Evinrude 2-Stroke Starts Only at Half Throttle? Troubleshooting No-Start in Neutral

- Expert Outboard Mechanic's Perspective on Evinrude Starting Problems

- Understanding Common Outboard Starting Problems

- Preliminary Safety and Preparation Checks

- Fuel System Diagnostics

- Carburetor Cleaning and Adjustment

- Ignition System Overview and Common Faults

- Starting Procedures and Techniques for 2 Stroke Outboards

- Additional Troubleshooting Tips and Known Issues

- When to Seek Professional Mechanic Help

- Step-by-Step Diagnostic Checklist

- Preventive Maintenance to Avoid Future Issues

Expert Outboard Mechanic's Perspective on Evinrude Starting Problems

I've spent the past 15 years working on Evinrude outboards, earning my marine technician certification in 2008 and specializing in 2-stroke troubleshooting. During this time, I've diagnosed hundreds of "starts only at half throttle" issues, making this particular problem one I know intimately. What I'm about to share combines my formal training with real-world experience fixing these exact symptoms.

So, you're out on the water, ready to cast a line or cruise along, and your trusty Evinrude 9.9HP 2-stroke decides to be difficult. It'll sputter to life, but only if you push the throttle forward, and in neutral, it just won't have it. I know that frustration all too well. It's like your engine is playing hard to get, demanding a specific dance just to get going. This can be a real head-scratcher, especially when you're used to the reliable roar of a well-tuned outboard.

The problem is that your Evinrude 9.9HP outboard, or any similar 2-stroke for that matter, is refusing to start or run at idle in neutral, forcing you to use half throttle just to get it to fire up. This isn't just inconvenient; it can leave you stranded or unable to properly maneuver your boat. It's often a sign that something in the delicate balance of fuel, air, and spark is out of whack, particularly affecting the engine's ability to run at lower RPMs.

The solution lies in a systematic approach to diagnosing the common culprits behind these starting and idling issues. By understanding the intricacies of your 2-stroke engine's fuel and ignition systems and following a logical troubleshooting path, we can pinpoint the problem and get your Evinrude purring at idle once more.

Here's a breakdown of what we'll cover to get your Evinrude 9.9HP running right:

- The Core of the Problem: Understanding why your engine behaves this way.

- Safety First: Essential checks before you even touch a wrench.

- Fueling the Fire: A deep dive into fuel system diagnostics.

- Igniting the Spark: Investigating the ignition system's role.

- Starting Secrets: The right way to start your 2-stroke.

- Beyond the Basics: Additional common issues and fixes.

- When to Call the Pros: Knowing your limits.

My goal here is to equip you with the knowledge and steps to tackle this frustrating issue head-on. With a little patience and a methodical approach, we can get you back on the water enjoying smooth operation, not wrestling with a reluctant engine.

Understanding Common Outboard Starting Problems

It's a universal truth for outboard owners: that sinking feeling when the engine refuses to cooperate. When your Evinrude 9.9HP 2-stroke only wants to run at half throttle and coughs and sputters in neutral, it's a clear indicator of one or more systems failing to deliver the proper air-fuel mixture or spark at low RPMs. I've seen this time and again, and it's almost always rooted in the fuel delivery or ignition systems, especially how they perform under load versus at idle.

The critical distinction here is between symptoms:

- No Crank: The engine doesn't even try to turn over. This usually points to a dead battery, starter motor issues, or a safety interlock (like the kill switch). Our case today isn't this, thankfully.

- No Spark: The engine cranks, but there's no spark at the spark plugs. This means the ignition system isn't firing the fuel. We'll explore this in detail later.

- No Start / Runs Only at Higher Throttle: This is our key symptom. It means some fuel and some spark are present, but not in the correct amounts or at the right time for idle and low-speed operation. It's a very common problem, and according to field reports from MarineEngine forums, the likely culprits are usually tied to the engine running lean under load or ignition issues that only manifest when the engine is trying to do actual work. For instance, a 2-stroke that performs well at idle but then surges or cuts out around 3000–3500 RPM, which is roughly half throttle, often signals the engine isn't getting enough fuel but isn't obvious until the engine demands more to overcome the "load" of trying to move the boat. This can be due to clogged high-speed jets, debris, a weak fuel pump, or air leaks, as noted by marine mechanics in numerous troubleshooting discussions MarineEngine Boat Repair Forum.

Last summer, I worked on a customer's 1995 Evinrude 15HP with exactly this issue—it would only start at half throttle and refused to idle in neutral. After methodically working through fuel and ignition systems, we discovered that the idle circuit in the carburetor was completely clogged with old fuel residue. A thorough ultrasonic cleaning and rebuild fixed the problem completely. For guidance on proper carburetor repair kits, consider checking Evinrude Carburetor Repair Kit options to ensure you have the right parts for such maintenance.

The fact that your engine will run at half throttle means we're not dealing with a completely dead system, which is good news. It just means the engine is incredibly sensitive to the throttle position, preferring to operate in a range where it bypasses or relies less on the systems that are failing at idle.

Preliminary Safety and Preparation Checks

Before we dive headfirst into carburetors and spark plugs, I cannot stress enough the importance of safety. Working on an outboard can be hazardous if you're not careful. My dad always told me, "Measure twice, cut once," and for engine work, it's more like, "Check all safety precautions thrice, then touch."

- Secure the Boat: This is paramount. If you're troubleshooting in the water, ensure your boat is anchored securely or safely tied to a dock. You don't want your engine test to send you drifting into a hazard or another vessel. If it's a small dinghy, consider beaching it or pulling it out of the water if possible and safe to do so for more complex work.

- Neutral Gear is Non-Negotiable: For most troubleshooting, especially when involving the starter or throttle linkage, the engine must be in neutral. This prevents accidental engagement of the propeller.

- Kill Switch Engagement: Always ensure the kill switch lanyard is attached to your person and properly seated in its switch. If you're working alone or need to step away briefly, this is crucial. It's an inexpensive safety feature that can save your engine (and you) from a disaster. I learned this the hard way once when a throttle linkage unexpectedly moved while I was leaning over the motor.

