Used Outboard vs. New Outboard: Making the Right Choice

- Why Part Quality Actually Matters

- New Parts: What You're Paying For

- Used Parts: When They Work

- The Real Risks With Used

- Parts You Should Never Buy Used

- Parts That Are Fine Used

- Which Route Fits Your Situation

- Where to Buy Matters

- OEM vs Aftermarket Quality

- How to Inspect Used Parts Before Buying

- Maintenance After Installing Used Parts

- Common Questions

- Practical Tip

After two decades wrenching on outboards, I've replaced thousands of parts and seen boats return again and again because the owner made the wrong call on used versus new. The decision's straightforward if you know what to look for, but get it wrong, and you'll be dropping the lower unit twice on the same weekend.

The key question isn’t "which costs less?" It’s "which part, on which engine, for what kind of use?" A used cowling is usually fine. A used ECU is a gamble. Let’s break it down.

Why Part Quality Actually Matters

Quality parts stop comebacks. A $40 water pump impeller that cracks after 50 hours means dropping the lower unit again, bleeding a weekend, and maybe scoring the pump housing if it goes south. I've seen failed lower unit seals flood powerheads because someone used a $6 eBay seal kit instead of spending $25 on the right one.

Good parts install right the first time. Cheap aftermarket shifter shafts with sloppy tolerances cause missed shifts. OEM or quality aftermarket bearings seat smoothly without force. When parts are machined to spec, installation time cuts in half, and your engine runs like it should.

You’re usually replacing parts in three scenarios: scheduled service (impellers, anodes, lower unit oil seals), preventative upgrades (better thermostats, stainless fasteners in saltwater), or failures (broken shift shafts, seized water pumps, blown powerheads). Each has different stakes.

New Parts: What You're Paying For

OEM parts match exact factory specs. A Mercury lower unit seal kit for a 90HP fits without modification—no trimming, filing, or praying. Yamaha impellers use the proper rubber hardness (durometer) that won’t turn to stone after a season. These parts are engineered by the same factory that built your engine.

Warranty coverage usually runs 1-3 years, sometimes longer on powerheads. If a new fuel pump diaphragm fails after six months, you’re covered. This safety net matters on a $400 VST assembly.

Material improvements show in new parts. Modern stainless prop shafts resist corrosion better than old 1998 alloys. Newer composite impellers tolerate higher temps. New 4-stroke powerheads assembled in 2024 use better piston ring metallurgy than 2010 models, often improving fuel economy 20-30% in higher horsepower ranges.

The biggest win: zero history. You get no saltwater corrosion, no missed oil changes, no sand sucked through the water intake. The part starts fresh with you.

Used Parts: When They Work

Cost savings attract most buyers. A used lower unit for a 115HP Yamaha may cost $600 versus $2,200 new. A used trim/tilt assembly could be $300 instead of $950. That’s 60-70% cheaper.

Discontinued parts make used the only option. Running a 1996 Johnson 150HP? New powerhead parts are impossible to find. I helped a commercial crew in Australia source a used stator for a discontinued Evinrude—kept their boat running three more seasons.

Non-critical external parts are safe picks. Cowlings, mounting brackets, external fuel tanks, trim tabs—they don’t have hidden wear. A cowling either has cracks or doesn’t. A stainless swim bracket either fits or doesn’t.

Used parts keep serviceable material out of landfills, good for anyone who cares. A decent used part beats a new one rusting in a dump six months later.

The Real Risks With Used

Unknown wear bites you hard. A used water pump housing may look good but hide deep scratches that shred a new impeller in 20 hours instead of 200. A used powerhead might have 1,200 or 3,000 hours—you probably won’t know without logs.

No warranty means you shoulder the failure. If a used fuel injector clogs after a week, it’s your fix and your money. If it fries the VST, you’re on the hook.

Invisible issues haunt electronics and internals. A used ECU may have corroded circuit board traces that fail intermittently. A used lower unit might have a bent shift shaft that won’t engage until installed. A used starter could have brushes left for a handful of starts.

