Propeller Slip or Engine Issue? When Your Boat Can’t Reach Speed

- What Causes High RPM with No Speed

- How the Propeller Hub Works (And Fails)

- Symptom Checklist

- Diagnosing a Spun Hub: Step-by-Step

- What a Spun Hub Does to Your Boat

- Repair or Replace?

- Torque Specs and Reassembly

- When It's Not the Hub: Other Causes of No Speed

- Calculating Propeller Slip

- DIY vs. Professional Repair

- Vintage and Pin-Drive Props

- Emergency Limp-Home Strategy

- Prop and Hub Maintenance Tips

Your boat's revving high but barely moving—engine screaming, GPS speed stuck at 15 mph when you should be pushing 35. First instinct is to blame the powerhead. Stop. Pull the prop first. Nine times out of ten, it's a spun hub, not your engine.

What Causes High RPM with No Speed

Spun propeller hub is the usual culprit. The rubber or plastic insert inside the hub slips on the driveshaft—shaft spins, prop doesn't. You get all the noise, none of the bite.

Propeller stall happens when you hammer the throttle before the hull picks up speed. Blade angle of attack gets too steep, thrust drops, and the prop just churns. As Steve Sandler notes, "If we hammer the throttles before the boat picks up sufficient speed, the velocity due to propeller rotation can become much greater than that due to boat advance. Angle of attack increases. If the angle of attack becomes too large, a stall condition occurs." Powerboating.com

Ventilation pulls air into the blade stream during sharp turns or chop. The prop spins faster in aerated water, loses density, loses push. Feels like slip but it's temporary.

Cavitation is a pressure drop creating vapor bubbles on the blades. Reduces efficiency, sounds like gravel in a blender.

Fouling—fishing line, weeds, barnacles—adds drag and kills bite. A prop wrapped in 20 feet of monofilament can't grab water.

How the Propeller Hub Works (And Fails)