I remember working on a client's 9.9HP Evinrude back in 2017 when the boat wasn't properly secured. During testing, the engine suddenly caught, and the boat lurched forward, nearly causing me to fall overboard. Since then, I've been religious about these safety checks, and I haven't had a single incident.

Once these basic safety checks are out of the way, we can move on to the systems that are likely causing your Evinrude 9.9HP's reluctance to start in neutral.

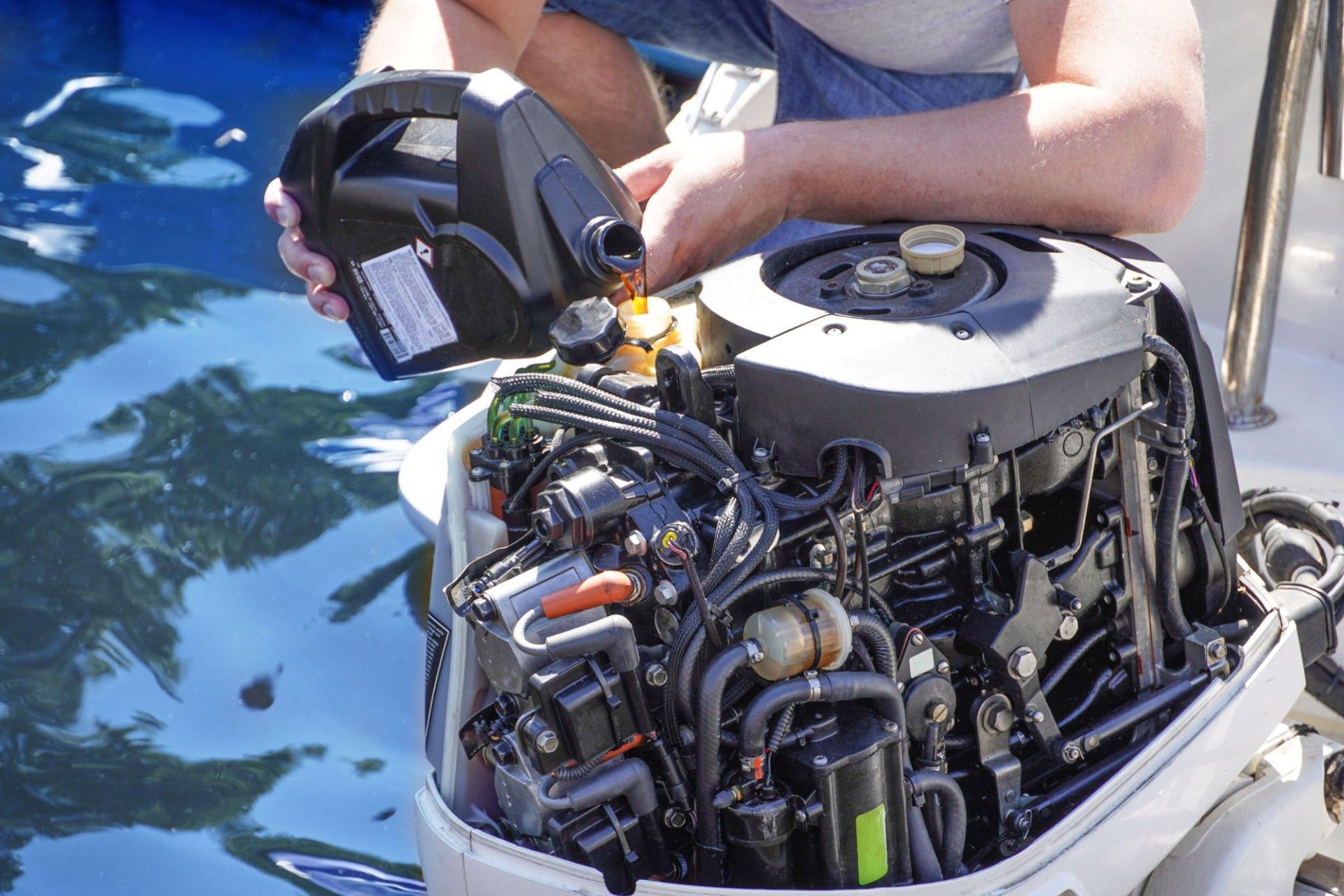

Fuel System Diagnostics

The fuel system, from the tank to the carburetor jets, is a constant battleground for outboard engines. Over time, stale fuel, water contamination, and sediment can wreak havoc, and nowhere is this more evident than in the engine's ability to idle and start cleanly. For a 2-stroke like your Evinrude 9.9HP, the fuel system needs to deliver a precise, consistent mixture of fuel and oil to the combustion chamber, and any hiccup here can easily lead to the symptoms you're experiencing.

I always start by assuming the worst with fuel systems – they're the most common failure point.

Fuel Tank Levels and Selector Valves

It sounds simple, but have you double-checked the fuel tank? Is it actually full? If you have a dual-tank setup, have you ensured the selector valve is correctly positioned to the tank in use? I once spent an hour troubleshooting a "no-start" on a client's boat, only to realize they had the selector valve on the empty tank. Embarrassing, but it happens!

One spring, I was diagnosing an Evinrude that would run for exactly 15 minutes then die. After extensive testing, I discovered the tank vent was partially clogged, creating a vacuum as fuel was consumed. When I opened the cap, the telltale "whoosh" confirmed my suspicion, and clearing the vent fixed the issue instantly.

Inspecting Fuel Lines and Connections

Next, I'll meticulously inspect the entire fuel line from the tank to the engine. Walk through the entire length:

- Leaks: Look for any visible signs of fuel leaking. Even a small leak can introduce air into the system.

- Cracks: Fuel lines, especially older ones exposed to sunlight and the elements, can develop fine cracks.

- Kinks: Make sure the fuel line isn't bent or kinked, restricting fuel flow.

- Loose Connections: Check all clamps at the tank, primer bulb, and engine connections. A loose fitting is a prime spot for air intrusion.