Some sellers mislead. "Low hours" outboards with repainted powerheads hide corrosion. "Freshwater only" lower units sometimes have barnacle scars inside water passages.

Parts You Should Never Buy Used

- Fuel system electronics: VST assemblies, ECUs, injectors. These fail invisibly and can cause catastrophic engine damage. A $600 used VST that takes out a $4,000 powerhead isn't a bargain.

- Internal engine seals and gaskets: If you’re opening the powerhead, always install new piston rings and head gaskets. Used seals invite return visits.

- Safety-critical parts: Steering cables, kill switches, fuel hoses. They wear and fatigue—don’t risk it.

- Bearings and bushings: Used lower units might look good but wear prop shaft bearings that cause vibration and shaft failure. Bearings cost $60 new; shafts $400.

Parts That Are Fine Used

- Cowlings and externals: Easy to check for cracks or UV damage. A $100 used cowling beats a $600 new one if it’s intact.

- Lower units (with proper inspection): A freshwater lower unit with 300 hours is a solid find if gears, shaft, and seals check out. I’ll cover inspections shortly.

- Tilt/trim assemblies: Mechanical parts you can test—cycle them, check for leaks, smooth movement, and corrosion on rams.

- Propellers: Check for bent blades, damaged hubs, spun inserts. Stainless props with light damage work as well as new if pitch and diameter match.

- Steering components (non-cable): Tilt tubes, brackets, helms are good used. Skip cables.

Which Route Fits Your Situation

- Engine age matters. A 2020 Suzuki 140HP justifies new OEM parts. A 2001 Mercury 75HP means used repairs are half your world.

- Usage frequency changes the math. Weekend lake cruiser with 30 hours a year? Used lower unit is fine if inspected. Offshore fishing 200 hours/year? New only. Downtime offshore isn’t just inconvenient—it’s a risk.

- Commercial vs recreational: Engines that earn money need uptime. A $1,200 fuel pump that runs 1,500 hours without fail beats three $400 used pumps that last 400 hours each and cost service trips.

- Budget and total cost: A used powerhead at $1,800 vs a new at $5,500 looks good—until you add $600 in seals, gaskets, pump replacement, and a $400 rebuild in 18 months. New with a 3-year warranty might cost $5,500 once; used might cost $5,000 over two years.

- Fuel economy: New 150HP 4-strokes burn ~12 liters/hour at cruise. Older carbureted 150HP burns 18 liters. At 100 hours/year and $4/gallon ($1.06/liter), that’s $636 in fuel saved annually, offsetting the new motor premium over time.

Where to Buy Matters

For new parts, stick to authorized dealers or manufacturers. We ship JLM marine parts worldwide. Our water pump kits match OEM specifications without dealer markups, costing around 30% less.

For used, trust marine salvage yards with physical locations and good reputations. They usually pressure-test lower units and run compression checks on powerheads before listing. Online platforms like eBay can work if you verify sellers and get serial number and internal component photos.

Avoid Craigslist and random sellers unless you can inspect personally. I’ve seen "good running lower units" with water in the gear oil and scored pinion gears.

OEM vs Aftermarket Quality

OEM parts meet the original manufacturer’s specs. A Honda thermostat fits and performs as designed. They cost 30-50% more than aftermarket equivalents.

Aftermarket parts range from junk to top-notch. Cheap $12 carb kits on Amazon use hardening rubber and undersized gaskets, causing air leaks. Don’t buy those.

Quality aftermarket like JLM ships parts made to OEM specs, often produced in the same factories under excess capacity. Our lower unit seal kits use 316 stainless springs and Viton rubber just like OEM but are 30-40% cheaper.

Vetting the aftermarket brand is key. Brands with no address, no engineering data, or reviews are risky. Brands with 20 years in business, global shipping, and return policies are trustworthy.