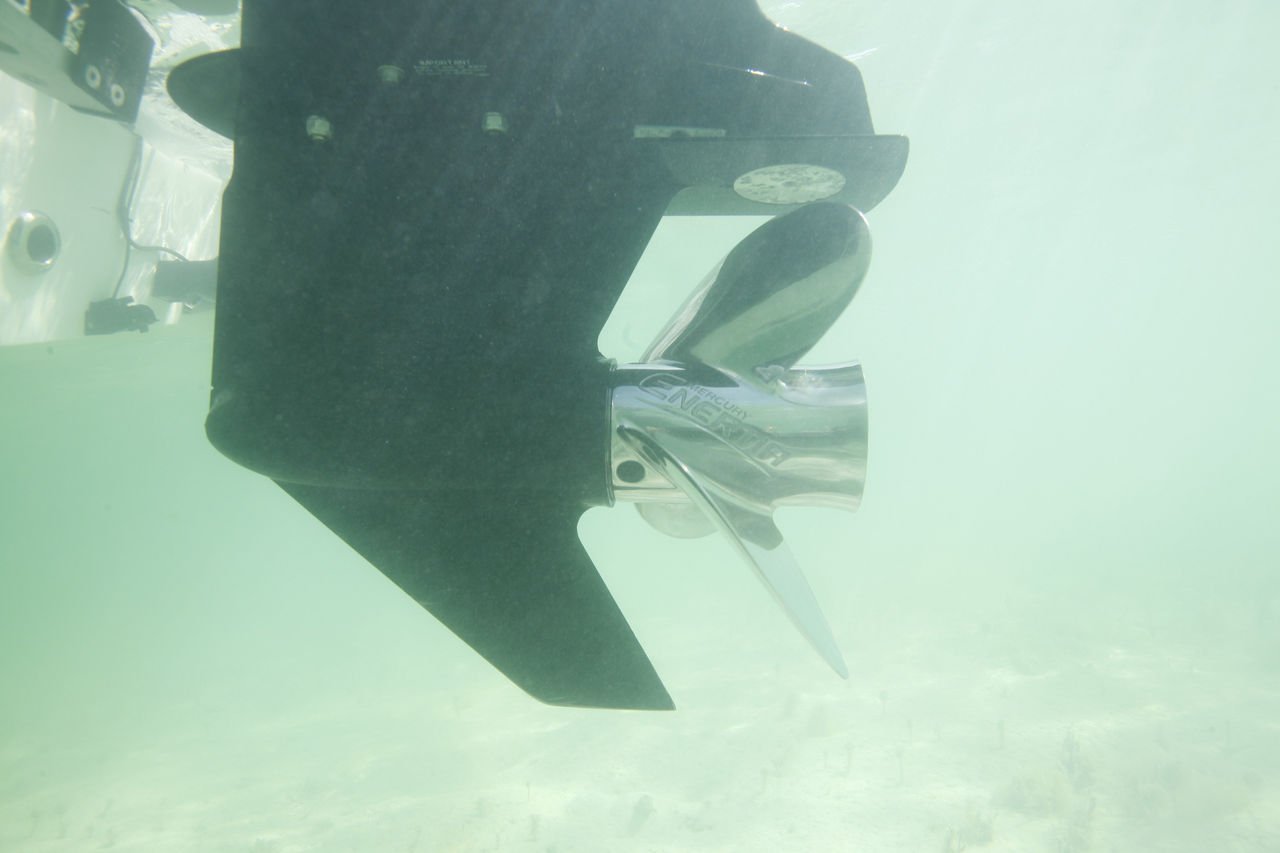

Most outboard and sterndrive props use a rubber or plastic sleeve inside the hub. It's a sacrificial shock absorber. Hit a stump, the hub slips instead of snapping your driveshaft or wrecking the lower unit gears.

Traditional pressed-in rubber hubs grip through compression and friction. When the rubber ages, dries out, or gets shocked hard, it separates from the inner splines or outer barrel. You get rotational slop—driveshaft turns, prop lags or freewheels.

Modern systems like Mercury Flo-Torq use drop-in plastic sleeves. They don't slip gradually; they shatter. One second you're planing, next you're dead in the water with pieces rattling inside the hub.

On a heavy pontoon boat, a spun hub feels like sluggishness—takes forever to get on plane, never quite gets there. On a lightweight bass boat, it's sudden: RPMs spike from 3000 to 5500 and speed stays flat. That's your clue.

You'll also smell it. Burning rubber is hard to miss. If you catch a whiff at the transom after a hard run, pull the prop.

Symptom Checklist

- Engine hits 5000+ RPM, GPS speed under 20 mph

- Burning rubber smell near the lower unit

- Slight movement at idle/low throttle, nothing at WOT

- No reverse thrust or weak reverse compared to forward

- Sudden loss of push after hitting debris or a sandbar

If you check three or more, inspect the hub before you do anything else.

Diagnosing a Spun Hub: Step-by-Step

Safety First

Disconnect the battery or pull the kill-switch lanyard. You don't want the engine starting while you're working the prop. Keep your hands clear of the blades.

Remove the Propeller

You'll need a prop wrench (usually 1-1/16" socket for most outboards), a prop block or chunk of 2x4 to wedge the blades, and a breaker bar if the nut is seized.

Slide the prop block between two blades to lock rotation. Break the prop nut loose—it's torqued to 55-60 ft-lbs on most motors, so expect resistance. Once the nut is off, slide the prop straight off the shaft.

Check the thrust washer. It's a small metal or plastic disc that sits behind the prop. If it's stuck on the shaft or fell into the lower unit, fish it out. Reassembling without it ruins the lower unit casting.

The Mark-and-Inspect Method

Take a piece of chalk, a paint pen, or a file and make a clear line across the face of the hub and onto one of the propeller blades. The line must cross the boundary between the rubber/plastic insert and the metal prop body.

Slide the prop back onto the splines. Do not torque the nut yet—just snug it hand-tight so the hub is seated.

Here's the part most guides skip: you can't confirm a spun hub cold. The rubber still has some residual friction. Manual rotation often won't show slip until it's under load and hot.

The Water Test

Put the boat in the water. Run it in forward gear at about half throttle for 30 seconds, then shut down. Pull the prop again and check your marks. If the line is broken—prop body rotated relative to the hub—it's spun. If the marks still align perfectly, the hub is intact.

If you don't want to launch, you can sometimes force it by hand: hold the prop with both hands and try to twist it hard relative to the hub. A failed hub will turn with enough force. A good one won't budge.

