Why Is My Outboard Losing Power? Top 5 Causes

Your outboard revs high but the boat barely moves. Or it bogs down when you hit the throttle. Sometimes it runs fine for a few minutes, then cuts power mid-run. After 20 years wrenching on these engines, I can tell you it usually comes down to five things: fuel starvation, weak spark, a slipping prop, overheating, or something choking the air intake.

Start with the simplest checks first. Most power loss issues don't need a full teardown—just methodical diagnosis. Here's what actually causes these problems and how to fix them.

1. Spun Propeller Hub

When the rubber hub inside your prop fails, it disconnects the engine's rotation from the propeller blades. The engine screams at 5000 RPM, but the boat crawls. You get all the noise, almost none of the thrust.

This happens after hitting a rock, log, or sand bar. The impact shears the rubber. Sometimes it's gradual—months of hard acceleration can cook the hub until it finally lets go.

How to diagnose it: Kill the engine. Pop it in neutral. Try rotating the prop by hand relative to the hub. If it spins freely or has any slop, the hub is shot. Compare RPM to actual boat speed—if you're turning 5500 RPM but only making 20 mph when you should be hitting 35, that's a classic spun hub.

You can calculate prop slip to confirm. Measure your actual speed with GPS, check your RPM with a tachometer, then compare against your prop's theoretical speed based on pitch. Anything over 15-20% slip usually means a failed hub.

The fix: Replace the prop. Don't try to repair the hub—it won't hold. When choosing a replacement, match the pitch and diameter to your engine's spec. A 15-inch pitch prop that's spun won't magically work better as a 17-inch. For common motors like Yamaha F150 or Mercury 90hp, this is a straightforward swap you can do dockside with a prop wrench and a block of wood to hold the blades. If you suspect lower unit damage from the same impact, get a mechanic to inspect the gears before you just bolt on a new prop.

2. Fuel System Blockage or Air Leaks

Restricted fuel flow is the number one cause we see for power loss under load. The engine idles fine because fuel demand is low. But when you push the throttle and the cylinders need more fuel, a clogged filter or kinked line can't deliver. The engine bogs, surges, or just refuses to rev past 3000 RPM.

Clogged fuel filter: Your inline filter is a clear canister, usually mounted between the tank and the engine. Look for brown sediment, water droplets, or any discoloration. If you see debris, the filter is done. According to marine service data, contaminated fuel causes nearly 40% of outboard failures, especially in humid coastal states where water infiltration is common. Consider replacing your fuel filter regularly to maintain optimal flow.

Ethanol fuel is brutal. E10 gas absorbs moisture from the air. If it sits in your tank for more than 30 days, phase separation starts—the ethanol pulls water and sinks to the bottom of the tank. Your engine sucks up this water-ethanol mix, and combustion stops. The remaining gasoline also loses octane, which can cause detonation and power loss even if the water hasn't reached the engine yet. Use a fuel stabilizer with every fill-up if your boat sits more than a few weeks between runs.

Air leaks in the fuel line: An air leak between the tank and the fuel pump lets the engine pull air instead of liquid fuel. This creates a lean condition—too much air, not enough fuel. Symptoms include sputtering, surging, and that weird "slipping" feel when you accelerate.

Inspect every connection while the engine is running. Look at the clear primer bulb—if you see air bubbles cycling through, there's a leak upstream. Check where the hose clamps attach at the tank, the filter, and the engine. Old rubber lines crack after a few years, especially the non-EPA compliant hoses from pre-2011 motors. Newer low-permeation fuel lines can also fail internally—the inner liner delaminates and restricts flow without any visible external damage. If your lines are over five years old and the primer bulb won't stay firm, replace the whole run.

Primer bulb test: Squeeze the bulb. It should get rock-hard and stay that way for at least 30 seconds. If it softens immediately, you've got a leak or a weak fuel pump.

3. Ignition System Failure

A fouled spark plug or corroded plug wire kills that cylinder's contribution to power. At idle, the engine can run on three cylinders and you might not notice. Under load, that dead cylinder is a 25% power loss on a four-cylinder engine.

Spark plug condition: Pull the plugs. A healthy plug has a light tan to grayish-brown electrode.