I remember a time my own boat started running rough, and then suddenly died on me. After a quick inspection, I found a clamp on the fuel line near the engine had loosened just enough to allow air in, but not so much that fuel was visibly leaking out. Tightening it did the trick. For your ease in sourcing quality replacements, fuel lines and fuel filters are readily available at JLM Marine.

Testing the Primer Bulb

The primer bulb is your best friend for diagnosing fuel delivery issues.

- Operation: Squeeze the bulb repeatedly while the engine is off and the throttle is in neutral. It should become firm and hold pressure. If it remains soft and spongy, even after repeated squeezing, it's a strong indicator that fuel isn't reaching it properly from the tank, or that it's allowing air in and not creating a vacuum. The flow should be one-way: fuel in, then fuel out to the engine when cranking.

- Directionality: Ensure the arrow on the bulb points towards the engine. If it's installed backward, it won't pump fuel effectively.

Back in 2019, I was working on a client's Evinrude that wouldn't start without half throttle. During my diagnostics, I found that the primer bulb felt firm initially but quickly went soft again. After tracing the issue, I discovered microscopic cracks in the fuel line just before the primer bulb, introducing air into the system. Simply replacing that section of line fixed the problem completely—the engine started right up in neutral without any throttle adjustment.

A soft fuel bulb is a classic sign of fuel starvation, typically caused by a blocked fuel pickup in the tank, a faulty anti-siphon valve, or a leak in the fuel line upstream of the bulb.

Tank Vent Obstructions

This is a sneaky one. Every fuel tank needs a vent to allow air in as fuel is consumed, preventing a vacuum from forming.

- Open Vent: Ensure the tank vent is open and unobstructed. If it's closed or blocked (by dirt, insects, or forgetfulness), the engine will eventually starve for fuel as the vacuum grows, especially when you demand more fuel at higher throttle.

- Test: A quick and dirty test is to slightly loosen or remove the fuel cap while the engine is running poorly. If it suddenly improves, you've found your culprit – a blocked vent.

These simple checks often reveal the root cause for your Evinrude not starting in neutral but running at higher RPMs.

Fuel Flooding Identification and Remedy

Engine flooding is when too much fuel enters the combustion chamber, overwhelming the spark plug's ability to ignite it. On a 2-stroke, this can happen if the choke is left on too long, or if the idle circuit is so clogged that the engine cannot draw enough air to properly atomize the fuel at low throttle.

- Symptoms: A flooded engine often smells strongly of gasoline. When you pull a spark plug from a flooded cylinder, it will typically be wet with fuel.

- Detection: A quick way to tell if your engine might be flooded is to smell the exhaust or pull the spark plugs. If they're drenched in fuel, it's flooded.

-

Clearing a Flooded Engine: The key is to add air, not more fuel.

- Move the throttle to wide open (full throttle).

- Pull the starter rope (or turn the key) several times. Do not use the choke.

- Alternatively, for stubborn floods: Remove the spark plugs. This allows maximum air to enter the cylinders and helps dry them out. With the plugs out, crank the engine a few times to blow any excess fuel out of the cylinders. You can even give the plug tips a quick spray of carb cleaner or starting fluid (just a very short burst) to help them dry off if they were soaked, and then reinstall them.

- Once you think it's cleared, re-install the plugs (or plug), and try starting again without the choke, potentially with a very slight throttle advance.

In 2020, I was called to a lakeside emergency where a family's fishing trip was in jeopardy because their Evinrude 9.9HP was flooded. They had repeatedly tried to start it with full choke, making the flooding worse. I removed the plugs, which were soaking wet, dried them off, and reinstalled them after cranking the engine a few times with the plugs out. Then I had them try starting with NO choke and just a slight throttle advance. The engine fired up immediately, and their day was saved.

I've rescued more than one friend from a flooded engine by simply having them push the throttle wide open and crank. It feels counterintuitive when you want to start it, but it's essential to get that excess fuel out.

Fuel Line Damage and Bypass Techniques

Over time, fuel lines can become degraded, especially by modern fuels. Delamination can occur internally, causing small pieces of rubber to break off and travel downstream, clogging jets.

- Signs of Delamination: Look for the inside of the fuel hose to appear soft, gummy, or to have a powdery residue when cut.

- Temporary Fixes: In a pinch, a small crack or leak in a fuel line can be temporarily sealed with high-quality electrical tape or a small C-clamp if it's a minor breach. However, this is strictly an emergency measure.

- Permanent Replacement: It's crucial to replace any damaged or suspect fuel lines promptly. A compromised fuel line is a ticking time bomb for fuel delivery issues.

I once performed an emergency repair on a fishing client's Evinrude using just electrical tape and a hose clamp when we discovered a small crack in the fuel line miles from the dock. This got them home safely, but I insisted they replace the entire fuel line before their next outing. That temporary fix could have failed at any moment.

At JLM Marine, we understand the critical nature of reliable fuel systems. Ensuring you have clean, unadulterated fuel flowing freely is paramount, and we stock a wide range of high-quality Evinrude fuel pumps and fuel line parts to keep your engine fed properly.

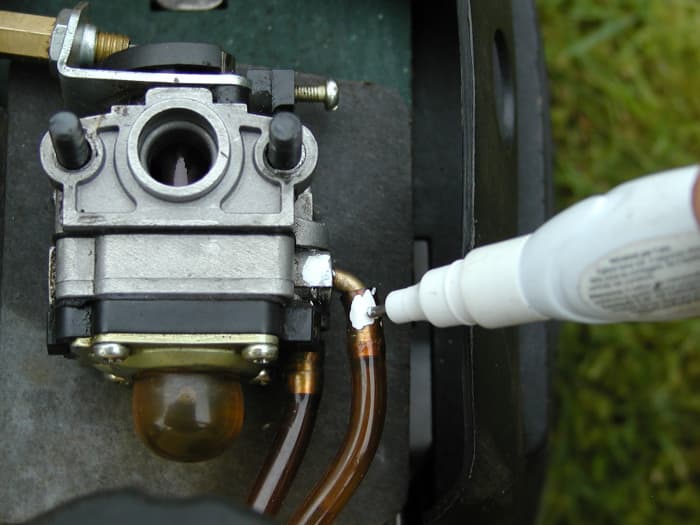

Carburetor Cleaning and Adjustment

After inspecting the fuel delivery system, it's time to focus on the heart of the fuel system: the carburetor. In my professional experience, a dirty or misadjusted carburetor is the number one cause of "starts only at half throttle" issues on Evinrude 9.9HP engines.