What a Spun Hub Does to Your Boat

At idle or low throttle, you might get weak forward movement—enough to limp back to the ramp at 5 mph and 1000 RPM. Boaters call this "get-home mode." The slipping hub still transfers a tiny bit of torque.

Push the throttle past 2000 RPM and the slip gets worse. Engine hits the rev limiter around 6200 RPM (check your manual), but boat speed plateaus at 12 mph. You're working the engine hard, burning fuel, risking over-rev damage if you keep the throttle pinned.

The heavier the prop, the worse the problem. Stainless steel props weigh more and flex less than aluminum, so they put more stress on the hub under shock load. If you run stainless and you hit something, expect hub failure before blade damage.

Repair or Replace?

Re-Hubbing the Prop

If the prop body and blades are straight, re-hubbing is the cheaper fix. Hub kits run $50 to $150 depending on brand and material.

Drop-in plastic sleeve kits (Flo-Torq, Solas Rubex, etc.) are DIY-friendly. You slide out the old sleeve, clean the bore, and press in the new one by hand or with a rubber mallet. No special tools, 15 minutes.

Pressed-in rubber hubs need a hydraulic press. Most shops charge $75-$150 for press work. You can try driving it out with a socket and hammer, but you risk cracking the prop barrel.

Tools for a DIY hub swap:

- Pick or small screwdriver (to pry out retaining rings)

- Rubber mallet

- Marine grease (for the splines—don't skip this)

- Torque wrench

One YouTuber replaced a Quicksilver hub on Smith Mountain Lake mid-tournament using a pick, screwdriver, and a 1-1/16" socket. Took him 20 minutes dockside. YouTube case

Buying a New Propeller

If the prop has bent blades, deep nicks, or the barrel is cracked, replace it. Aluminum props cost $150-$500. Stainless steel runs $300-$1,200.

Stainless lasts longer, resists damage better, and holds speed in rough water. Aluminum is cheaper and easier on the hub when you hit debris—it bends before the hub fails, sometimes saving both.

Match the prop to your engine's horsepower, gear ratio, and intended use. A 25-pitch prop on a 90 HP motor might be perfect for speed, terrible for pulling skiers. Check your engine manual for the factory spec, then adjust pitch based on actual WOT RPM.

Your motor should hit the manufacturer's wide-open-throttle RPM range (usually printed on the cowling, like 5000-5800 RPM). If it's under, drop a pitch size. If it's over, go up.

We stock hub kits and props for Mercury, Yamaha, Suzuki, Honda, and Evinrude. Not sure which fits? Email us a photo of your hub and the engine model—saves you from ordering the wrong part. We've shipped correct-fit hubs to customers in Australia, Canada, and across the US because getting it right the first time matters more than saving two bucks on a generic kit. Check out our direct from factory boat parts collection for options.

OEM vs. Aftermarket Hubs

OEM hubs are reliable but overpriced. You're paying $120 for a $60 part because of the logo.

Cheap aftermarket hubs—the $15 kits from random online sellers—use hard rubber that doesn't compress right. Fitment is sloppy. You'll tear the lower unit apart again in six months.

Quality aftermarket (brands like Solas, Turning Point, and our JLM kits) come from the same factories that supply OEM contracts. Same spec, same material, half the price. Factory-direct sourcing cuts the dealership markup without sacrificing fit or durability. Browse our boat accessories collection for quality marine parts.

Torque Specs and Reassembly

When you reinstall the prop, grease the splines with marine-grade waterproof grease. Keeps corrosion down, makes the next removal easier.

Torque the prop nut to spec—usually 55-60 ft-lbs for most outboards, but check your manual. Under-torquing lets the prop walk off the shaft. Over-torquing crushes the hub or cracks the nut.

Install a new cotter pin or lock tab. Don't reuse the old one.

When It's Not the Hub: Other Causes of No Speed

If the hub checks out but you're still not hitting speed, work through these:

Prop Shaft and Seal

Pull the prop and inspect the shaft for fishing line. Line cuts through the rubber seal behind the prop, letting water into the lower unit. You fix the hub, then grenade the gears a week later because the case filled with water.

Fouling

Barnacles, weeds, or slime on the hull and lower unit add drag. A fouled hull can raise total resistance by 52% in bad cases. Riviera Maritime Media

Scrub the bottom. Pull the boat and pressure-wash the hull, inspect the prop, clean the lower unit. You'd be surprised how much speed you lose to a quarter-inch of slime.