- Black, sooty carbon: Rich fuel mixture. Common if you spend a lot of time trolling at low RPM. The engine never gets hot enough to burn off the deposits.

- White or blistered ceramic: Lean mixture or overheating. This can indicate an air leak, wrong plug heat range, or a cooling issue.

- Aluminum specs on the electrode: Pre-ignition. The piston is so hot it's literally melting and depositing metal on the plug. Stop running the engine immediately—this will destroy the piston.

Check the gap with a wire gauge. Most outboards spec 0.035-0.040 inches, but verify in your service manual. A gap that's too wide weakens the spark. Too narrow and you get incomplete combustion.

Spark plug wires: Saltwater eats the terminals. Pull the boot off the plug and inspect the metal contact inside. If you see white or green corrosion, or if the terminal is crumbling, replace the wire. You can test resistance with a multimeter—good marine-grade wire should read between 3,000-12,000 ohms per foot depending on type. Anything higher and you're losing spark energy as heat in the wire instead of delivering it to the plug.

High-resistance wires cause misfires under load that don't show up at idle. The ignition system can push enough voltage to jump the gap when demand is low, but when you're at wide-open throttle and cylinder pressure is high, the weak spark can't ignite the compressed mixture.

Replace plugs every 100 hours or annually, whichever comes first. It's cheap insurance. Use the manufacturer's specified plug—NGK, Champion, or whatever your engine was designed for. The heat range matters. Running a plug that's too cold will foul quickly. Too hot and you risk pre-ignition.

4. Overheating and Cooling System Issues

Outboards use raw water cooling. They suck water from the lake or ocean, pump it through the engine block, and spit it out the telltale (that little stream that shoots out above the waterline). If that system fails, the engine overheats and either goes into limp mode or loses power from heat-related detonation.

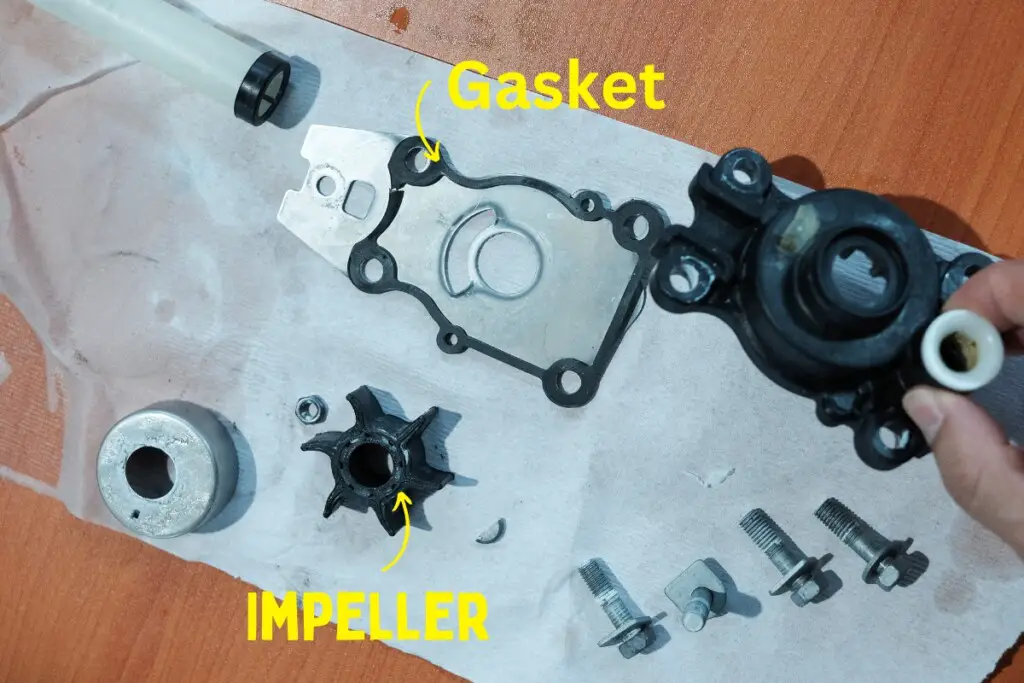

Check the telltale stream: With the engine running, look for a solid, steady stream of water. It should spit strongly at idle and increase with RPM. If it's weak or dribbling, you've got a restriction or a failing water pump. Replacing your outboard's water pump impeller on schedule is crucial to prevent overheating issues.