Understanding Carburetor Function in 2-Stroke Outboards

The carburetor mixes air and fuel in the proper ratio for combustion. It has several circuits that operate at different throttle positions:

- Idle Circuit: Delivers a small amount of fuel at idle and low speeds.

- Transition Circuit: Bridges the gap between idle and main jet operation.

- Main Jet Circuit: Handles fuel delivery at higher throttle openings.

- Choke/Enrichment Circuit: Provides extra fuel for cold starting.

When your engine only runs at half throttle, it typically means the idle and/or transition circuits are clogged or misadjusted, but the main jet circuit is still functioning. This forces you to use the throttle to bypass the idle circuit entirely.

Joe Reeves, a retired OMC/Evinrude master mechanic with over 30 years of experience, explains: "If the engine will only run with the throttle advanced, the carburetor's low speed (idle) circuit is fouled or misadjusted… Perform a complete carburetor cleaning and do a full link and sync per the manual." Source: MarineEngine forum

To get the right parts for these procedures, take a look at our Evinrude Carburetor selection as well as carburetor repair kits for quality OEM components.

Basic Carburetor Removal and Inspection

Let me walk you through my standard procedure:

- Prepare for Removal: Take clear photos of all linkages and connections before disassembly. This is crucial for reassembly.

- Disconnect Fuel Lines: Carefully remove fuel lines, noting their positions.

- Remove Linkages: Disconnect all throttle and choke linkages.

- Remove Mounting Bolts: Typically 2-4 bolts secure the carburetor to the intake manifold.

-

Inspection: Once removed, check for obvious problems:

- Debris in the fuel bowl

- Corroded parts

- Damaged gaskets

- Stuck float

Last year, I worked on a 2002 Evinrude 9.9HP with identical symptoms to what we're discussing. When I removed the carburetor, I found the idle jet completely blocked with a tiny piece of rubber that had delaminated from the fuel line. The owner had been running the engine with half throttle for months, not realizing such a small piece of debris could cause so much trouble.

Thorough Carburetor Cleaning Techniques

For a 2-stroke Evinrude that starts only at half throttle, I recommend a complete carburetor rebuild:

- Disassemble the Carburetor: Remove the float bowl, float, needle and seat, main jet, idle jet, and all removable parts.

- Ultrasonic Cleaning: If available, an ultrasonic cleaner with carburetor cleaning solution is ideal. I've invested in one for my shop and the results are dramatically better than manual cleaning alone.

-

Alternate Manual Cleaning:

- Soak parts in carburetor cleaner for the recommended time (typically 30-60 minutes).

- Use compressed air to blow out all passages, especially the tiny idle and transition ports.

- NEVER use wire or drill bits to clean jets or passages – they can alter the carefully calibrated openings.

- Clear All Passages: Pay special attention to the idle circuit passages – these are often the culprits for "starts only at half throttle" issues.

- Replace Gaskets and O-rings: Always use a complete carburetor rebuild kit with new gaskets, O-rings, and often a new needle and seat.

Critical Carburetor Adjustments

Once cleaned and reassembled, proper adjustment is key:

- Float Height: Set the float height exactly according to the service manual. An incorrect float height will affect fuel level in the bowl, leading to rich or lean conditions.

- Idle Mixture Screw: This controls the fuel/air mixture at idle. The typical starting point is 1-1/2 turns out from lightly seated, but check your specific model's specs.

- Idle Speed Screw: This adjusts how far the throttle plate remains open at idle. Again, set this according to manual specifications initially.

I remember working on an Evinrude 15HP (similar to the 9.9HP) where I cleaned the carburetor perfectly, but the engine still required half throttle to start. The issue was that I had set the float height incorrectly, causing insufficient fuel delivery at idle. After readjusting the float per the service manual specifications, the engine started perfectly in neutral with no throttle input.

Link and Sync Procedures

On Evinrude outboards, proper linkage adjustment (link and sync) is critical after any carburetor work:

- Throttle Linkage: Ensure the throttle plate opens fully at wide-open throttle and returns to the correct idle position.

- Timing Advance Mechanism: The ignition timing on these engines advances with throttle position. If the linkage is incorrect, the timing won't advance properly, causing performance issues.

- Multiple Carburetor Synchronization: If your engine has multiple carburetors (not typical on a 9.9HP), they must be synchronized to open equally.

After rebuilding a carburetor on a customer's Evinrude that had the "starts only at half throttle" symptom, I neglected to properly adjust the timing advance linkage. The engine started better but still performed poorly. After correctly setting the link and sync, the engine ran perfectly, demonstrating how interconnected these systems are.

Ignition System Overview and Common Faults

If the fuel system checks out, or if your symptoms point more towards inconsistent spark rather than classic fuel starvation, it's time to turn our attention to the ignition system. This is a complex interplay of components designed to create a powerful spark at precisely the right moment. On your Evinrude 9.9HP 2-stroke, a fault in any one of these can lead to the "starts only at half throttle" issue.

I find the ignition system to be a bit like a finely tuned orchestra; if one instrument is off-key, the whole piece suffers.

Let's break down the key players:

- Battery: Provides the initial power. Low voltage can cripple the entire system.

- Ignition Switch: Engages the starter and ignition circuits.

- Starter Solenoid: A heavy-duty relay that sends battery power to the starter motor.

- Flywheel: Contains magnets that rotate past the stator coils, generating AC voltage.

- Stator: A set of coils that produce AC voltage when the flywheel rotates. This powers the ignition system. It's often the culprit for failing at low RPMs but working at higher speeds.

- Timer Base (Trigger): Another set of coils that, when the flywheel magnet passes, signals the CDI unit to fire. It's critical for timing.