Fuel and Air Restrictions

Clogged fuel filter, kinked fuel line, or a vent-blocked tank starves the engine. You get high RPM for a few seconds, then it falls off as the carbs run dry. For quality replacement parts, check our fuel filter collection and fuel pump options.

Blocked air intake (wasp nest in the cowl, clogged flame arrestor) does the same thing. Pull the cover, check the filter, clear the intake.

Ignition and Spark

Bad coil, fouled plugs, or a failing stator cuts power. The engine runs but won't make full RPM under load. Swap plugs, test coils, check the charging system.

Incorrect Engine Height and Ventilation

If the anti-ventilation plate sits too high, the prop sucks air during acceleration—RPMs spike, boat doesn't plane. One Whaler owner in Huntington Beach couldn't get his 130 Super Sport on plane with a 40 HP Mercury until he raised the engine height and switched to an 11-pitch stainless prop. Instant planing, no porpoising. Continuous Wave forum

Lower the engine in 1/2" increments until the plate is level with or just above the hull bottom.

Calculating Propeller Slip

If you want numbers, measure slip with this formula:

Theoretical speed (mph) = (RPM × Pitch in inches) / (Gear Ratio × 1056)

Then:

Slip % = 100 × (Theoretical Speed - Actual GPS Speed) / Theoretical Speed

Normal slip for a planing hull at WOT is 8-12%. Heavy boats or pontoons might run 10-15%. Surface drives can be as low as 4-8%. Prop Depot Teague Custom Marine

If you're seeing 25% or higher, something's wrong—spun hub, damaged blades, wrong pitch, or severe fouling.

Slip is highest during the transition to plane, drops as speed increases. If slip stays high at WOT, that's your diagnostic flag.

DIY vs. Professional Repair

You can handle most hub swaps and basic diagnostics at home. Drop-in hubs, prop removal, visual inspection—these are shade-tree jobs.

Send it to a shop if:

- The prop nut is seized (heat and impact tools required)

- You need a pressed rubber hub replaced (hydraulic press)

- The lower unit took a hard hit and you suspect internal gear or shaft damage

- You're not confident with torque specs or spline alignment

A good marine mechanic will diagnose in 20 minutes, tell you if it's the hub, the prop, or something deeper. Shop labor runs $100-$150/hour in most US markets, but it beats ordering the wrong part three times or damaging the lower unit trying to force a stuck prop.

Vintage and Pin-Drive Props

Older outboards—pre-1980s motors, some small kickers—use shear pins instead of rubber hubs. A soft brass or aluminum pin connects the prop to the shaft. Hit something, the pin shears, prop freewheels.

If you've got a vintage rig and you lose drive, check for a broken shear pin before you tear into the hub. Carry spares, a drift punch, and a hammer. Field fix takes five minutes.

Emergency Limp-Home Strategy

If the hub spins and you're stuck offshore, keep RPM under 1500. The failed hub will still transfer a tiny bit of torque at low speed. You'll move at 3-5 mph, but you'll move.

Don't pin the throttle. High RPM with a spun hub just heats the rubber, makes the slip worse, and risks over-revving the engine into the limiter. Idle speed, patient run back to the ramp.

Prop and Hub Maintenance Tips

Carry a spare hub kit. It's a sacrificial part, like a fuse. If you run hard, hit debris, or fish shallow water, assume you'll spin one eventually. A $70 kit in the toolbox beats a tow bill.

Inspect the prop every few trips. Pull it, check the hub for cracks or separation, grease the splines, check the thrust washer. Takes ten minutes, catches problems early.

Flush with fresh water after every saltwater run. Salt corrodes the splines, seizes the prop nut, and degrades the rubber. A five-minute flush saves an hour with a grinder trying to cut the nut off later.

After you hit something—stump, sandbar, crab pot—pull the prop that day. Check for blade damage, hub slip, and fishing line on the shaft. A small impact might not show symptoms immediately, but the hub can fail two trips later under load.

For more marine parts and accessories to keep your boat running and ready, visit our JLM Marine hub.

Leave a comment

Please note, comments need to be approved before they are published.