How to Inspect Used Parts Before Buying

Inspection is everything. Here’s what I check:

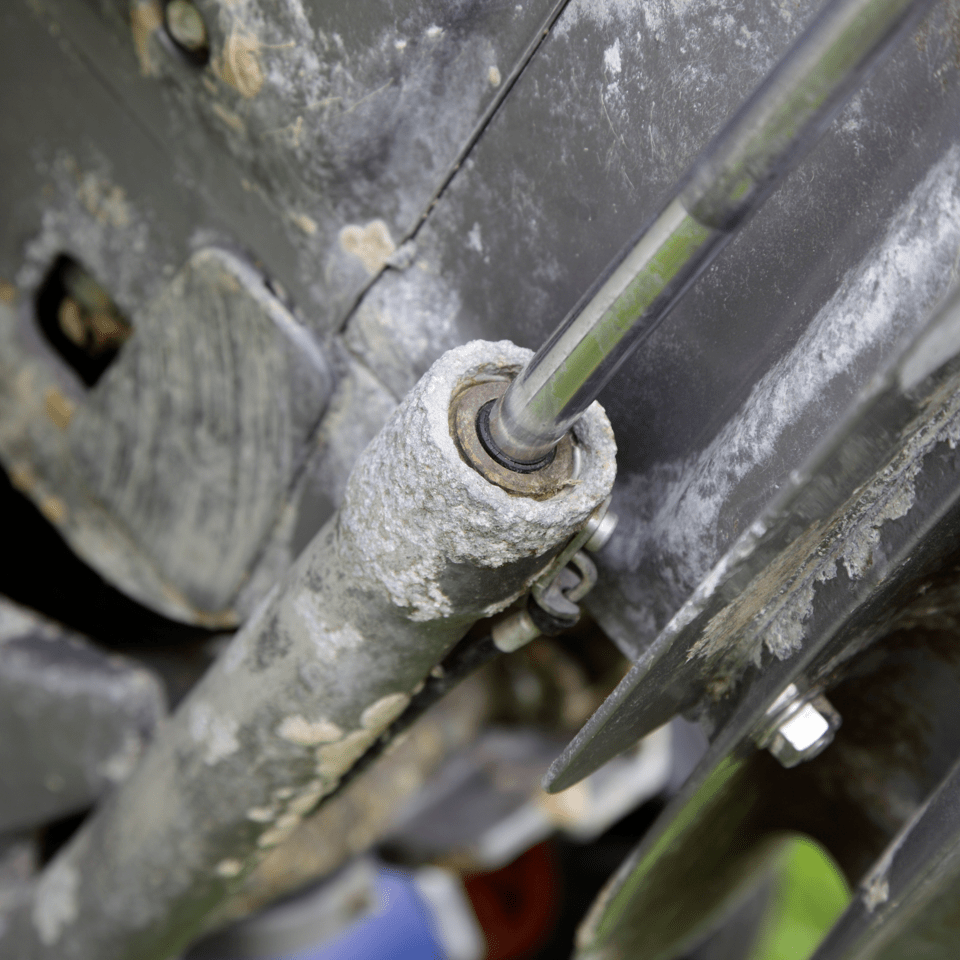

- Visual external: Look for cracks, especially near mounting points. Bent shafts, damaged splines, corrosion patches. White powder on aluminum is galvanic corrosion; deep damage means skip it.

- Corrosion deep-dive: Check behind anode plates, inside water passages, and mounting flanges. Probe suspect areas with a pick. Flakes or crumbles mean trash.

- Moving parts: For lower units, spin the prop shaft smoothly, no grinding or binding. Side play >1-2mm means worn bearings.

- Gear engagement: Shift through forward, neutral, reverse. Should engage cleanly, no grinding.

- Compression test (powerheads): Essential. Variation within 10% across cylinders. For example, 150-160 psi is good on a 115HP Yamaha. One cylinder at 110 psi is bad.

- Water pump housing: Remove faceplate if possible. Light surface marks are normal; deep grooves mean a new impeller will shred fast.

- Electrical parts: Test on running engine if possible. Stators should output 12-14V AC idle. ECU diagnostics should show no error codes. If seller won’t test, assume bad.

- Service history: Ask for logs. Low hour documented usage from freshwater is best. Saltwater means corrosion risk.

Maintenance After Installing Used Parts

Prep new-to-you parts to extend life:

- Clean thoroughly: Remove grease, dirt, salt. Hidden cracks can show up after cleaning.