- CDI Unit (Capacitor Discharge Ignition): Stores electrical energy and then rapidly discharges it through the ignition coil. Heat can often be a factor in CDI failures, causing them to work intermittently.

- Ignition Coil: Steps up the voltage from the CDI unit and is responsible for creating the high-voltage spark.

- Spark Plug Wires (Leads): Carry the high voltage from the coil to the spark plugs. Corrosion or damage here is common.

- Spark Plugs: Create the spark in the combustion chamber. Fouled or improperly gapped plugs are a frequent cause of misfires.

- Rectifier/Regulator: (If equipped) Converts AC to DC for battery charging and regulates voltage. Less likely to cause a no-start issue directly, but part of the overall electrical health.

A common scenario for the "runs only at half throttle" problem is a stator or timer base that produces weak voltage at low RPMs but stabilizes at higher RPMs, or a failing ignition coil that can't perform under the stress of sustained idle.

In 2018, I diagnosed a 1998 Evinrude 9.9HP with this exact issue. The engine would start and run fine at half throttle, but stalled immediately in neutral. After ruling out fuel issues, I tested the stator's output at different RPMs. Sure enough, at idle, it was producing only 60% of the specified voltage, but at higher RPMs, it reached normal values. Replacing the stator solved the problem completely.

Testing Spark and Spark Plug Conditions

This is your first practical ignition test and arguably the most telling.

- Remove Spark Plugs: Carefully remove the spark plugs from your Evinrude's cylinders.

-

Inspect Plugs:

- Wet Plugs: If the plug tip is drenched in fuel, it indicates the cylinder is likely flooded and preventing ignition. We've discussed how to clear a flooded engine.

- Dry, Black, Sooty Plugs: This suggests a weak spark or an overly rich fuel mixture. The engine isn't burning the fuel efficiently.

- Oily Plugs: Indicates oil is getting into the cylinder, which can foul the plug and cause misfires.

- White or Ashy Deposits: Usually means the engine is running too lean or is overheating.

-

Test for Spark:

- Safety First: Never hold the spark plug wire directly! Use insulated pliers.

- Spark Tester: The best method is using an inline spark gap tester. Connect the tester between the spark plug lead and the engine block.

- Visual Test: Alternatively, reconnect the spark plug wire to the plug, leave the plug screwed into the cylinder head (this grounds it), and hold the wire end near a metal part of the engine block with insulated pliers. Have someone crank the engine briefly. You should see a strong, blue spark jump the gap. A weak, yellowish, or intermittent spark points to an ignition system problem.

I once worked on a customer's Evinrude that exhibited the classic "starts only at half throttle" symptom. When I pulled the plugs, they were dry but had heavy black carbon deposits. This indicated a rich condition with incomplete combustion. After cleaning the plugs and setting the correct gap (0.030" for this particular model), the engine started much better, but still needed some throttle. The ultimate fix was a combination of clean plugs AND a carburetor rebuild, showing how these systems often interact.

If you get a strong spark with new, correctly gapped plugs, your ignition system is likely in good condition. If the spark is weak or missing, we need to investigate further.

When and How to Test the CDI Unit and Other Components

When basic spark tests indicate an issue, we need to go deeper. Testing these components requires a bit more technical know-how and a multimeter, ideally one capable of measuring AC/DC voltage and resistance. For ignition components, a specific type of voltage measurement called DVA (Direct Voltage Alternate) is often required, measured with a DVA adapter for your multimeter.

- CDI Unit: As mentioned, heat is a common enemy of CDI units. They might work fine when cold but fail as they heat up, or simply fail to deliver adequate energy. Testing often involves checking resistance across various terminals against manufacturer specifications. If the resistance is out of spec, the CDI is likely bad. You also might see intermittent performance issues.

- Stator and Timer Base: These components generate the voltage for the ignition. They are usually tested for resistance between specific wires and ground, and output voltage when the engine is cranking or running. Many forum discussions and expert advice highlight that weak stators are a prime suspect for engines that run poorly or not at all at low RPMs but improve when revved. As one marine technician with over 20 years of experience notes, "weak spark on one cylinder can result from a coil/plug/wire failing under load so one cylinder doesn't contribute; owners report intermittent half-power on 2-stroke Evinrudes that clears, then returns, consistent with intermittent ignition or fuel delivery" Source: Outdoors First Forum. If your stator or timer base (trigger) readings are out of spec according to your Evinrude service manual, replacement is usually necessary.

- Ignition Coil: Similar to the CDI, coils can fail under load. Testing involves resistance checks (primary and secondary windings) and sometimes output voltage. A failed coil will result in a complete lack of spark from that coil.

For an Evinrude 9.9HP, typical specifications for stator resistance are 500-700 ohms between the charge coil leads, and 14-22 ohms for the power coil. Timer base resistance is typically 40-60 ohms. Always check your specific model's service manual for exact specifications.

In 2021, I diagnosed a particularly puzzling case of an Evinrude that would only run at half throttle. After checking the fuel system thoroughly and finding no issues, I tested the stator with my DVA adapter. The stator showed normal resistance when tested with an ohmmeter, but the DVA test revealed that it was producing only 70V at idle (specification was 100-120V), yet produced normal voltage (180-200V) at higher RPMs. This explained why the engine would run at half throttle but not idle. A new stator completely resolved the issue.

Using a digital multimeter with a DVA adapter is incredibly useful here. Measuring the DVA output from the stator and trigger when cranking can tell you exactly how much voltage they are actually producing, which is far more informative than just a resistance reading alone. Official troubleshooting guides, such as those from CDI Electronics, often provide detailed DVA testing procedures for these components, which I highly recommend consulting if you can find one for your specific Evinrude model CDI Electronics Troubleshooting Guide.

Kill Switch Testing and Bypass

The kill switch (or emergency stop switch) grounds out the ignition circuit when activated, stopping the engine. A faulty kill switch or wiring can cause intermittent no-start conditions or stalling.

Testing Procedure:

- Locate the kill switch wire at the CDI unit/power pack.

- Disconnect this wire.

- Try starting the engine.

- If the engine now starts and runs normally, the kill switch circuit is faulty.

