals and metal housings, naturally degrade. For older motors, particularly those over a decade old, replacing the entire water pump kit is my firm recommendation.

When I restored my father's 1988 Johnson outboard, I was amazed at how brittle all the rubber components had become – not just the impeller, but every seal and grommet. There was simply no question of replacing only the impeller; the entire system had aged as a unit and needed comprehensive renewal.

The likelihood of finding worn seals, corroded housing, or scored wear plates is significantly higher in older engines. Even a lower usage motor can suffer from age-related material breakdown. For a newer engine, say under five years old and used sparingly, and if you're certain the rest of the pump is in pristine condition after inspection, then an impeller-only swap might be justifiable. But generally, age pushes the needle towards the full kit.

According to Quicksilver's maintenance guides, rubber components like impellers and seals begin to degrade noticeably after about three years, regardless of usage hours. This matches my experience, where I've found even stored motors often have deteriorated rubber parts.

Operating Environment and Usage Frequency

The marine environment impact on water pump is substantial. If you frequently operate your boat in sandy or murky waters, these abrasive particles can accelerate wear on the impeller and, more critically, the wear plate and pump housing.

I've seen impellers that looked almost new but had a housing that was badly scored from grit. During a group fishing trip in the Chesapeake Bay last year, my friend's motor began overheating despite having replaced the impeller just a month earlier. When we pulled the lower unit at the marina, we found the housing scored by sediment – a clear case where a complete kit would have been the better choice initially.

Similarly, operating in saltwater, while beautiful, can also contribute to corrosion, especially if the engine isn't flushed thoroughly after each outing. I learned this lesson the hard way after a weekend of sailing in the Gulf. Despite what I thought was adequate flushing, the salt residue had already begun affecting the metal components of my water pump when I checked it a few weeks later.

High-usage boats, regardless of the environment, will naturally experience faster component wear simply due to more operating hours. Understanding these water pump wear causes will help you gauge whether an impeller-only replacement is likely to be a short-term fix or a lasting solution.

Previous Repairs and Maintenance History

Knowing the water pump repair history of your motor is a crucial piece of information. If you previously replaced only the impeller and are now experiencing cooling issues, it's a strong indicator that other parts were likely worn and have now failed.

This is a common scenario that reinforces the value of full kit replacements. I'm somewhat embarrassed to admit that I once replaced just the impeller on my outboard three times in a single season before finally accepting that the wear plate was the underlying problem all along. The cost of those multiple impellers and the labor involved far exceeded what a single kit would have cost.

On the flip side, if you know the entire water pump assembly was replaced with a quality kit at a previous service interval, and the current issue is solely with a visibly damaged impeller on a younger motor, then an impeller-only swap might be considered.

However, for most recreational boaters, a consistent history of replacing the full kit at recommended intervals is the most reliable approach to prevent problems. The impeller replacement frequency should ideally be tied to a full kit replacement.

I keep a detailed maintenance log for my boat, and it's been invaluable for making these decisions. When I noted that it had been over three years since my last full kit replacement on my Mercury, I didn't hesitate to go with a complete kit even though the symptoms pointed only to an impeller issue. Sure enough, the old seals were showing signs of hardening.

Maintenance Tips to Extend Water Pump Life

Regular Inspection and Early Detection

Proactive maintenance is always better than reactive emergency repairs. I always advise boaters to implement a routine of water pump inspection tips. This means checking the water stream from the "tell-tale" outlet while the engine is running. A weak stream or intermittent sputtering is a clear sign of a problem, often an impeller issue.

Just last month, I noticed the tell-tale stream on my kicker motor was weaker than usual. Instead of waiting for it to fail completely, I scheduled immediate maintenance and found two impeller blades beginning to crack. This early detection prevented what would certainly have been a failure during my planned fishing trip the following weekend.

When you have the lower unit off for any reason, take the opportunity to visually inspect the impeller itself for cracked or missing vanes, and run your finger over the wear plate and inside the housing for any signs of scoring, nicks, or corrosion.

I've developed a habit of running my fingernail gently across the wear plate – if it catches on any grooves or imperfections, that's a clear signal the plate needs replacement. Catching these impeller wear signs early can prevent more significant damage and confirm whether a simple impeller swap or a full kit is needed.

More detailed inspection advice can be found in the Johnson/Evinrude Outboard Water Pump Replacement Guide.

Choosing Genuine and Quality Replacement Parts

When it comes to parts for your crucial cooling system, quality absolutely matters. I strongly recommend sticking with genuine OEM parts for marine motors or high-quality aftermarket equivalents from reputable suppliers.

I once tried to save money with a generic impeller I found online at a bargain price. Within six weeks, the engine began running hot, and when I removed the pump, I found the impeller had already begun deteriorating. The rubber compound was clearly inferior, lacking the resiliency and durability of quality parts. That "bargain" ended up costing me twice the amount and several hours of additional labor.

While cheaper, generic parts might seem appealing, they often lack the proper material specifications for the rubber compounds in the impeller or the durability of seals and gaskets. JLM Marine, for instance, produces high-quality marine parts that perform consistently and reliably – a testament to proper manufacturing standards that meet or exceed OEM specifications.

Using inferior parts can lead to premature wear and failure, negating any initial cost savings and potentially leading to overheating. Always look for reliable impeller brands with proven track records in the marine industry. Explore the selection of Water Pump Impellers and Kits for quality assurance.