Clogged water intake: The intake screens on the lower unit are the first place to check. Seaweed, plastic bags, and sand can block the ports. Kill the engine, tilt it up, and inspect the intakes. Clear any debris.

Failed impeller: The rubber impeller inside the water pump housing has flexible blades that push water through the system. Rubber degrades. The American Boat and Yacht Council (ABYC) recommends replacing the impeller every 300 hours or two years, whichever comes first, even if it looks fine. The compound deteriorates from heat cycling and sitting dry between uses.

Symptoms of a bad impeller: The telltale stream is weak or intermittent, the engine runs hot, and you might see steam mixed with the water output. If you've been running the engine hard and notice a sudden drop in the telltale flow, shut it down immediately. Running without coolant flow will warp the cylinder head in minutes.

Stuck thermostat: The thermostat regulates engine temperature. If it sticks closed, coolant can't circulate and the engine overheats. If it sticks open, the engine runs too cold, which reduces combustion efficiency and can cause rough running. A thermostat stuck open is less common but can mimic power loss symptoms because the fuel mixture doesn't burn completely in a cold engine. For detailed guidance, see our article on thermostat maintenance.

Thermostats seize from corrosion, especially if you don't flush the engine with fresh water after saltwater use. Always flush after every ride—this simple step prevents stuck thermostats, clogged passages, and seized water pumps.

Thermal relief valve: Some engines have a pressure relief valve that dumps excess cooling water if the system overheats. If this valve fails open, it bypasses too much water and the engine can't reach operating temperature. Symptoms are subtle—rough idle, poor fuel economy, and sluggish acceleration. It's not common, but if you've ruled out the thermostat and the engine is running unusually cool, inspect the relief valve.

5. Air Intake or Carburetor Restrictions

The engine needs clean air to mix with fuel. If the air intake is blocked or the carburetor jets are clogged, combustion suffers and power drops.

Blocked air intake: The air filter or flame arrestor can get clogged with dirt, oil, or debris. A partially restricted intake leans out the mixture at high RPM—the engine can't pull enough air to match the fuel being delivered. This causes hesitation and power loss under load. Remove the air filter and inspect it. If it's oil-soaked or packed with dirt, replace it or clean it per the manufacturer's instructions.

Clogged carburetor jets: Carburetors meter fuel through tiny brass jets. Varnish from old fuel, dirt, or corrosion can partially block these passages. At idle, the idle circuit might flow enough fuel to keep the engine running. But when you open the throttle and the main jet needs to deliver fuel for full power, a restriction kills performance.

Symptoms of a dirty carb: The engine starts fine, idles reasonably well, but bogs or hesitates when you accelerate. It might also surge at cruising speed or refuse to reach full RPM.

Carburetor cleaning: Disassemble the carb. Soak the body and jets in carburetor cleaner. Use compressed air or fine wire to clear every passage—don't skip the tiny bleed holes. Replace all gaskets and O-rings during reassembly. Old gaskets leak air, which throws off the fuel mixture. A complete rebuild kit includes jets, gaskets, float needle, and diaphragms. We offer quality carburetor and carburetor repair kits to help you restore your engine's performance.

If you run ethanol fuel, carburetor varnish builds up faster. We've seen carbs gummed solid after just one season of sitting with untreated fuel in the bowl. Drain the carb if you're storing the boat for more than a month.

Idle mixture screw adjustment: The idle mixture screw controls the air-fuel ratio at low RPM. If it's turned in too far, the mixture is too lean and the engine will stumble when you transition from idle to throttle. Adjustment procedure varies by engine, but generally you turn the screw out until the engine runs smoothly, then back it in 1/8 to 1/4 turn. Use a tachometer to verify the idle RPM stays within spec during adjustment.

Idle Air Control (IAC) valve (EFI engines): Electronic fuel injection systems use an IAC valve to manage airflow at idle. If the valve gets dirty or the stepper motor fails, idle becomes erratic and throttle response suffers. Remove the IAC valve and clean the pintle and bore with throttle body cleaner. If cleaning doesn't fix it, replace the valve.