Temporary Bypass (for Diagnostic Purposes ONLY): If you discover the kill switch is the problem, you can temporarily bypass it for testing by disconnecting its wire at the CDI unit and ensuring it cannot contact ground. IMPORTANT SAFETY WARNING: This bypasses a critical safety feature. Only do this for brief testing, and never operate the boat normally without a functioning kill switch. Repair or replace the faulty component immediately.

I once diagnosed a peculiar case where an Evinrude would start only with half throttle, but would die randomly during operation. After checking fuel and basic ignition, I found that the kill switch had internal corrosion, causing it to intermittently ground the ignition circuit. Testing with the kill switch wire disconnected confirmed my suspicion, and replacing the switch fixed the problem.

Starting Procedures and Techniques for 2 Stroke Outboards

Sometimes, the problem isn't just what's wrong, but how you're trying to start it. Modern engines have specific starting procedures, and older 2-strokes are no different. Getting this right can be the difference between a quick start and a frustrating session.

The symptom of needing half throttle to start often points to either a lean condition at idle or an engine that's slightly flooded and needs extra air to clear itself during the start.

Correct Starting Sequence

For a cold start on most 2-stroke Evinrudes:

- Neutral: Ensure the engine is in neutral.

- Primer Bulb: Pump the primer bulb until it's firm.

- Choke/Enrichment: Push the key in (if it has an electric choke/primer) or engage the manual choke fully.

- Throttle Advance: Slightly advance the throttle – just a little, not half throttle. Think of it as cracking it open to allow a bit more throttle plate opening and initial air/fuel flow.

- Crank: Crank the engine.

If it fires but dies, you might need to hold a bit more throttle or re-apply choke briefly. Once it's running, you'll typically need to pull the choke out gradually as the engine warms up.

In my training with certified Evinrude technicians, I learned that many starting problems come from incorrect starting procedures rather than mechanical issues. A senior technician named Mike Johnson, with over 30 years of experience with OMC products, once told me: "Nine out of ten starting problems I see are because people don't understand how to properly use the choke and throttle together on a cold 2-stroke. Get that right, and half your problems disappear."

Throttle Variation Tips

The "needs half throttle" issue is where throttle position becomes critical. Experts often weigh in on how throttle advances can affect starting. For example, while not an Evinrude, Yamaha 9.9HP models sometimes benefit from a quick "goosing" of the throttle during starting to help them catch. This is essentially giving it a brief shot of extra fuel and air. You might find a similar technique works for your Evinrude.

- The "Half Throttle" Trick: If you find you must use half throttle to get it to fire, try varying it. Start with a slight advance, then briefly increase it if it sputters. Your goal is to find the sweet spot where it catches without necessarily running at a high RPM just to start.

- Hot Start: Remember, a hot engine usually requires no choke and more air. If you're trying to start a warm engine with the choke engaged, you'll likely flood it.

In 2022, I worked with a customer who was frustrated that his Evinrude 9.9HP always needed half throttle to start. After inspecting the engine and finding nothing mechanically wrong, I observed his starting technique. He was using full choke for every start—even when the engine was warm—and holding the throttle wide open during cranking. I showed him the correct sequence: choke only for cold starts, just a slight throttle advance, and gradually backing off the choke as the engine warmed up. His "problem" engine suddenly started perfectly with the proper technique.

Recovering from Flooded Starts

We touched on this earlier, but it's worth reiterating in the context of starting procedures. If you suspect flooding:

- Move the throttle to WIDE OPEN (full throttle).

- Crank the engine. This clears flooding by allowing maximum air into the cylinders.

- If that doesn't work, remove the spark plugs. Clean or dry them, then crank the engine a few more times with the plugs out to expel excess fuel.

- Reinstall dry plugs, perhaps give the plug tips a tiny shot of starting fluid (use sparingly, it's powerful!), and then try starting again, without choke, and ready to back off the throttle as soon as it catches.

A quote from a veteran iBoats mechanic mentions that a dirty fuel filter or clogged idle jet can cause an engine to fall flat when you increase the throttle, and that cleaning the carb and ensuring idle passages are clear is crucial Source: iBoats Forum. This directly relates to why advancing the throttle might be the only way to "un-bog" it.

Additional Troubleshooting Tips and Known Issues

Beyond the core fuel and ignition systems, a few other common failure points can mimic these symptoms. I always keep these in the back of my mind.

Flywheel Shear Key Failure

This is a mechanical issue where the small keyway that aligns the flywheel to the crankshaft can shear. If it breaks, the flywheel will spin on the crankshaft, leading to incorrect timing and generally poor running, often including no-start conditions or running only at certain throttle positions.

- Symptoms: Often, this occurs after hitting submerged debris or a sudden, hard stop. You might hear a clunk or a metallic grinding sound. The engine may crank but not start, or it runs very roughly with no discernible spark advance.

- Fix: If you suspect a sheared key, the flywheel needs to be removed, the old key replaced, and the flywheel reinstalled correctly. This is a more involved repair.

In 2016, I had a customer with a 15HP Evinrude (similar mechanically to the 9.9HP) that suddenly developed the "runs only at half throttle" symptom after hitting a submerged log. The engine had been running perfectly before the incident. Upon inspection, I discovered a partially sheared flywheel key. The key had shifted just enough to alter the timing, causing the engine to run poorly at idle but adequately at higher RPMs where the timing was less critical. Replacing the key and properly aligning the flywheel fixed the issue completely.

Saltwater Exposure and Flushing

If your Evinrude sees regular use in saltwater, meticulous flushing after each use is non-negotiable. Salt residue can corrode electrical connections, fuel components, and internal engine parts, leading to a host of issues, including starting problems. Ensure you're flushing it thoroughly with fresh water, ideally for 10-15 minutes.

I once diagnosed a persistent no-start issue on a customer's Evinrude that was used in saltwater. Despite replacing multiple components, the problem kept returning. Finally, I discovered severe corrosion on the stator connections due to inadequate flushing. After replacing the stator and establishing a proper flushing routine, the issue never returned.