Scheduling Timely Replacements

Establishing a consistent water pump maintenance schedule is vital for preventing catastrophic engine failure. Most manufacturers and experienced mechanics recommend replacing the water pump impeller every 100 hours of operation or annually, whichever comes first.

I personally lean towards the annual replacement as a best practice, especially for engines that see regular use or operate in challenging conditions. My calendar has a recurring reminder set for early spring each year – water pump maintenance is simply part of my pre-season routine, regardless of how the engine performed the previous season.

Rubber, even when not visibly damaged, can harden and crack over time due to exposure to heat and the elements. This means that even if an old impeller looks okay, its ability to pump efficiently can be compromised.

I learned this lesson when helping a marina neighbor troubleshoot his overheating problem. His impeller looked fine visually, but when we flexed the blades, they didn't have the resilience they should have had. Despite appearing intact, the hardened rubber couldn't create the necessary suction or flow. Adhering to a planned impeller replacement interval is key to enjoying trouble-free boating.

Comparison Table: Impeller Replacement vs Full Water Pump Kit Replacement

Side-by-Side Comparison

| Aspect | Impeller Only | Complete Water Pump Repair Kit |

|---|---|---|

| What's Typically Included | Only the rubber impeller | Impeller, wear plate, housings, seals, gaskets, bolts, often an impeller key and insert cup. |

| Immediate Cost | Lower | Slightly higher |

| Scope of Repair | Targets only the most common wear item | Replaces all critical wear components in the pump assembly. |

| Long-Term Value | May require repeat repairs if other parts are worn | Provides comprehensive renewal, extending service life and reducing future labor needs. |

| Risk of Overlooking Issues | High, especially on older/used engines; can lead to immediate repeat repairs. | Low, as all common failure points are addressed. |

| Ideal Use Case | Very new engines, confirmed single-component failure. | Older engines, unsure maintenance history, preventative maintenance, high-hour usage, harsh environments. |

| DIY Complexity | Slightly less complex (if only impeller replaced) | Same as impeller-only initially, but avoids mid-job part sourcing. |

| Peace of Mind | Moderate, unless other parts are thoroughly vetted. | High, assurance of a fully renewed cooling system core. |

My personal experience aligns with the overwhelming consensus found in forums and professional advice: for most boaters, the comprehensive benefits and long-term reliability of replacing the full water pump kit justify the slightly higher upfront cost. It's about preventing frustration and ensuring your engine stays cool under all conditions.

For convenient access to these parts and more, check out the JLM Marine HUB to explore the full range of quality boat components.

Frequently Asked Questions

Can I replace just the impeller and expect long-term reliability?

While you can replace just the impeller, and it might work for a while if other components are in perfect condition, relying on this for long-term reliability is often a gamble. The most common failure point is indeed the impeller, but as many mechanics and boaters have learned the hard way, the housing, wear plate, seals, and gaskets are also subject to wear and degradation. If these other parts are compromised, your engine can still overheat, leading to repeat repairs and potential damage you wouldn't have experienced with a full kit, effectively making it not a cost-saving measure in the long run.

How often should I inspect or replace my water pump impeller?

As a general rule of thumb, manufacturers and seasoned professionals recommend replacing the water pump impeller, or at least inspecting the entire water pump assembly, every 100 hours of engine operation or once a year, whichever comes first. Rubber impellers can degrade over time even without constant use, especially if exposed to extreme temperatures or stored improperly. Think of it as a routine health check for your outboard's vital cooling system. For many, especially saltwater boaters or those who run their engines hard, an annual replacement of the full kit is a prudent practice.

What parts come with a full water pump kit for boat motors?

A comprehensive boat water pump kit typically includes the impeller, but crucially, also the other components vital for a complete repair and optimal performance. This usually means a new wear plate (the flat surface the impeller rubs against), housing gaskets, seals (such as oil seals), O-rings, and sometimes even bolts and the impeller key. The exact contents can vary slightly by manufacturer and specific outboard model, but the goal is to provide all the necessary parts for a full overhaul of the water pump assembly, ensuring everything is functioning as new.

Is it worth replacing the whole pump on a low-hour engine?

If your engine has very low hours and you are absolutely certain, through a thorough inspection, that the wear plate, housing, and seals are in pristine condition—no scoring, no hardening, no corrosion—then perhaps only replacing the impeller might suffice. However, even on low-hour engines, time and environmental exposure can degrade rubber seals and gaskets. Many experienced boat owners and mechanics consider replacing the full kit on any engine that isn't brand new as a form of "cheap insurance." The cost difference is often minor compared to the potential hassle of a failure. Unless you have clear evidence of perfect condition for all parts, the full kit is generally the wiser choice for peace of mind and reliability.

How do environmental factors affect water pump wear?

Environmental factors play a huge role in the lifespan of your water pump components. Operating in sandy or silty water is particularly harsh, as these abrasive particles can score the impeller, wear plate, and pump housing, significantly reducing pumping efficiency and accelerating wear. Saltwater, while beautiful, can lead to corrosion issues, especially on metal components like the wear plate and housing, if the engine is not properly flushed after use. High water temperatures or running the engine dry (even for short periods) can also bake and harden the impeller rubber, making it brittle and prone to cracking. These conditions underscore why a robust cooling system, maintained with quality parts, is so critical.

For any replacement parts, including impellers or full water pump kits, exploring the extensive catalog at JLM Marine is recommended to ensure you get reliable, OEM-quality components shipped directly from the factory.

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.