- Replace wear items: Installing a used lower unit? Replace impeller and seals even if they look good. The impeller costs $35; dropping the lower unit again is $200 in labor. Used carbs? Replace diaphragms and gaskets.

- Lubricate well: Use marine-grade grease on splines, pivot points, and bearings. Use waterproof grease on tilt bushings and steering cable ends.

- Pressure test: For lower units, fill with gear oil, pump to 10 psi, and look for leaks. Leakage on the bench only worsens under load.

Common Questions

What are the main risks with used parts?

Hidden wear, invisible corrosion, unknown abuse, and zero warranty. Used parts might look fine but fail soon after install. Bent shift shafts or hairline cracks in powerheads are common hidden trouble.

Do new outboard parts always have warranty?

Most do. OEM parts usually offer 1-3 years. Yamaha gives 3 years on most components, Mercury similar. Quality aftermarket like JLM carries 1-2 years. Cheap generic aftermarket often has none.

How to tell if a used part is good?

Compression test powerheads with variation under 10%, inspect for cracks and corrosion; rotate lower unit shafts smoothly with minimal play; test electrical resistance and output on components like stators and ECUs. Service history is crucial.

Are used parts better environmentally?

Yes, if they last. Reuse keeps parts out of landfills and avoids manufacturing impact. But cheap used parts that fail early waste resources.

When to pick new over used?

For frequent, commercial, offshore, or safety-critical use; for engines under 10 years with parts available; and for internal engine components like seals and bearings. Downtime risk justifies new parts.

Practical Tip

Keep a basic toolkit aboard: metric and SAE socket sets, adjustable wrench, needle-nose pliers, flathead and Phillips screwdrivers, and a multi-tool. Half the minor problems you’ll encounter can be fixed in ten minutes with the right 10mm socket.

For a wide range of quality replacement parts, check out our boat accessories collection and water pump impeller options. Need fuel system components? Explore the fuel pump kits and fuel filter collection to keep your engine running clean.

Browse our full range of outboard motor parts to find OEM-quality and aftermarket upgrades for your setup.

For more guidance and parts, visit the JLM Marine home page to get everything direct from the factory with worldwide shipping.

Hi—I’m Jim Walker

I grew up in a Florida boatyard, earning pocket money (and a few scars) by rebuilding outboard carbs before I could drive. That hands-on habit carried me through a Ph.D. in mechanical engineering, where I studied how salt water quietly murders metal.

I spent ten years designing cooling systems for high-horsepower outboards, then joined JLM Marine as CTO. We bench-test every new part in the lab, but I still bolt early prototypes onto my own 23-foot skiff for a weekend shake-down— nothing beats real wake and spray for finding weak spots.

Here on the blog I share the fixes and shortcuts I’ve learned so your engine—and your day on the water—run smooth.

Para propietarios de embarcaciones:

Para ayudarlo a mantener y reparar sus motores marinos, esperamos que los siguientes recursos puedan serle de utilidad:

- Guía de números de serie de Mercury

- Manuales del propietario de Mercury

- Guía de referencia oficial de números de modelo en formato PDF de BRP

- Guía de números de serie de Johnson

-

Accesorios para barcos de JLM Marine

Acerca de JLM Marine

Fundada en 2002, JLM Marine se ha consolidado como un fabricante dedicado de piezas marinas de alta calidad, con sede en China. Nuestro compromiso con la excelencia en la fabricación nos ha ganado la confianza de las principales marcas marinas a nivel mundial.

Como proveedor directo, evitamos intermediarios, lo que nos permite ofrecer precios competitivos sin comprometer la calidad. Este enfoque no solo promueve la rentabilidad, sino que también garantiza que nuestros clientes reciban el mejor valor directamente del proveedor.

Estamos entusiasmados de ampliar nuestro alcance a través de canales minoristas, llevando nuestra experiencia y compromiso con la calidad directamente a los propietarios de embarcaciones y entusiastas de todo el mundo.

Leave a comment

Please note, comments need to be approved before they are published.