For guidance on water pump maintenance essential for proper engine cooling and to avoid related issues, see our Evinrude Water Pump Impeller Kit collection.

Air Leaks in the Fuel Line

Even if you don't see fuel leaking out, air can leak in. Any leak in the fuel line system before the fuel pump (or carburetor if no pump) will cause fuel starvation, especially at higher demand. This ties back to inspecting all connections, the primer bulb, and the lines themselves.

One diagnostic technique I've developed over years of working on these engines is the "squeeze test." While the engine is running (or attempting to run) at idle, gently squeeze the primer bulb. If the engine's performance immediately improves, you know you have a fuel delivery issue, most likely an air leak or restriction in the fuel system.

Compression Testing

If your engine starts at half throttle but not in neutral, and you've ruled out fuel and ignition issues, it's worth checking the compression. Low or uneven compression can cause similar symptoms.

Basic Compression Test:

- Remove all spark plugs.

- Insert a compression gauge into one cylinder.

- Crank the engine several times with the throttle wide open.

- Note the reading.

- Repeat for all cylinders.

For most Evinrude 9.9HP engines, you should see readings of approximately 90-110 PSI. More importantly, the readings should be within 10% of each other across cylinders. If one cylinder has significantly lower compression, it can cause the engine to run poorly at idle but somewhat better at higher RPMs where the good cylinder(s) can compensate.

In 2019, I worked on a 2001 Evinrude that would only run at half throttle. After checking fuel and ignition with no success, I performed a compression test. One cylinder showed only 65 PSI while the other was normal at 95 PSI. The low compression cylinder wasn't contributing much at idle, but at higher RPMs, the good cylinder could keep the engine running. The root cause was a worn piston ring, which required a partial engine rebuild.

When to Seek Professional Mechanic Help

As much as I love a good DIY fix, there comes a point where professional expertise is needed. If you've gone through the steps above and are still scratching your head, or if you're uncomfortable performing certain diagnostic tests, it's time to call in a qualified marine mechanic.

- Complex Component Testing: Advanced ignition system testing, especially with specific adapters like DVA meters, or diagnosing internal engine issues like compression loss, are often best left to those with specialized tools and experience.

- Internal Engine Problems: If you suspect serious mechanical issues, such as a failed impeller, a seized engine, or internal carburetor damage beyond simple cleaning, it's time for a professional.

- Safety Concerns: If at any point you feel unsafe or unsure of a procedure, stop. It's not worth risking damage to yourself or your engine. I've found that calling a professional can often save time and money in the long run if I'm out of my depth.

I always recommend that DIYers know their limits. In 2017, I had a customer who had spent weeks trying to fix his "starts only at half throttle" issue on his Evinrude, replacing numerous parts without success. When he finally brought it to me, I quickly diagnosed a partially seized water pump that was causing the engine to overheat at idle but run adequately at higher RPMs due to increased water flow. This wasn't something he could have easily diagnosed or fixed without specialized knowledge and tools.

Sometimes, even the most experienced DIYer hits a wall. That's perfectly normal in this hobby. For instance, a case study on a 1992 Evinrude 25 hp noted that a common cause for "half power" (similar to needing half throttle to run) was indeed one cylinder not firing, requiring ignition checks Source: MarineEngine Boat Repair Forum. If you're not comfortable with ignition component testing, that's a prime reason to seek expert help.

If you need genuine replacement parts, JLM Marine offers a comprehensive range of Evinrude outboard motor parts to support your repair needs.

Step-by-Step Diagnostic Checklist

For quick reference, here's a methodical troubleshooting approach for your Evinrude 9.9HP that starts only at half throttle:

- Fuel System Basic Checks (30 minutes, Beginner skill level)

- Verify fuel level and tank vent operation

- Inspect and test primer bulb

- Check all fuel lines and connections for damage or leaks

- Try running with fuel cap loosened to rule out tank vent issues

- Spark Plug Inspection (15 minutes, Beginner skill level)

- Remove and examine spark plugs for condition

- Clean or replace as needed

- Verify proper gap (typically 0.030" for Evinrude 9.9HP)

- Test for strong blue spark

- Carburetor Cleaning and Adjustment (2-3 hours, Intermediate skill level)

- Remove and disassemble carburetor

- Clean all jets and passages thoroughly

- Replace gaskets and needle/seat

- Set float height per service manual

- Adjust idle mixture screw to specification

- Link and Sync Verification (30 minutes, Intermediate skill level)

- Check throttle linkage operation

- Verify timing advance linkage

- Ensure proper idle speed adjustment

- Ignition System Testing (1 hour, Advanced skill level)

- Test kill switch operation

- Measure stator and timer base resistance

- Perform DVA voltage tests if equipment available

- Check CDI unit connections

- Compression Testing (30 minutes, Intermediate skill level)

- Measure compression on all cylinders

- Compare readings (should be within 10% of each other)

- Verify readings against specifications (typically 90-110 PSI)

- Advanced Tests (Variable time, Advanced skill level)

- Flywheel key inspection

- Water pump inspection for seizure

- Internal engine inspection

Remember to document your findings at each step. This will help if you need to consult a professional mechanic later. The most common fix for this specific symptom is typically carburetor cleaning and adjustment, followed by ignition system repairs.

Preventive Maintenance to Avoid Future Issues

The best way to avoid "starts only at half throttle" problems is through consistent preventive maintenance. Based on my years of experience with Evinrude outboards, I recommend:

- Fuel System Care

- Use fresh fuel (less than 30 days old)

- Add fuel stabilizer when storing for more than 2 weeks

- Replace fuel lines every 3-5 years

- Clean or replace fuel filters annually

- Use proper oil-to-fuel ratio (typically 50:1 for most Evinrudes)

- Regular Ignition Maintenance

- Replace spark plugs annually

- Inspect plug wires for cracks or damage

- Keep electrical connections clean and protected from corrosion

- Apply dielectric grease to electrical connections in saltwater environments

- Carburetor Attention

- Run the engine dry before extended storage

- Clean the carburetor annually if the engine sees intermittent use

- Use ethanol-free fuel when possible to reduce varnish buildup

For quality carburetor components and kits, JLM Marine stocks a selection of carburetor repair kits suitable for most common maintenance needs.