Fuel tank vent: Your tank needs to breathe. As fuel is drawn out, air replaces it. If the vent cap is clogged or the vent line is kinked, a vacuum builds in the tank and fuel flow stops. The engine will run fine for a few minutes, then start starving for fuel. Loosen the fuel cap—if you hear a rush of air, the vent is blocked. Clean the vent or replace the cap.

Quick Diagnostic Checklist

Start here before you tear anything apart. Work from easiest to hardest.

Kill switch lanyard: Confirm it's fully seated. A partially disengaged lanyard can cut power intermittently. More about the importance of the kill switch.

Fuel system:

- Squeeze the primer bulb. Does it firm up and stay hard? If it stays soft or you see air bubbles, you have a fuel delivery problem.

- Inspect the inline fuel filter for debris, water, or discoloration. Replace if dirty.

- Check all fuel line connections at the tank, filter, and engine for cracks or loose clamps.

- Smell the fuel. If it's stale or smells like varnish, drain the tank and refill with fresh gas plus stabilizer.

Propeller:

- Visually inspect for bent blades, dings, or fishing line wrapped around the shaft.

- With the engine off and in neutral, try rotating the prop by hand. Any slop or free rotation means a spun hub.

Ignition system:

- Remove the spark plugs. Check the color, gap, and electrode condition. Replace if fouled or worn.

- Inspect the plug wires and boots for cracks or corrosion.

Cooling system:

- Start the engine and check the telltale stream. It should be strong and steady.

- Tilt the engine and inspect the water intake screens on the lower unit for blockage. For detailed guidance on the cooling system parts, including water pumps and impellers, visit our online parts collections.

Compression test (if the above checks pass):

- Use a compression gauge on each cylinder. Healthy compression is generally above 100 PSI, with less than 10% variance between cylinders. Low compression points to worn rings, scored cylinder walls, or valve issues—internal engine problems that need a professional.

When to Call a Mechanic

Some problems require specialized tools or deep mechanical knowledge. If you've gone through the checklist and the issue persists, stop. Here's when to hand it off:

- Low or uneven compression: Internal engine wear. This needs a teardown and rebuild.

- Unusual engine noises: A hollow knocking sound indicates piston slap or worn bearings. A high-pitched whining can be a fuel pump bearing failure or gearcase issue. Grinding means gear damage in the lower unit.

- Intermittent problems you can't replicate: Electrical gremlins, failing sensors, or ECM issues require a diagnostic scanner and experience reading fault codes.

- You don't have the right tools: Compression gauge, multimeter, timing light, or specialized pullers for the flywheel and lower unit.

Choosing a mechanic: Ask other boaters at your marina for recommendations. Look for someone with specific experience on your engine brand—Yamaha, Mercury, Suzuki, or whatever you run. Certifications from ABYC (American Boat and Yacht Council) indicate a commitment to industry standards for wiring, fuel systems, and safety. A good tech will explain the diagnosis, show you the failed part if possible, and give you a written estimate before starting the repair.

For additional resources and parts, explore our full JLM Marine marine parts collection.

2-Stroke vs. 4-Stroke Differences

Power loss causes vary slightly depending on your engine type.

2-stroke specific issues:

- Reed valves: These thin metal or carbon fiber flaps control airflow into the crankcase. If they crack, chip, or don't seal properly, you lose compression and the engine won't build power. Symptoms include poor acceleration and low top speed. Inspect the reeds through the intake port—look for cracks, bent petals, or carbon buildup preventing a tight seal.

- Oil injection system failure: 2-strokes mix oil with fuel for lubrication. If the oil pump fails, the engine runs without lubrication and seizes within minutes. If you smell raw gas without the usual oil smell, or if you see blue smoke stop suddenly, check the oil reservoir and pump operation immediately.

4-stroke specific issues:

- Low engine oil level: 4-strokes have a separate oil sump. If the level drops (from leaks or neglect), the engine can go into a protection mode that limits RPM to prevent damage. Check the dipstick before every run.