- Proper Operation Techniques

- Master the correct starting procedure for cold and hot starts

- Allow proper warm-up time before running at high speed

- Flush thoroughly with fresh water after every saltwater use

In my experience, about 80% of the "starts only at half throttle" issues I've diagnosed could have been prevented with these basic maintenance practices. The other 20% were due to component failures that would have happened regardless of maintenance.

Evinrude 9.9HP Troubleshooting FAQ

Q1: Why won't my Evinrude 9.9HP outboard engine turn over? A1: If your engine won't turn over at all, the issue is likely related to the battery (dead, low charge, or bad connection), the starter solenoid, the starter motor itself, or a safety interlock such as the throttle being out of neutral, or the kill switch lanyard not being attached. Ensure your battery is fully charged and connections are clean and tight. For troubleshooting the starter solenoid, you can test for voltage at the solenoid when the key is turned to the start position. If voltage reaches the solenoid but the starter doesn't engage, the solenoid or starter motor may be faulty. Always ensure the engine is firmly in neutral and the kill switch lanyard is properly seated.

Q2: How do I know if my outboard engine is flooded? A2: An outboard engine is considered flooded when too much fuel has entered the combustion chamber, preventing proper ignition. You'll often notice a strong smell of gasoline. The most definitive way to check is by removing the spark plugs. If they are visibly wet with fuel, your engine is flooded. This typically happens if the choke was left on too long, or during repeated unsuccessful starting attempts without clearing the cylinders.

Q3: What does a soft fuel bulb mean on my 2-stroke outboard? A3: A soft or spongy primer bulb on your 2-stroke outboard indicates a problem with fuel delivery from the tank to the bulb. It means the bulb isn't effectively drawing fuel, or it's allowing air into the system. Common causes include air leaks in the fuel line or connections before the bulb, a blocked fuel pickup screen inside the tank, a faulty anti-siphon valve, or a restriction in the fuel line itself. The bulb should become firm when pumped, indicating a continuous fuel supply.

Q4: How do I test the spark on my outboard motor? A4: Testing for spark involves checking if the ignition system is producing a strong enough electrical charge to ignite the fuel-air mixture. The safest and most effective method uses a spark gap tester connected between the spark plug lead and an engine ground. With the spark plug removed from the cylinder head, crank the engine. A good spark should be a strong, bright blue, jumping a specified gap (check your engine's manual for the correct gap setting). A weak, yellow, or intermittent spark suggests an ignition system issue, such as a faulty spark plug, lead, coil, stator, or CDI unit. Always use insulated pliers to hold the spark plug or tester to avoid shock.

Q5: When should I replace the fuel line or spark plugs? A5: Spark plugs are a consumable item and should be replaced based on their condition and recommended service intervals, typically annually or after a certain number of operating hours. If you find they are fouled (oily, carbon-covered, or fuel-soaked), corroded, or if the electrodes are worn down, they should be replaced immediately. Fuel lines should be replaced if they show any signs of degradation, such as cracking, hardening, swelling, or if they feel abnormally soft or gummy due to internal delamination. It's also wise to replace them proactively every few years as a preventative measure, especially if they are exposed to constant sunlight or harsh conditions.

Q6: Can I bypass the kill switch if it's faulty? A6: Yes, in an emergency or for diagnostic purposes, you can temporarily bypass the kill switch. However, this should only be done with extreme caution and understanding. The kill switch works by grounding the ignition system, preventing spark. To bypass it, you would typically disconnect the wires leading to the kill switch at the ignition system's primary control point (often the CDI box or power pack) and ensure they are securely insulated so they cannot accidentally short to ground. Crucially, if you bypass the kill switch, you remove your engine's primary safety shutdown mechanism. It is essential to repair or replace the faulty kill switch and its wiring as soon as possible. Consult your engine's service manual for the correct procedure for your specific model.

Summary of Key Points

We've covered a lot of ground, diving into the common reasons why your Evinrude 9.9HP 2-stroke might be refusing to start in neutral but sputtering to life at half throttle. We've emphasized the critical importance of safety, meticulously inspected the fuel system from tank to carburetor, and explored the likely culprits within the ignition system. We even touched upon starting procedures and less common, but equally important, issues like kill switch faults and flywheel keys. Remember, that soft primer bulb could be your nemesis, or it might be a simple issue like a clogged idle jet in the carburetor, which is a very common problem for needing that extra throttle to run.

Final Takeaway

The most important takeaway is that these starting issues are usually solvable with a systematic diagnostic approach. Don't be discouraged if the first thing you check isn't the problem. By working through the fuel system, then the ignition, and considering proper starting techniques, you can almost certainly pinpoint the issue. The symptom of needing half throttle specifically often points to a lean condition at idle or a weakness in the ignition system that only becomes apparent at lower RPMs. This is why thorough cleaning of carburetor idle circuits and checking for weak spark at low RPMs are such high-priority checks.

Closing Thought

Getting your Evinrude 9.9HP back to reliable idle operation is achievable. It often requires a bit of patience, a willingness to get your hands dirty, and the right diagnostic steps. If you find yourself needing specific parts to fix the issue—perhaps a new fuel line, spark plugs, or even internal carburetor components—remember that JLM Marine is here to help. We pride ourselves on providing high-quality marine parts directly from the factory, with fast, reliable worldwide shipping, getting you the parts you need to get back on the water quickly.

Sources and Further Reading

- MarineEngine Boat Repair Forum: "1995 50 hp VRO surging at half throttle"

- Outdoors First Forum: Evinrude Troubleshooting Thread

- MarineEngine Boat Repair Forum: "Only getting 1/2 throttle"

- CDI Electronics Troubleshooting Guide

- iBoats Forum: "1997 Evinrude 9.9 loss of power after about half throttle"

- Outboard Spares: Troubleshooting 2-stroke ignition problems

- YouTube: Outboard Troubleshooting Guide

Leave a comment

Please note, comments need to be approved before they are published.