- Valve lash out of spec: Over time, valve clearances change. If the lash is too tight, the valves don't close fully and compression drops. Too loose and the valves don't open enough, restricting airflow. Valve adjustment requires feeler gauges and following the service manual's procedure—usually every 100-300 hours depending on the manufacturer.

Understanding Limp Mode

Modern outboards have Engine Control Modules (ECM) that monitor sensors for oil pressure, temperature, and RPM. If a sensor detects a fault—like overheating, low oil, or an electrical short—the ECM cuts power to protect the engine. This is called limp mode or safe mode.

Symptoms: The engine suddenly drops to idle or won't rev past 2000-3000 RPM. You might see a warning light or hear a steady beep.

Common triggers:

- Overheating (failed impeller, clogged intake, stuck thermostat)

- Low oil pressure (4-stroke engines)

- Faulty oil pressure sensor (false alarm—sensor reads low pressure even when oil flow is fine)

- Faulty temperature sensor (sensor fails and reports overheating even when the engine is cool)

Diagnosis: If you suspect limp mode, check the telltale stream first. If water flow is strong and the engine isn't actually hot, the issue might be a bad sensor. A mechanic with a diagnostic scanner can read the fault codes stored in the ECM and pinpoint the exact sensor or system causing the shutdown.

After checking all the systems above, if you still have power loss and no fault codes, the next step is load testing. Revving the engine in neutral proves nothing—it needs to be under load to diagnose most power issues. Either test on the water at full throttle or use a properly sized prop to load the engine on a stand or dynamometer.

Keep fresh fuel in your tank, replace your impeller on schedule, and check your plugs every season. Most power loss comes down to neglecting the basics.

Sources:

[1] https://partsvu.com/blogs/boating-resources/what-causes-a-boat-motor-to-lose-power

[2] https://www.rjnautical.com/blog/common-causes-of-outboard-motor-failure-how-to-avoid-them/

[3] https://www.pbo.co.uk/expert-advice/expert-answers/loss-of-engine-power-under-load-expert-advice-to-solve-the-problem-75406

[4] https://www.boatingmag.com/top-10-reasons-boats-break-down-0/

[5] https://jlmmarine.com/blogs/outboard-101/outboard-engine-lifespan-plummeting-here-are-the-5-fatal-damage-causes

[7] https://boatengine.com/how-to-fix-loss-of-power-on-your-outboard-today/

[8] https://www.wavetechpowersports.com/the-causes-of-boat-motor-power-lose

[9] http://fishwrecked.com/forum/losing-power-under-load-problem-solved

[21] https://jlmmarine.com/blogs/outboard-101/outboard-engine-bogging-down-how-to-troubleshoot-low-rpm-idle-issues-on-water

Additional helpful links for parts & support at JLM Marine:

Hi—I’m Jim Walker

I grew up in a Florida boatyard, earning pocket money (and a few scars) by rebuilding outboard carbs before I could drive. That hands-on habit carried me through a Ph.D. in mechanical engineering, where I studied how salt water quietly murders metal.

I spent ten years designing cooling systems for high-horsepower outboards, then joined JLM Marine as CTO. We bench-test every new part in the lab, but I still bolt early prototypes onto my own 23-foot skiff for a weekend shake-down— nothing beats real wake and spray for finding weak spots.

Here on the blog I share the fixes and shortcuts I’ve learned so your engine—and your day on the water—run smooth.

For Boat Owners:

To assist you in maintaining and repairing your marine engines, we hope the following resources may be of use:

- Mercury Serial Number Guide

- Owner's Manuals from Mercury

- Official Model Number Reference Guide PDF from BRP

- Johnson Serial Number Guide

-

Boat Accessories from JLM Marine

About JLM Marine

Founded in 2002, JLM Marine has established itself as a dedicated manufacturer of high-quality marine parts, based in China. Our commitment to excellence in manufacturing has earned us the trust of top marine brands globally.

As a direct supplier, we bypass intermediaries, which allows us to offer competitive prices without compromising on quality. This approach not only supports cost-efficiency but also ensures that our customers receive the best value directly from the source.

We are excited to expand our reach through retail channels, bringing our expertise and commitment to quality directly to boat owners and enthusiasts worldwide.

Leave a comment

Please note, comments need to be approved before they are published.